Water heating pipe support frame of drum washing machine

A drum washing machine, water heating technology, applied in the direction of pipe brackets, other washing machines, washing devices, etc., can solve the problems of water heating pipes using a lot of materials, fire and smoke, high price, and achieve the effect of efficient and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

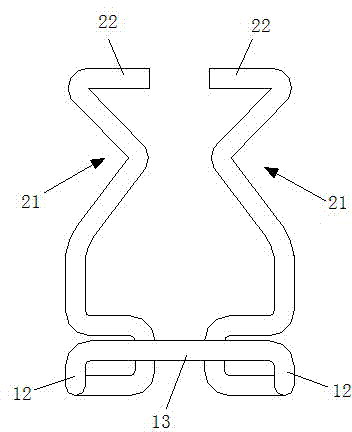

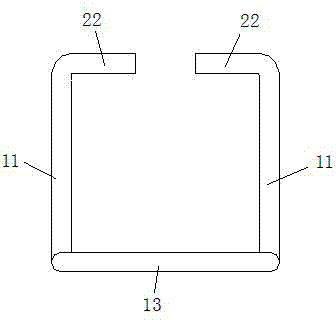

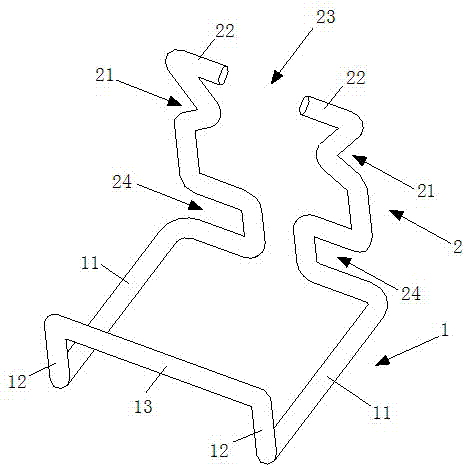

[0015] Such as Figure 1-3 Shown is a drum washing machine water heating tube bracket, the water heating tube bracket includes a positioning part 1 for plugging and fitting with the outer tub and a supporting part 2 for supporting the water heating tube.

[0016] Further, the positioning part 1 includes two straight rods 11 arranged in parallel in the horizontal direction, one end of the two straight rods 11 rises upwards and is provided with two vertical rods 12, the two vertical rods 12 are connected by a cross bar 13, and the other ends of the two straight rods 11 It is connected with the support part 2; when in use, insert the two straight rods 11 into the chute of the outer tub, and at the same time, the two vertical rods 12 and the horizontal rods 13 are equivalent to a flanging design, when the water heating tube bracket is fixed to the outer tub, this The flanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com