Lathe ultrasonic metal surface machining technology

A processing technology and metal surface technology, applied in the field of ultrasonic processing, can solve the problem of not giving process parameters, and achieve the best effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

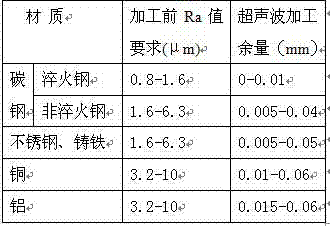

[0019] The lathe ultrasonic metal surface processing technology of the present invention can directly adopt the ultrasonic tool applied to the lathe, and can also adopt the ultrasonic metal surface processing device applied to the lathe (such as "a kind of numerical control ultrasonic processing device for ordinary lathes" disclosed in CN101503755 ), clearly stipulates the ultrasonic processing process and the processing parameters of different materials, including the following steps: (1) Install the ultrasonic tool applied on the lathe on the tool holder of the lathe, or install the ultrasonic metal applied on the lathe The surface processing device is installed on the bed of the lathe;

[0020] (2) Connect the cable between the ultrasonic tool and the external ultrasonic generator;

[0021] (3) Clamp the workpiece on the spindle of the lathe, the clamping method is the same as the clamping method for turning on the lathe (the clamping method of the workpiece on the lathe ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com