Symmetry degree Measuring method of ball valve two end faces

A measurement method and technology of both ends, applied in the field of measurement, can solve problems such as sliding door jamming, and achieve the effects of easy function realization, simple measurement method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

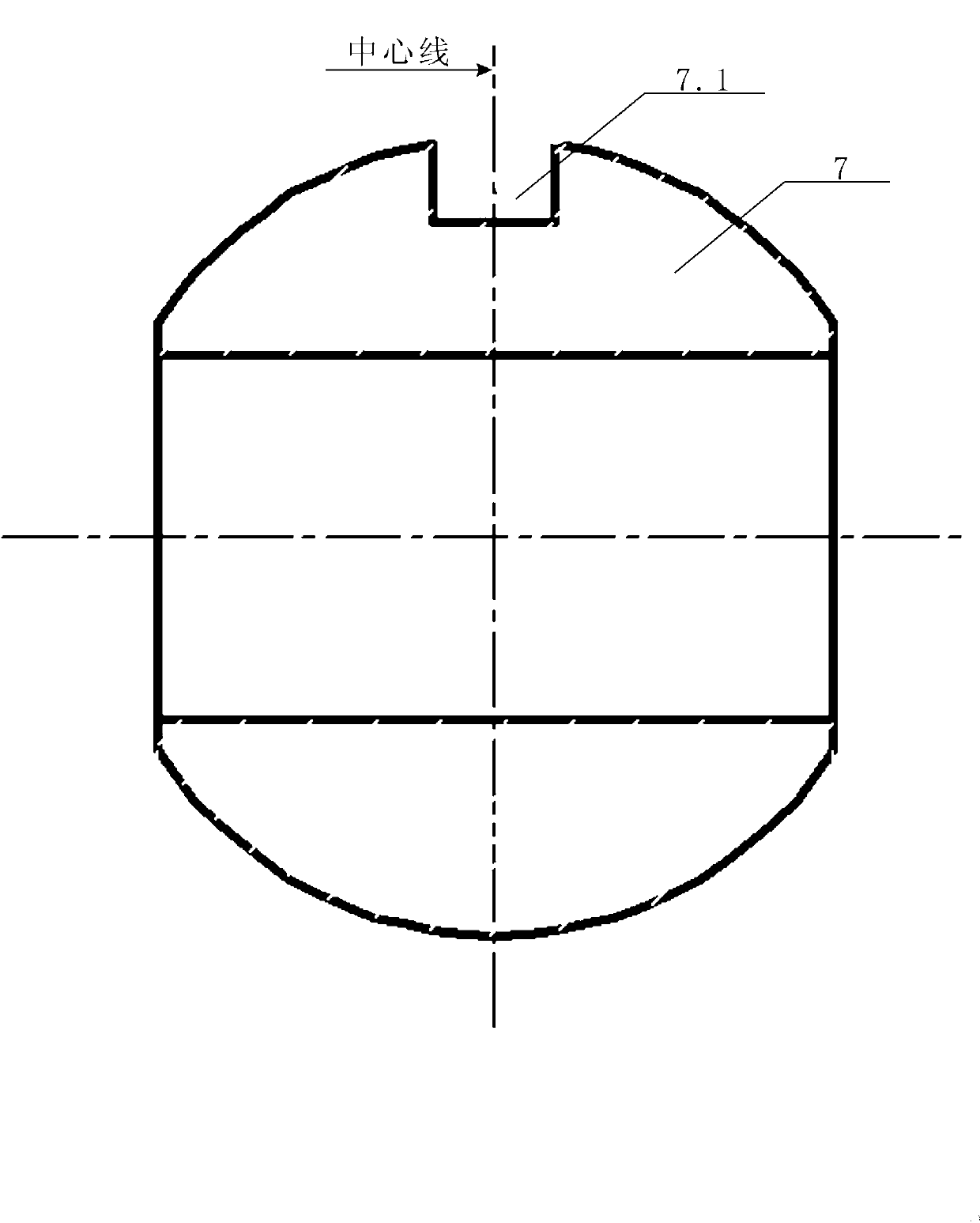

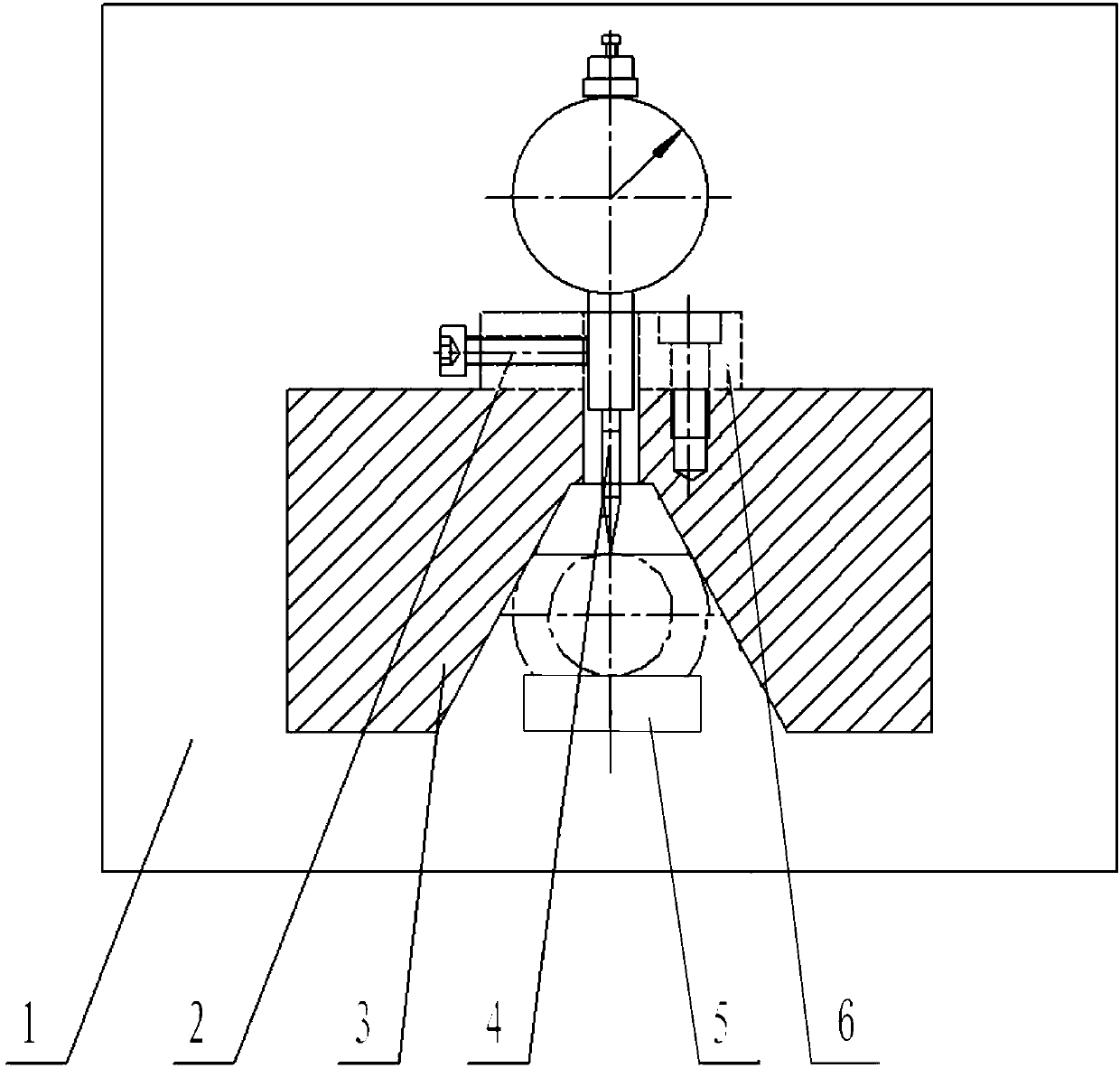

[0019] The invention is a method for measuring the symmetry of the two ends of a ball valve, combining figure 1 The two ends of the ball valve 7 refer to the A surface and the B surface. The distance between the A surface and the center line of the ball valve is equal to the distance between the B surface and the ball valve center line. The two ends of the surface have equal symmetry. Only the A surface and the B surface are relative to the center of the ball valve. The higher the symmetry of the line, the higher the symmetry of the guide groove 7.1 relative to the A surface and the B surface, so the measurement method of the present invention is very suitable for the measurement of symmetry such as balls with two ends, and the measurement method is simple, fast and accurate .

[0020] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com