Leveling method suitable for compound level gauge

A composite level and level measurement technology, applied in the field of measurement, can solve the problems of low measurement efficiency and reliability, and difficulty in ensuring measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

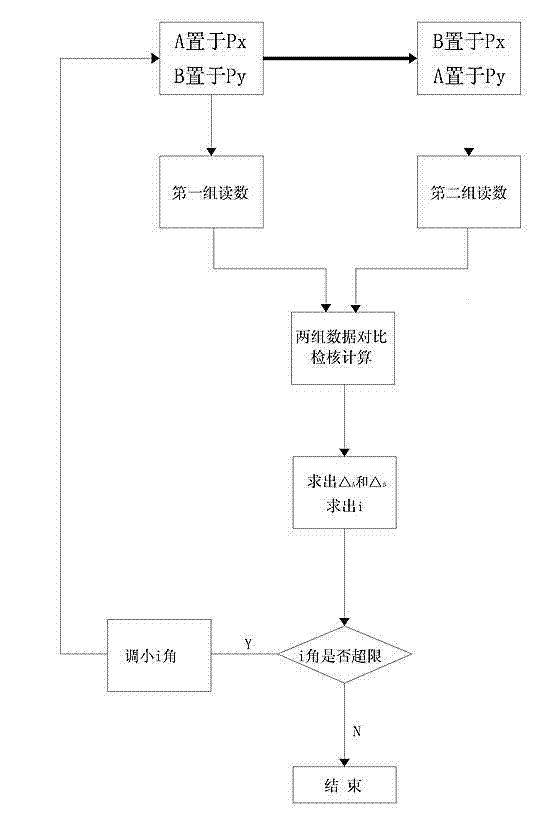

[0068] a. Determination and calibration of the composite level before testing i horn

[0069] works like image 3 shown.

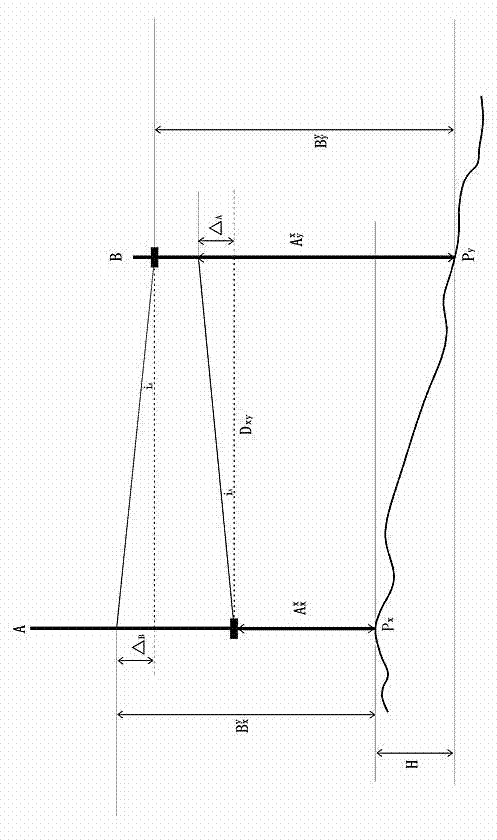

[0070] a1. If figure 1 Shown: First select two fixed points on a flat lot with , place the two composite levels A and B in with , that is, the composite level A is placed in , the compound level B is placed in , and then leveling synchronously, aiming at each other, observing and reading the local scale, and observing and reading the opposite scale, that is, measuring the fixed point as in the prior art with The first set of opponent height and own height data.

[0071] Composite level A obtained with height difference between two points It can be expressed as (Note: When calculating the height difference, the data of the other side is subtracted from the data of the other side, the same below):

[0072]

[0073] In the formula:

[0074] For composite level A i Angular error ( i When the angle is upward, it is taken as a p...

Embodiment 2

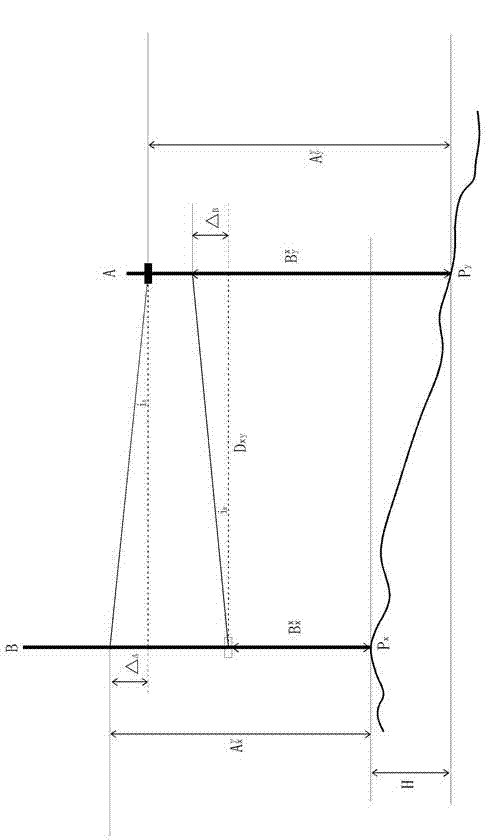

[0149] As a1, a2 steps of embodiment 1 carry out the calibration composite level before measuring i horn.

[0150] The difference from Example 1 is the b1 step. works like Figure 7 shown.

[0151] b1. Exchange placement measurement. Such as Figure 4 Shown: place the composite levels A and B respectively at the leveling points to be measured with , that is, the composite level A is placed in , the compound level B is placed in , and then leveling synchronously, aiming at each other, observing and reading the local scale, and observing and reading the opposite scale, that is, measuring the fixed point as in the prior art with The first set of opponent height and own height data.

[0152] Placed by composite level A on acquired with height difference between two points Can be expressed as:

[0153]

[0154] In the formula:

[0155] For composite level A i Angular error ( i When the angle is upward, it is taken as a positive value, i When the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com