Connector installed on water tank seat of coffee machine

A technology of coffee machine, water tank, applied in the direction of beverage preparation device, home appliance, application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

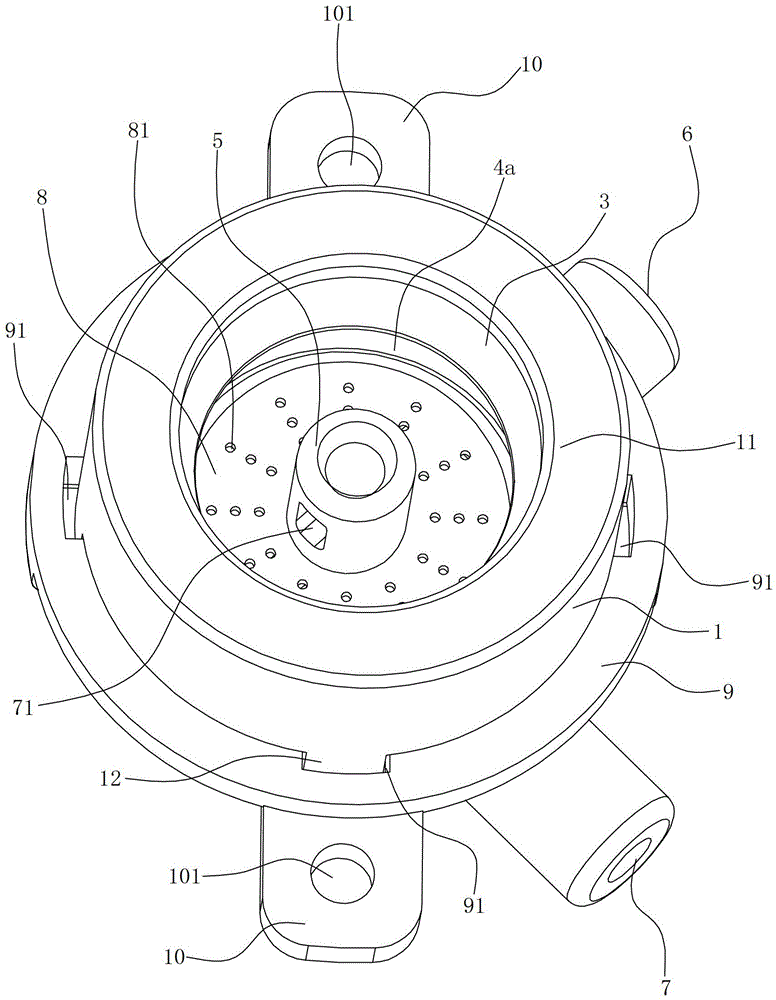

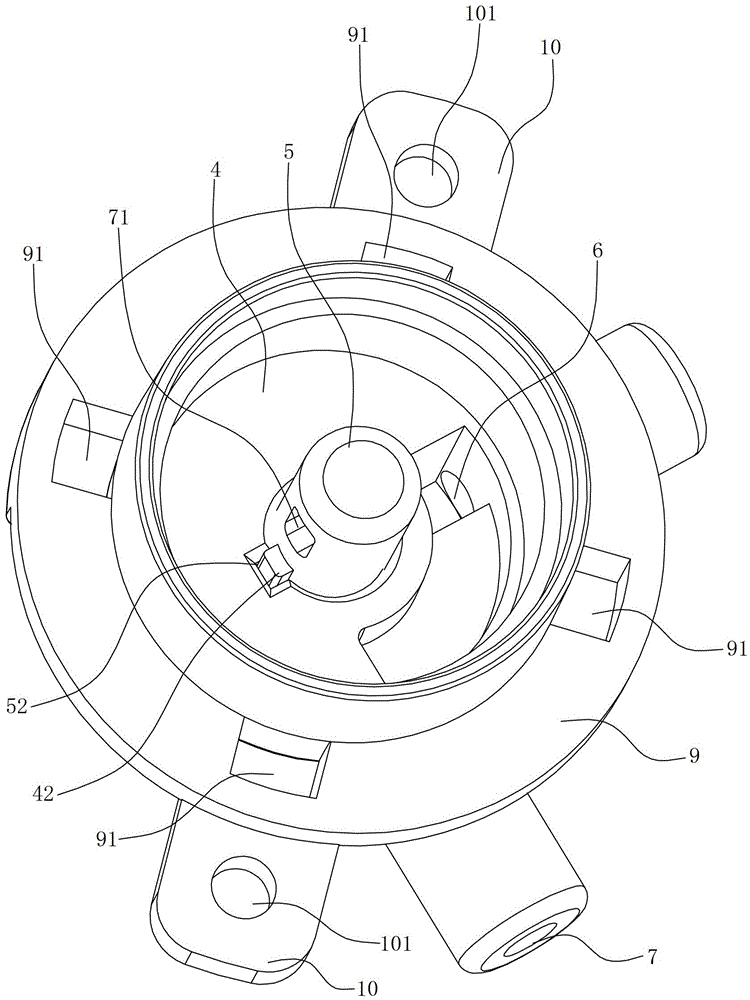

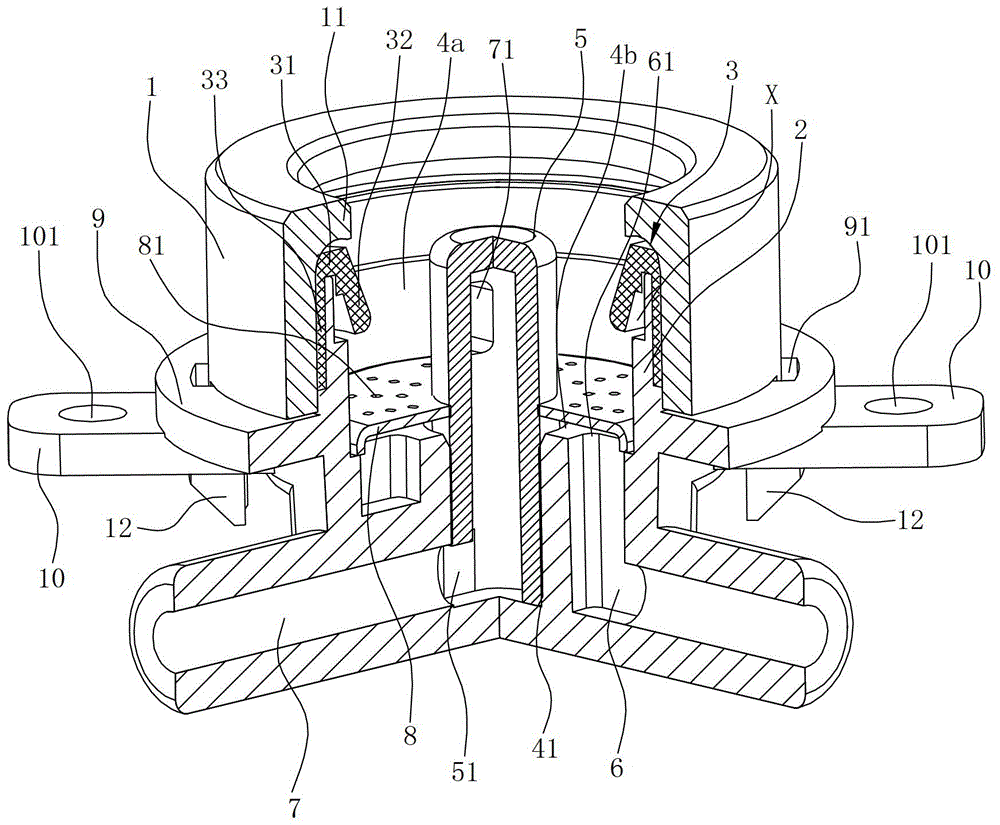

[0025] like Figure 1~4 Shown is a preferred embodiment of the present invention.

[0026] A joint installed on the water tank seat of the coffee machine, including a joint body for connecting with the water outlet of the water tank, the water tank is not shown in the drawings. The joint body in this embodiment includes a sleeve 1, a socket 2 and a sealing ring 3. The cross section of the sleeve 1 is roughly circular, and the upper part of the inner peripheral wall of the sleeve 1 has an annular stop extending inward. 11. The lower end surface of the sleeve 1 has four elastic clips 12 extending downward and arranged at intervals.

[0027]The shape of the connector 2 matches the sleeve 1 and can be inserted into the sleeve 1 . The connector 2 has mounting parts 10 extending outward on both sides, and mounting holes 101 are opened on the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com