Transducer with large-size flange

A technology of flanges and horns, which is applied in the direction of fluid using vibration, can solve the problems of ultrasonic vibration energy loss, machine tool damage, machine tool spindle impact, etc., and achieve the effect of ensuring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

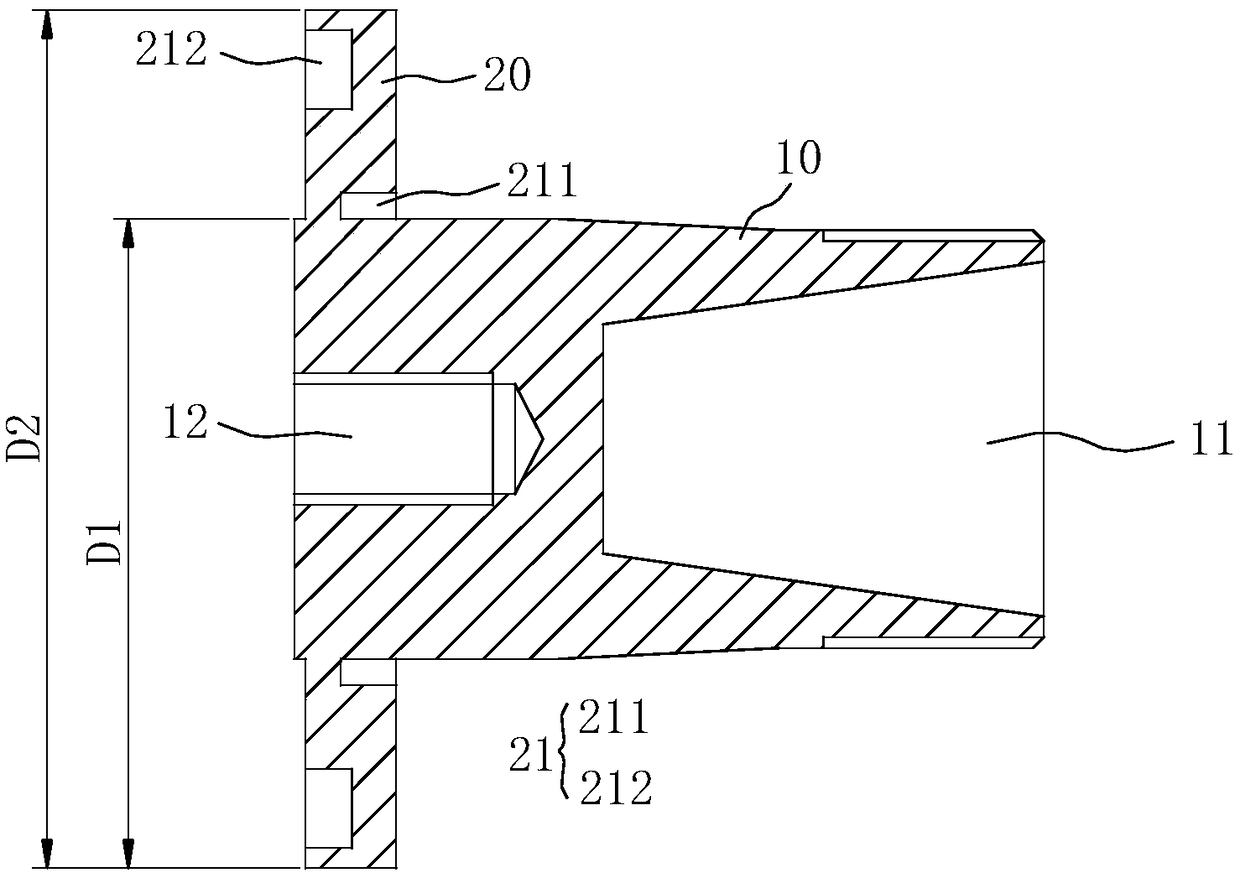

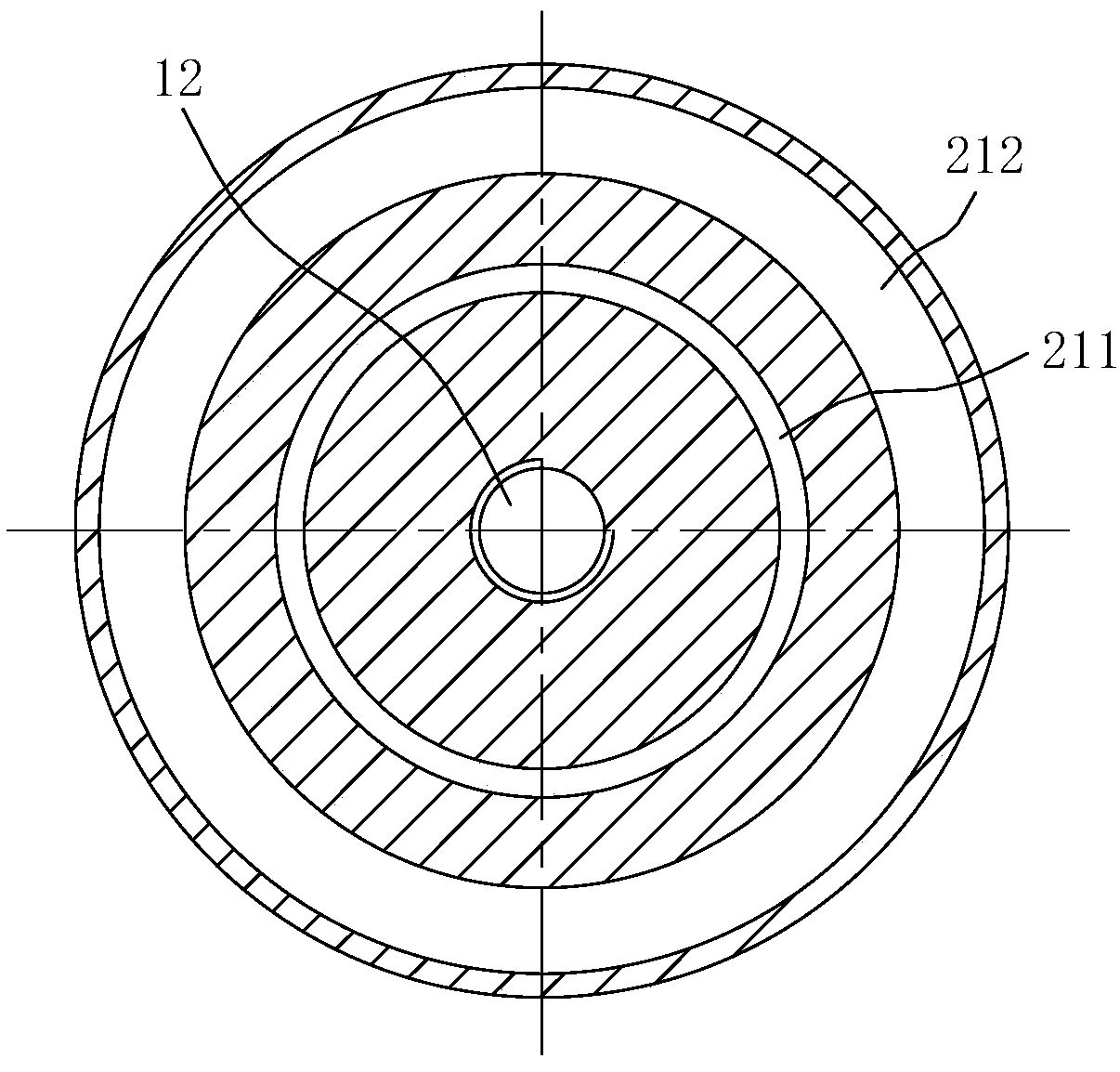

[0034] Such as figure 1 and figure 2 As shown, the horn in this embodiment includes a horn body 10 and a flange 20 integrally formed on the outer periphery of the horn body 10, and the front end of the horn body 10 is used for installing processing tools, so The outer periphery of the flange 20 is used to connect with the body of the ultrasonic processing device; in order to reduce the loss of ultrasonic vibration energy, a vibration-damping structure 21 is provided on the flange 20, and the vibration-damping structure 21 can reduce the ultrasonic vibration from the variable The rod body 10 transmits to the body of the ultrasonic processing device to ensure that the ultrasonic vibration energy is effectively transmitted to the processing tool, and then to the processed material through the processing tool, so as to improve the ultrasonic processing efficiency of the processing tool.

[0035] Taking the ultrasonic tool holder as an example, when the ultrasonic tool holder ado...

Embodiment 2

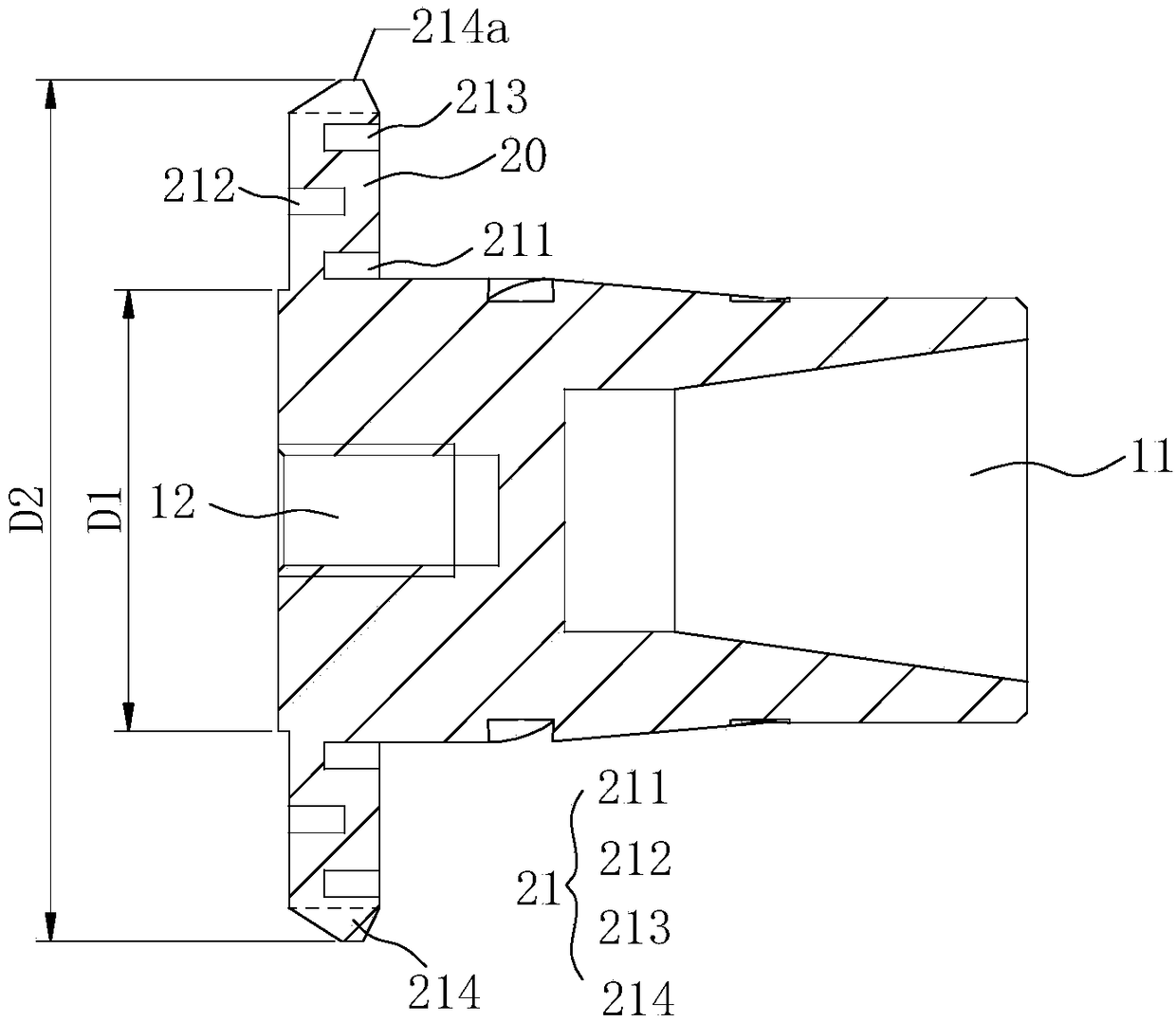

[0045] Please refer to the attached image 3 and Figure 4 As shown, the difference between the horn in this embodiment and the first embodiment is that, in addition to the first annular groove 211 and the second annular groove 212, the damping structure 21 also includes a The third annular groove 213 on the front face is formed with the center of the front end face of the flange 20 as the center, and the diameter of the third annular groove 213 is larger than the diameter of the second annular groove 212 .

[0046] Exemplarily, in this embodiment, the outer diameter of the horn body 10 is 20 mm, the outer diameter of the flange 20 is 39 mm, and the larger flange 20 can ensure the overall rigidity of the horn, and compared to As for the first embodiment, by providing more grooves on the flange 20 , it is possible to further reduce the transmission of ultrasonic vibrations to the body of the ultrasonic processing device through the flange.

[0047] Please continue to see atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com