Assembly and disassembly tool for clamping-pressing type mechanical connector

A technology for mechanical connectors and disassembly tools, applied in the directions of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of hindering disassembly methods, high sealing pressure, and limiting the wide application of press-type mechanical connectors, and achieves the connection process. Safe and stable, to achieve the effect of non-welding connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the present invention in more detail with examples in conjunction with the accompanying drawings:

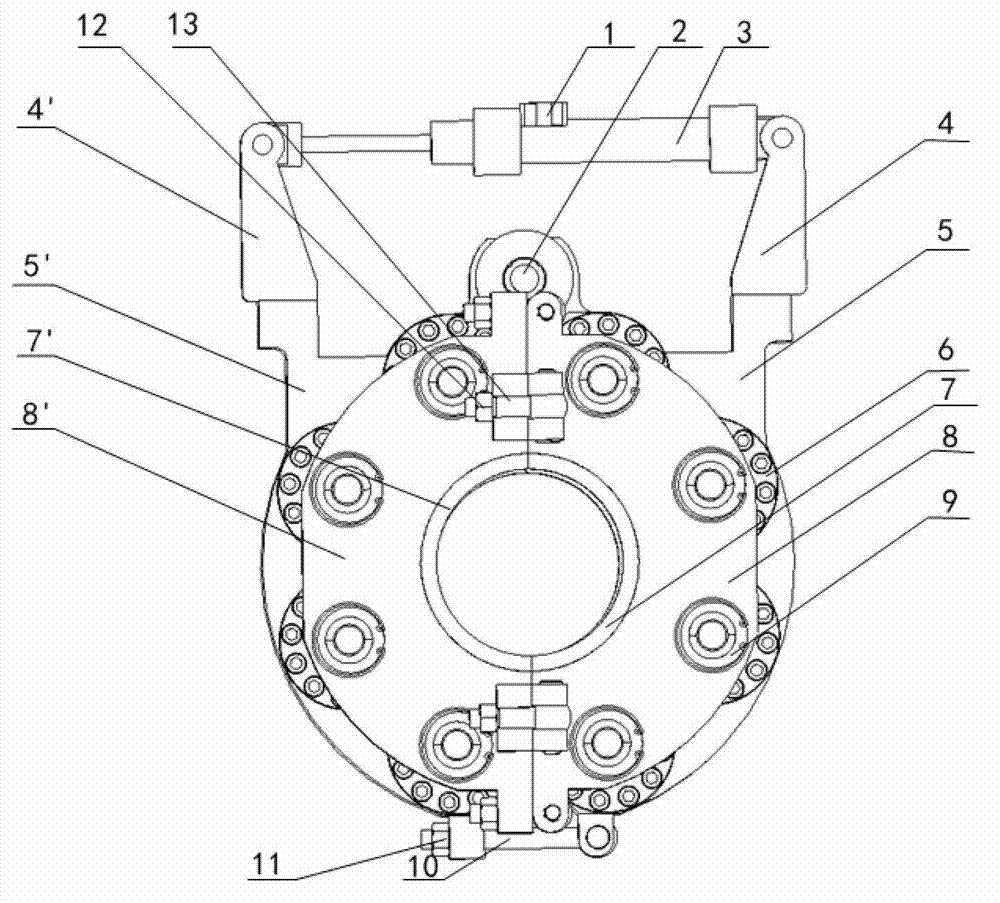

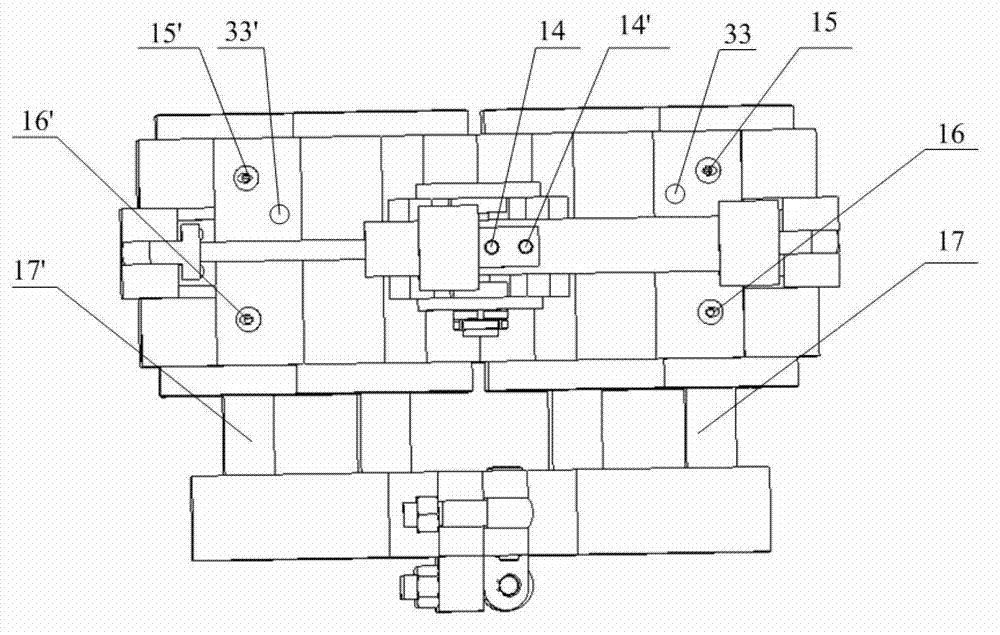

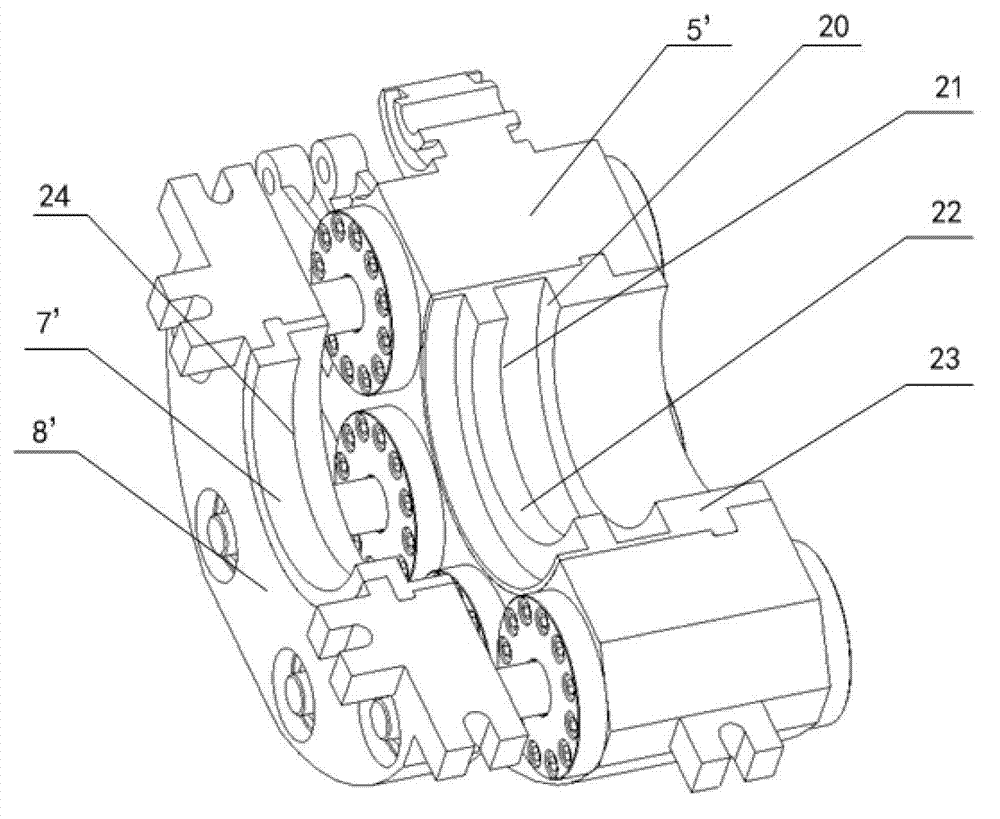

[0026] Combine figure 1 -Figure 3, this special tool for compression mechanical connectors includes a hydraulic cylinder loading mechanism for axial loading and disassembly of the compression mechanical connector and a hydraulic cylinder opening and closing mechanism that controls the loading mechanism to open and close on the axial vertical plane . in figure 1 with figure 2 The meaning of the symbol in the middle is: 1 balance valve, 2 connecting hinge, 3 opening and closing hydraulic cylinder, 4 right opening and closing hydraulic cylinder bracket, 5 right hydraulic cylinder base, 6 right hydraulic cylinder base front cover, 7 right jaw gasket, 8 right jaw, 9 hydraulic cylinder snap ring, 10 hydraulic cylinder base lock pin, 11 base lock pin nut, 8'left jaw, 7'left jaw gasket, 5'left hydraulic cylinder base, 4'left opening and closing Hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com