Illuminator failure monitoring device

A fault monitoring and illuminator technology, which is applied to lighting devices, lamp circuit layout, light sources, etc., can solve the problems of untimely maintenance, high maintenance cost, and low work efficiency, so as to improve the degree of intelligence, timely alarm at fault points, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A lighting fault monitoring device, the power supply line provides 220V50Hz alternating current. As we all know, the AC current output by the current transformer 9 at this time i The change period is also 50Hz, such as Figure 5 , Figure 6 As shown by the dotted line, it will not be repeated here.

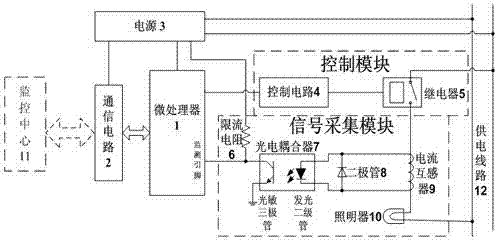

[0035] Such as figure 1 As shown, the current limiting resistor 6 is a circuit form of a pull-up resistor. When the illuminator 10 is in a normal working state, the power supply line 12 will have a current flow, and the current transformer 9 will sense and transmit an alternating current. The flow direction of the alternating current is consistent with the When the conduction directions of the light emitting diodes in the photocoupler 7 are consistent, the light emitting diodes in the photocoupler 7 will be driven to emit light and irradiate the base of the phototransistor of the photocoupler 7, and the base will be in a conduction state after being illuminated. Make th...

Embodiment 2

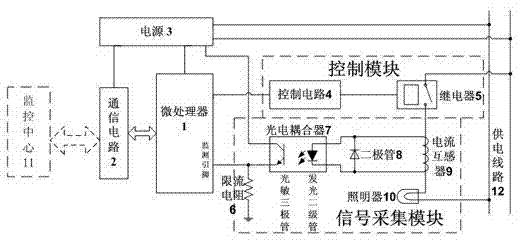

[0038] A lighting fault monitoring device, the power supply line provides 220V50Hz alternating current. As we all know, the AC current output by the current transformer 9 at this time i The change period is also 50Hz, such as Figure 6 The dotted line will not be repeated here. Such as figure 2 As shown, the current limiting resistor 6 is a circuit form of a pull-down resistor. When the illuminator 10 is in a normal working state, the power supply line 12 will have a current flow, and the current transformer 9 will sense and output an alternating current. The flow direction of the alternating current is related to the photoelectric When the conduction directions of the light-emitting diodes in the coupler 7 are consistent, the light-emitting diodes in the photocoupler 7 will be driven to emit light and irradiate the base of the phototransistor of the photocoupler 7, and the base will be in a conduction state after being illuminated, so that The level of the monitoring pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com