Fracturing truck large pump bi-directional self-adaptation shock absorber

An adaptive, fracturing vehicle technology, applied to pump components, machines/engines, variable capacity pump components, etc., can solve problems such as poor vibration reduction effect and untargeted low-frequency vibration of fracturing vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

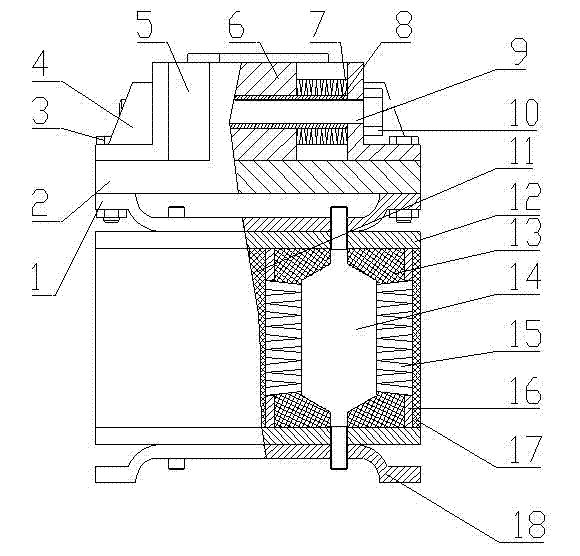

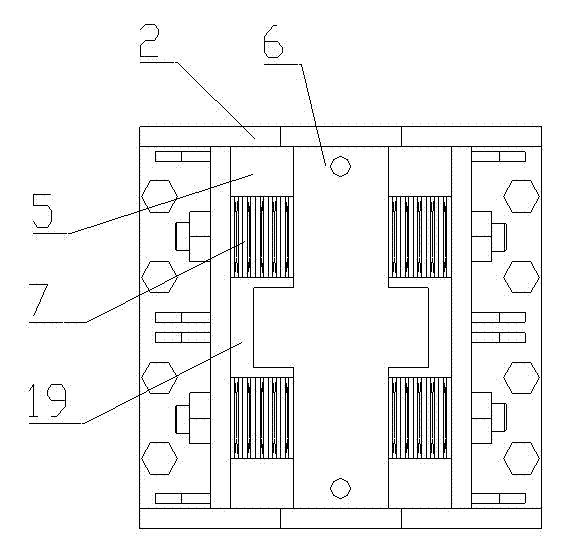

[0014] Attached below figure 1 and 2 Specific embodiments of the present invention will be further described.

[0015] see figure 1 and figure 2 First, put the cross-shaped rubber partition 11 in the box body 17, then align the bolt holes on the longitudinal vibration-damping base 18 and the load-bearing plate 12, and put the longitudinal vibration-damping disc spring 15 on the longitudinal disc spring bracket 14. The shock-absorbing disc spring sleeve 16 is mounted on both ends of the longitudinal vibration-damping disc spring 15, and the longitudinal vibration-damping rubber 13 is embedded in the longitudinal disc spring sleeve 16, and the assembled longitudinal vibration-damping device is respectively put into a cross-shaped rubber partition 11 to isolate the In the space, the upper end of the longitudinal disc spring bracket 14 passes through the load-bearing plate 12 and the connecting plate 1, and the lower end passes through the longitudinal damping base 18, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com