Oil level detecting device for compressor

An oil level detection and compressor technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve problems such as high cost, hindering compressors, difficult to apply and install hermetic compressors to detect compressor oil level, etc. Achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

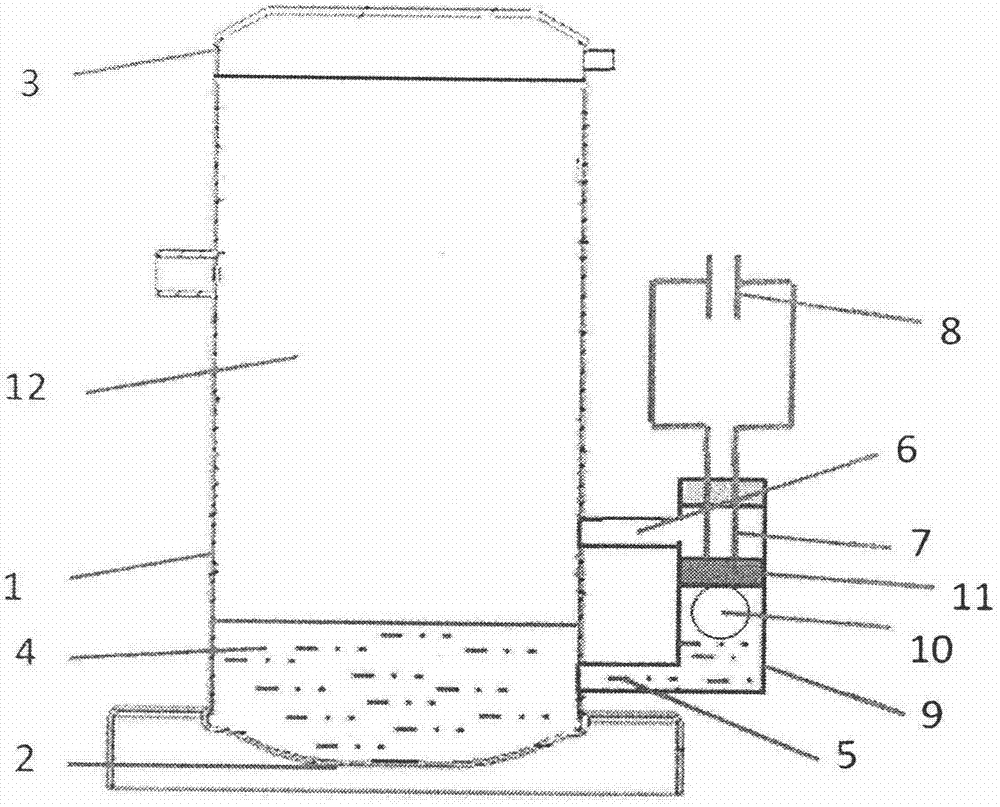

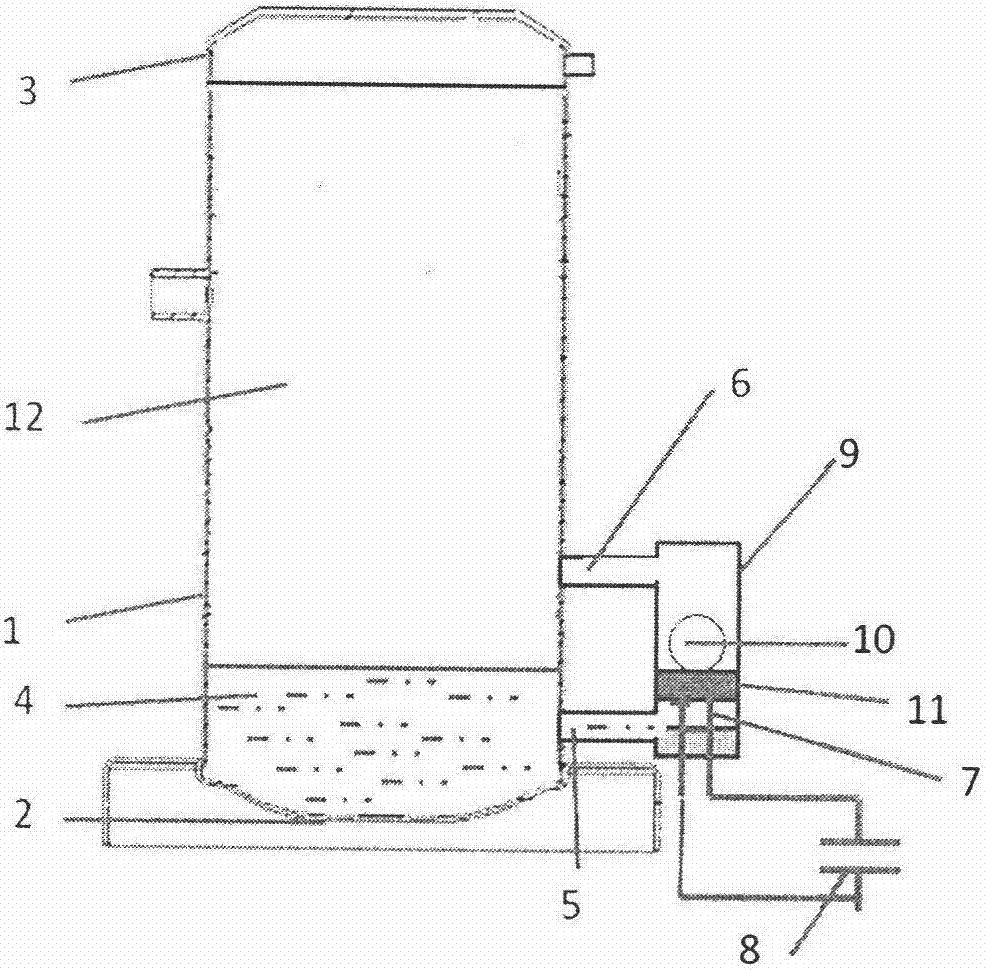

[0021] as attached figure 1 As shown, an oil level detection device for a compressor includes a housing 1, a bottom cover 2, a top cover 3, a compressor oil pool 4, a first communication pipe 5, a second communication pipe 6, a terminal 7, Power supply device 8, cylinder body 9, floating element 10, conductive partition 11, and cavity 12 inside the compressor that does not contain an oil pool.

[0022] The cylinder body 9 contains a conductive partition 11 and a floating element 10. The cylinder body 9 is provided with two communication pipes to form a connector, one end of which communicates with the compressor oil pool 4, and the other end communicates with the compressor cavity 12. The component 10 needs to float on the compressor refrigerating oil because it needs to detect the change of the internal oil level of the compressor, so the density of the floating component 10 itself needs to be lower than the density of the compressor refrigerating oil, and the conductive part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com