Bottle washing holder

A bottle clamp and chuck technology, which is applied in the field of bottle washing clamps, can solve the problems of dead corners, unfavorable cleaning, easy to drop bottles, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

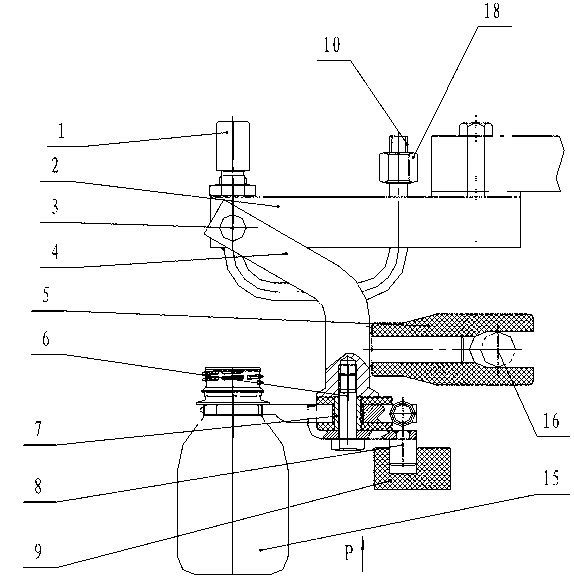

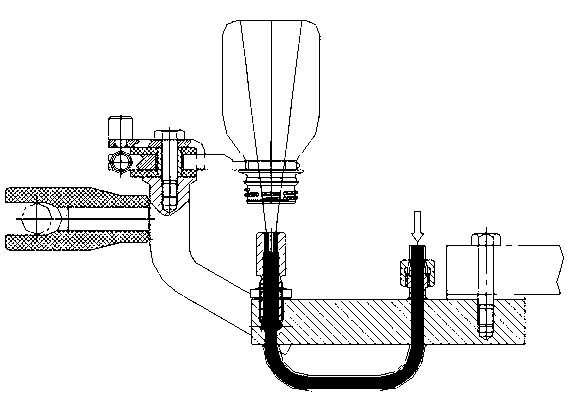

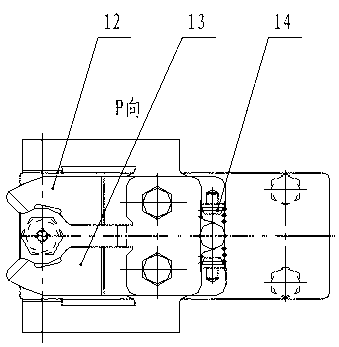

[0016] Such as Figure 1 to Figure 3 As shown, a bottle washing clip of the present invention mainly includes a nozzle 1, a support body 2, a small shaft 3, a turning frame 4, a sliding fork 5, a disinfectant liquid inlet 10 and a chuck, wherein:

[0017] One end of the overturn frame 4 is rotatably arranged on the front end of the support body 2 through the small shaft 3, and the side of the overturn frame 4 is equipped with a sliding fork 5, which is used to be installed on the guide rail and slide along the guide rail 16 during work to guide The overturn frame 4 is overturned, the chuck is installed on the other end of the overturn frame 4 by the bolt 6 and the bush 7, the nozzle 1 is installed on the upper side of the support body 2, and the nozzle 1 is connected with the disinfectant installed on the other side of the support body 2 through the flushing medium channel. The liquid inlet 10 is connected, and a guide device is provided on the reversing frame 4 to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com