7.63m coke oven rising pipe water sealing method

A manufacturing method and technology for water sealing cover, which are applied in the field of water sealing cover for 7.63m coke oven riser pipe, can solve the problems of affecting the air tightness of the contact surface, high production cost, unreasonable and other problems, so as to reduce the production cost and improve the sealing performance. Good, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

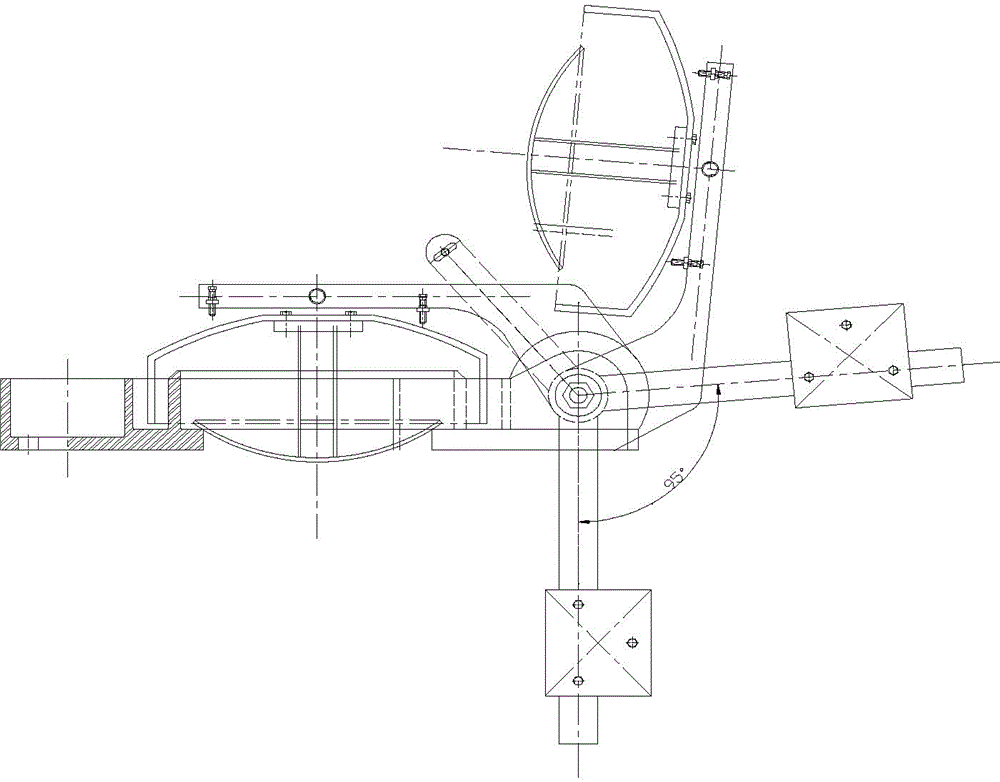

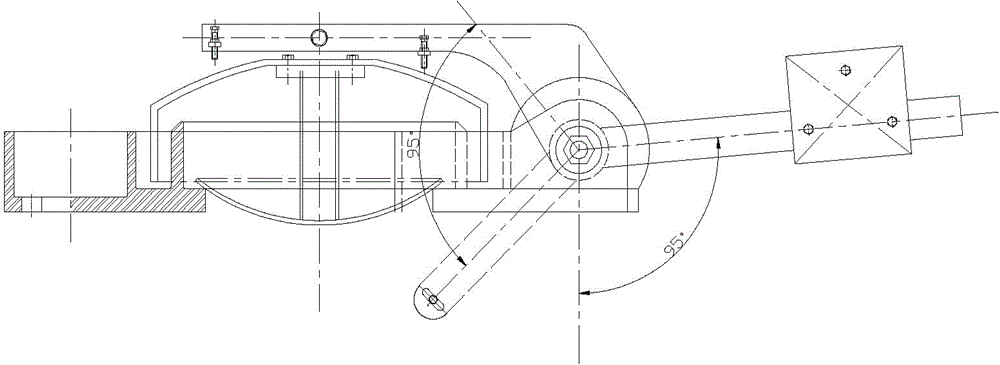

[0039] see now figure 1 , figure 1 It is a schematic diagram of the water seal structure of the embodiment of the present invention, figure 2 It is a schematic diagram of the opening angle of the water sealing handle of the embodiment of the present invention.

[0040] The manufacturing method of the 7.63m coke oven riser water sealing cover of the present invention is characterized in that it comprises the following steps:

[0041] a. The production of the water-sealed top cover includes the following steps:

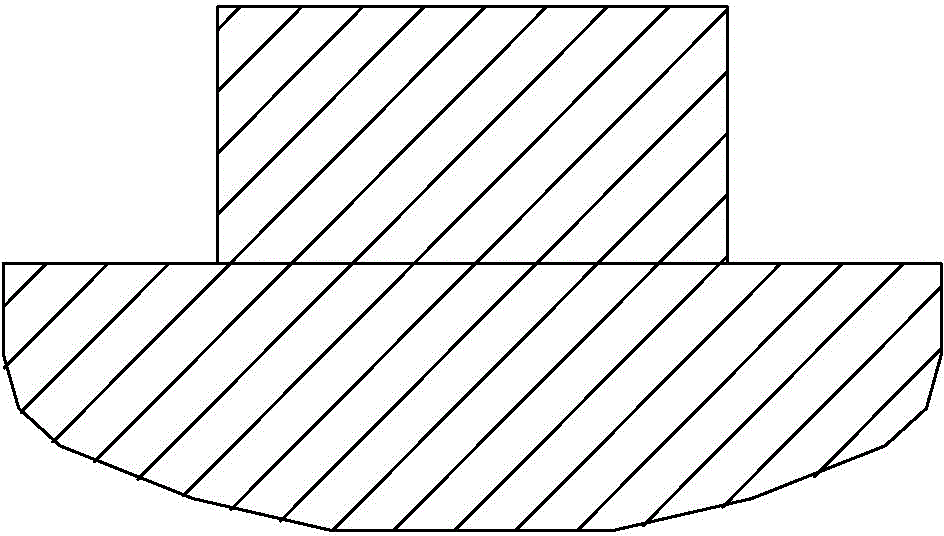

[0042] image 3 It is a schematic diagram of the upper mold of the water-sealed top cover pressing mold according to the embodiment of the present invention, Figure 4 It is a schematic diagram of the lower mold of the water-sealed top cover pressing mold according to the embodiment of the present invention.

[0043] (1) Manufacture of a special mold for the top cover of the water seal

[0044] The top cover of the water seal cover is pressed and formed by a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com