Automatic pull-and-push box mechanism for fixed type rubbish compression device

A garbage compression and fixed technology, applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of insecurity, troublesome operation, increased cost, etc., to improve safety, reduce docking time, and improve compression efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

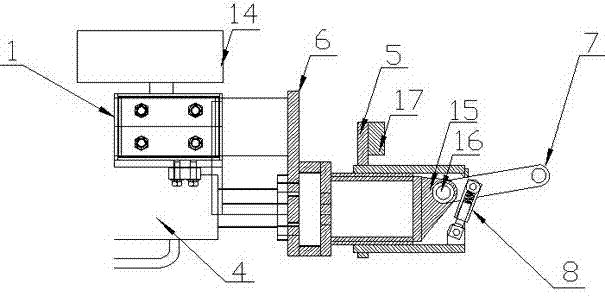

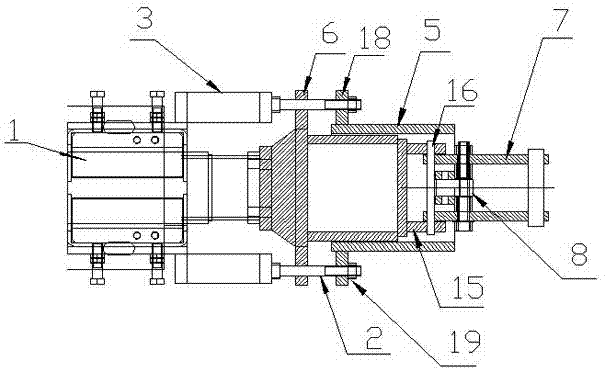

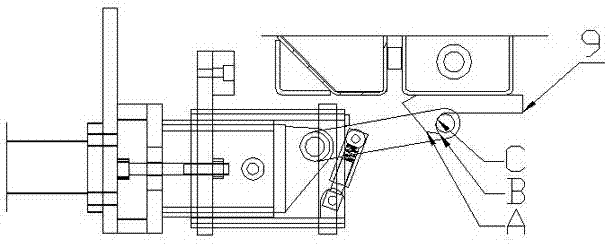

[0010] Such as figure 1 The shown automatic push-pull box mechanism of a fixed garbage compression equipment mainly includes a compression host 14, a guide rail bracket 1, a guide bolt 2, a guide bolt limit support 3, a push-pull oil cylinder 4, a movable push seat 5 with a front and rear through a rectangular parallelepiped, a fixed Push seat 6, hook 7 and spring support 8, guide rail support 1 and push-pull oil cylinder 4 are fixed on the compression host, the telescopic rod of push-pull oil cylinder 4 is fixedly connected with fixed push seat 6, and the front end of fixed push seat 6 is provided with bracket ear plate 15, Bracket ear plate 15 links to each other with hook 7 by bearing pin 16; The outer rear end of described movable push seat 6 is fixed with bumper 17, and the rear port of the cuboid of movable push seat 5 is provided with outward flanging 18 around, outward flanging 18 is provided with through hole, and fixed push seat 6 is provided with the through hole co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com