Compressor starting method and apparatus

一种压缩机、最佳启动的技术,应用在起动的装置、机器/发动机、启动器零部件等方向,能够解决信息损失、启动失败等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

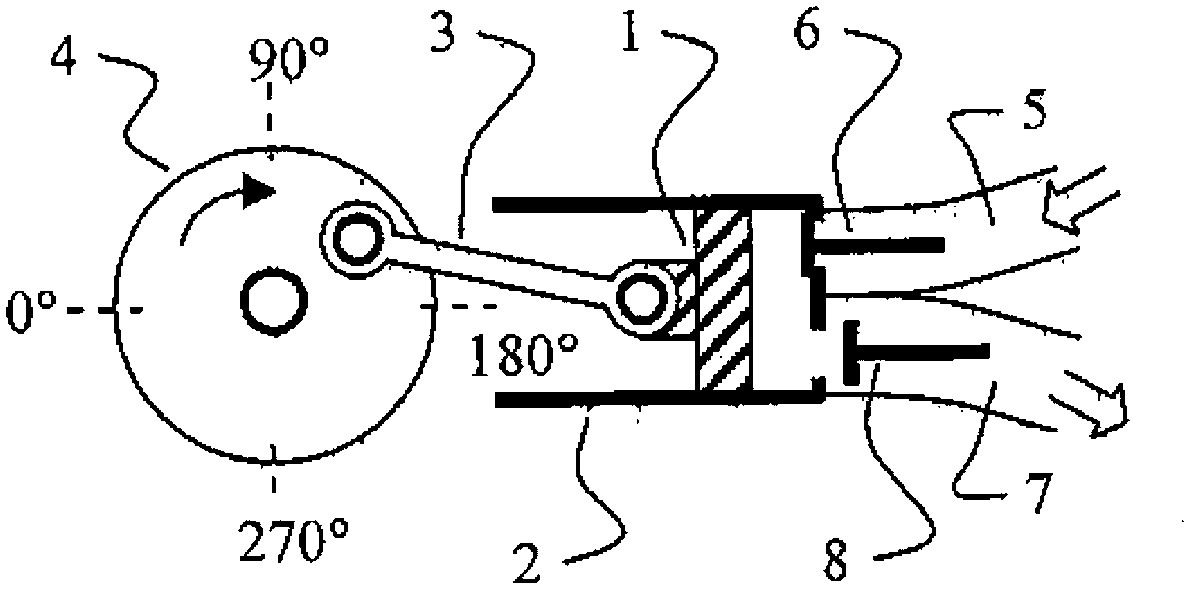

[0024] figure 1 A known construction of a piston compressor is shown in which a piston 1 reciprocates inside a compression cylinder 2 . In this embodiment, said piston is driven by a crankshaft or similar via a connecting rod 3 through a rotating wheel 4 . The input gas enters the cylinder from the suction pipe 5 during the opening of the input valve 6 during the suction phase, ie during the movement of the piston away from the valve creating a vacuum inside the cylinder. During the compression phase, ie during the movement of the piston towards the valve, the gas is compressed and finally discharged into the pressure pipe 7 (with the discharge valve 8 open). The angular value (0°...270°) around the wheel 4 indicates the position mark of the attachment point of the connecting rod to the wheel and indicates the mechanical position of the piston during one cycle of operation rotation.

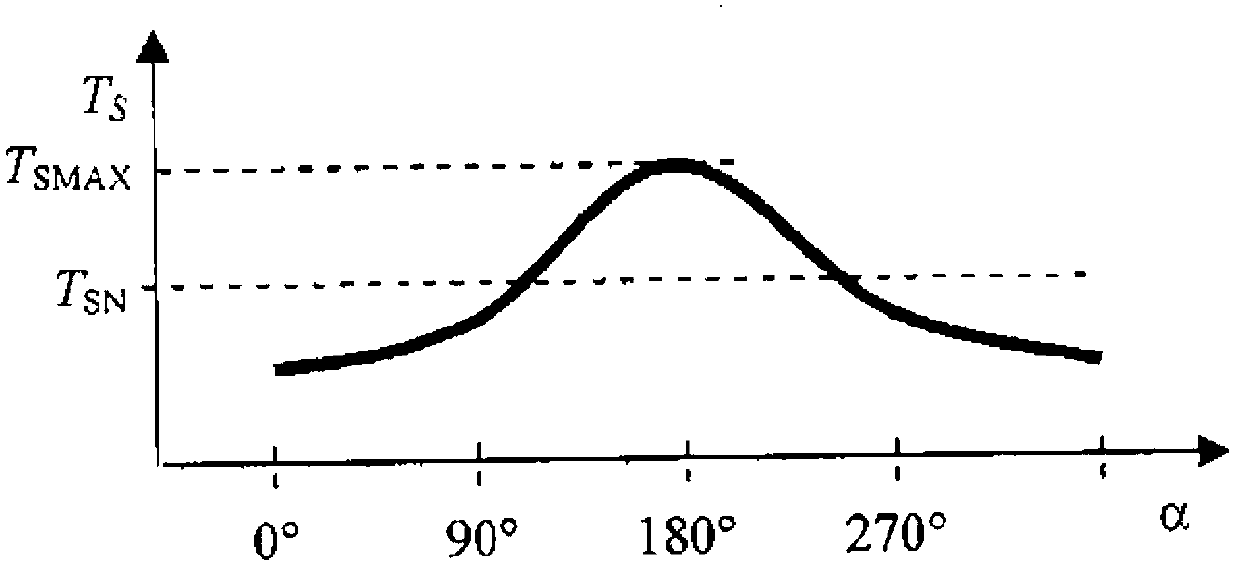

[0025] figure 2 shows drive wheel 4 ( figure 1 ) of the shaft or the corresponding torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com