Window hinge joint method for erection of suspension bridge steel truss stiffening girder

A technology of stiffened beams and steel trusses, which is applied in bridge construction, bridge erection/assembly bridges, etc., and can solve the problems of long construction period, unfavorable stress on the stiffened beam structure, and the inability to ensure stress-free installation at the temporary joint of the stiffened beam section, etc. problem, to achieve the effect of process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

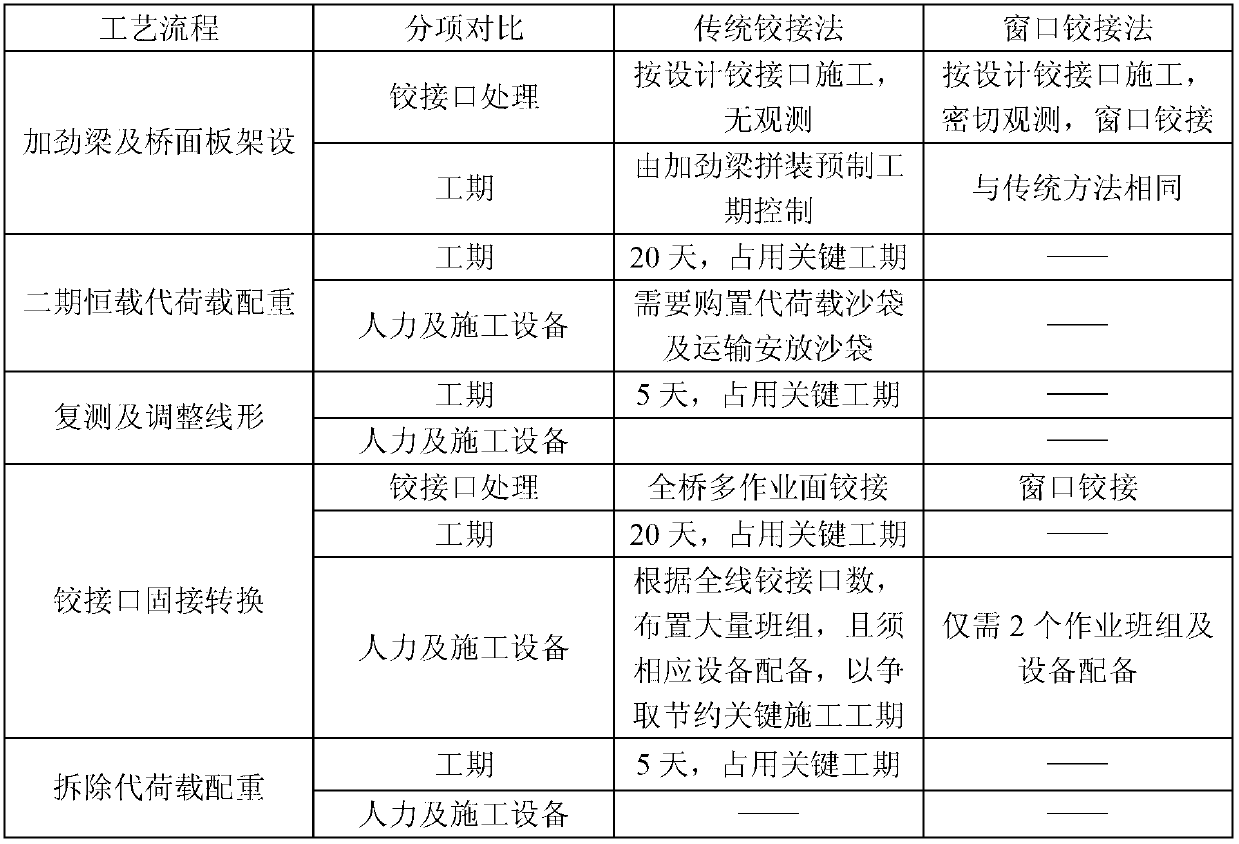

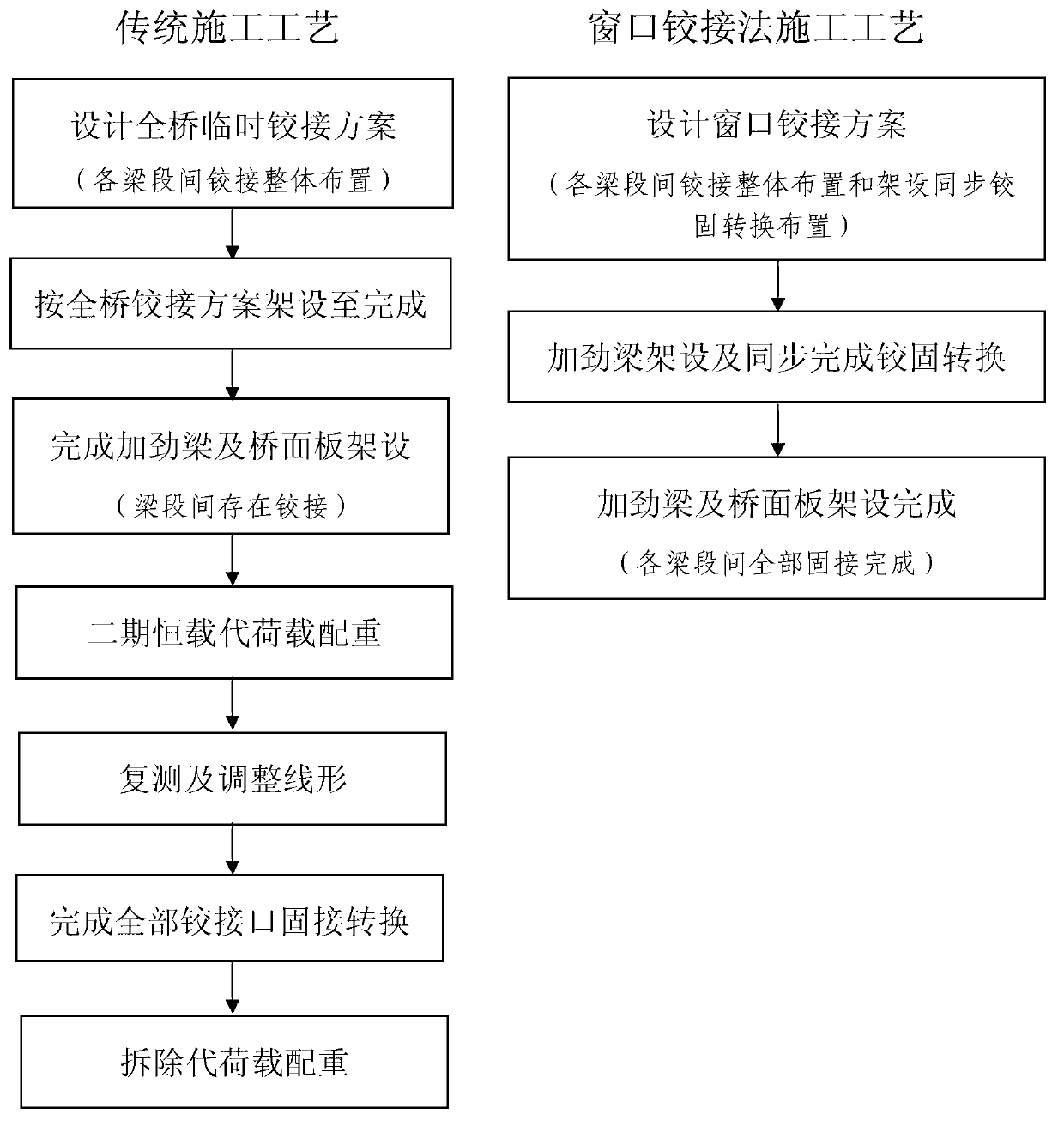

[0013] Compared figure 1 It can be seen that in the erection stage of the stiffened beam, the overall scheme of the temporary hinge of the whole bridge of the stiffened beam is reasonably set according to the lifting capacity of the construction equipment and the force requirements of the stiffened beam structure. During the construction process or during the installation of the bridge deck, using the linear changes of the installed stiffening beams during the construction process, when the distance between the temporary hinge joints meets the requirements, and the internal force of the subsequent construction process after consolidation will not exceed the force limit of the component, the hinge will be carried out immediately. Then, the temporary joints are fixed step by step; before all the stiffening girders are erected or the bridge deck is installed, all the temporary joints are completed. Therefore, in the traditional construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com