Food baking one-key-system control method

A control method and food technology, applied in the direction of roaster/barbecue grid, kitchen utensils, home utensils, etc., can solve the problems of troublesome control and poor baking effect, so as to save power, solve the temperature of the cavity, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

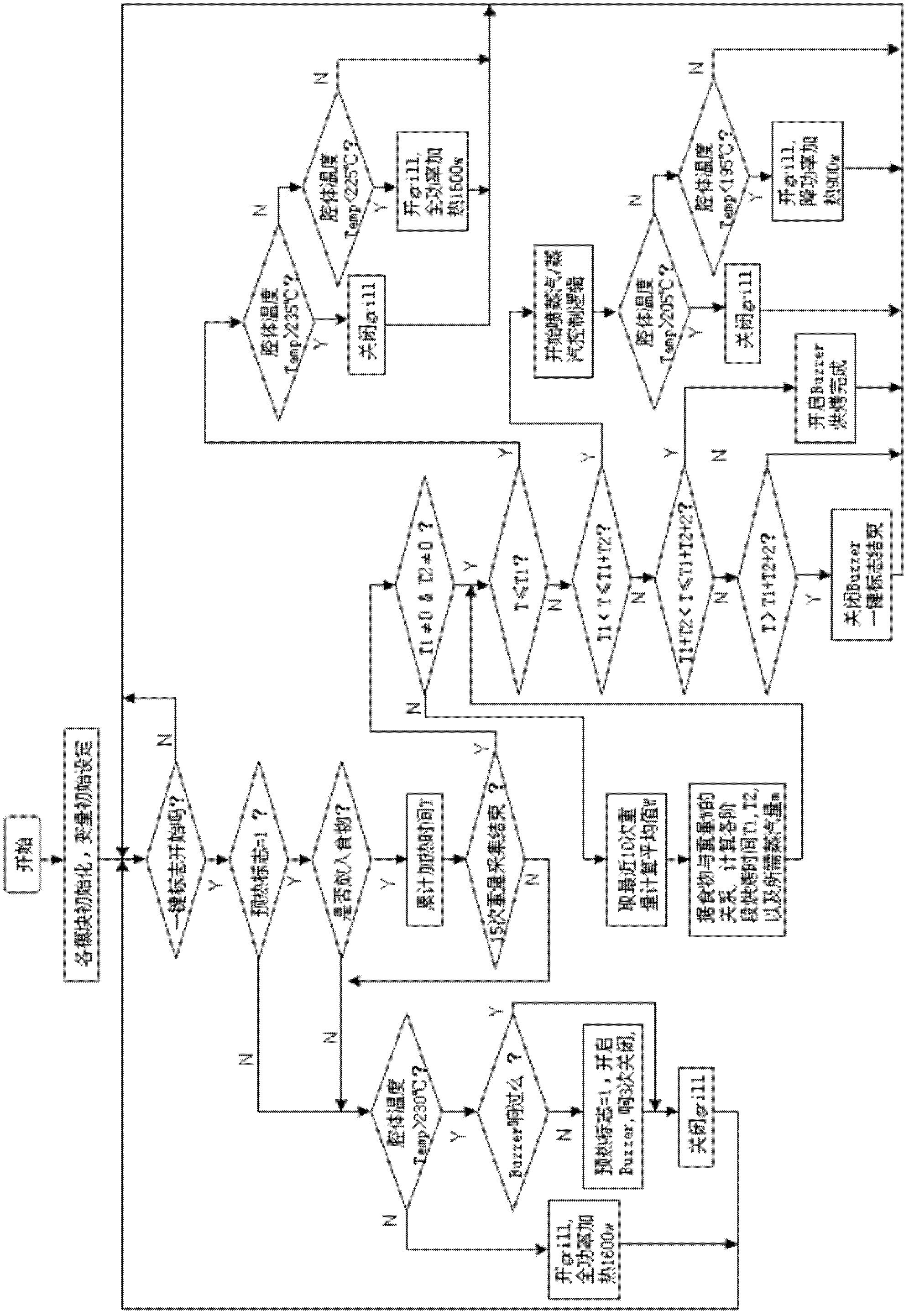

[0060] The one-button control method for food baking of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

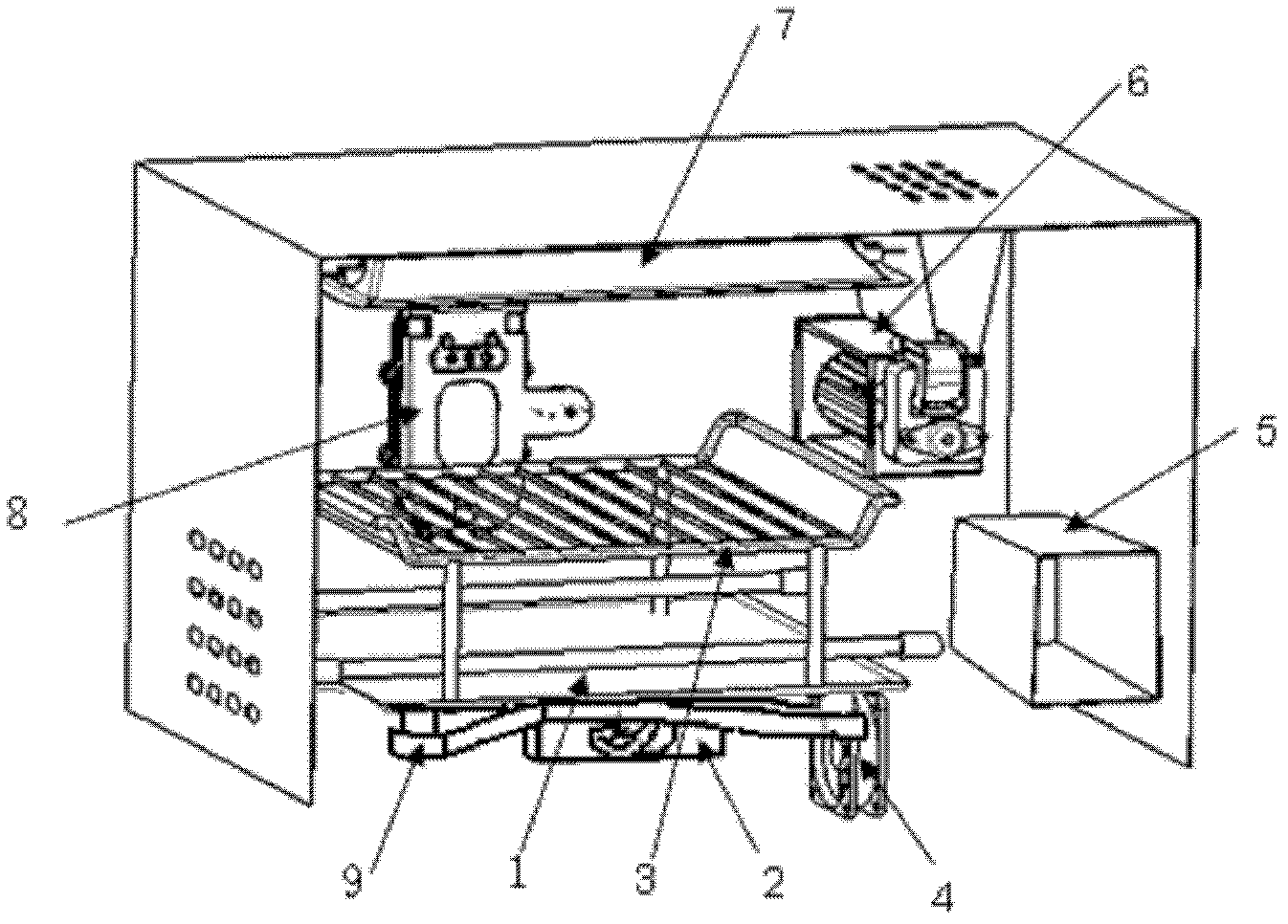

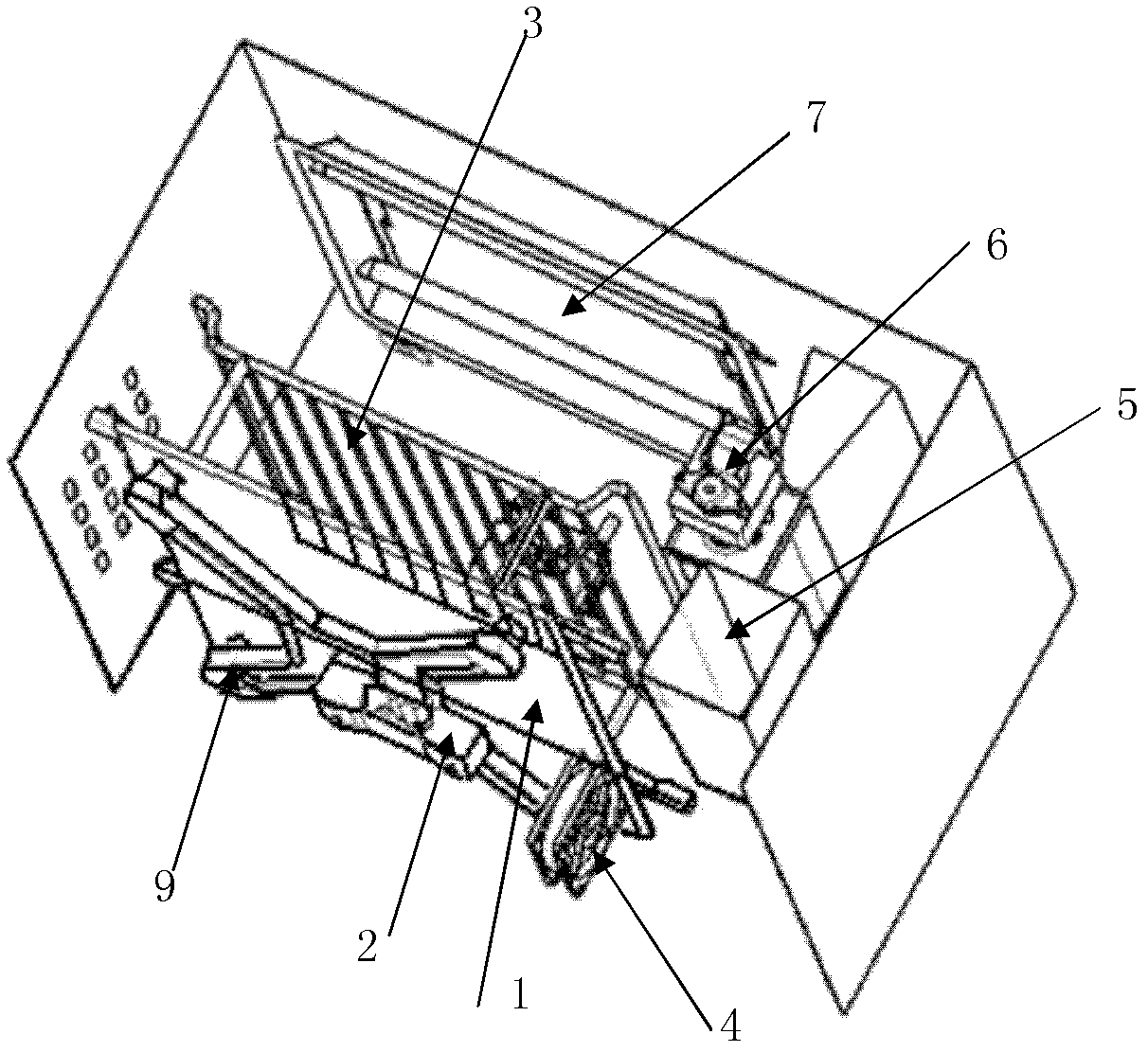

[0061] The food baking one-button control method of the present invention is used on an oven with automatic weighing, and the oven with automatic weighing is as follows: figure 1 , figure 2As shown, a tray 1 is provided in the oven cavity, a grill 3 for placing food is arranged on the tray 1, the legs of the grill 3 pass through the bottom of the tray 1, and a grill 3 is arranged on the tray 1. Fix the bracket 9 of the gravity sensor 2, the bracket 9 is elastically arranged under the tray 1, and can sense the pressure of the legs of the grill 3, and a baking tube for baking is arranged above the oven cavity 7. A steam launching device and a fan 4 for circulating hot air are also arranged in the cavity of the oven. The steam launching device includes a water tank 5 for storing water, a steam heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com