Mould

A mold and master template technology, which is applied in the field of molds, can solve the problems of easy jamming of inclined guide posts and slider seats, and easy warpage of mother templates, so as to reduce the probability of jamming, avoid warpage, and increase edge width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

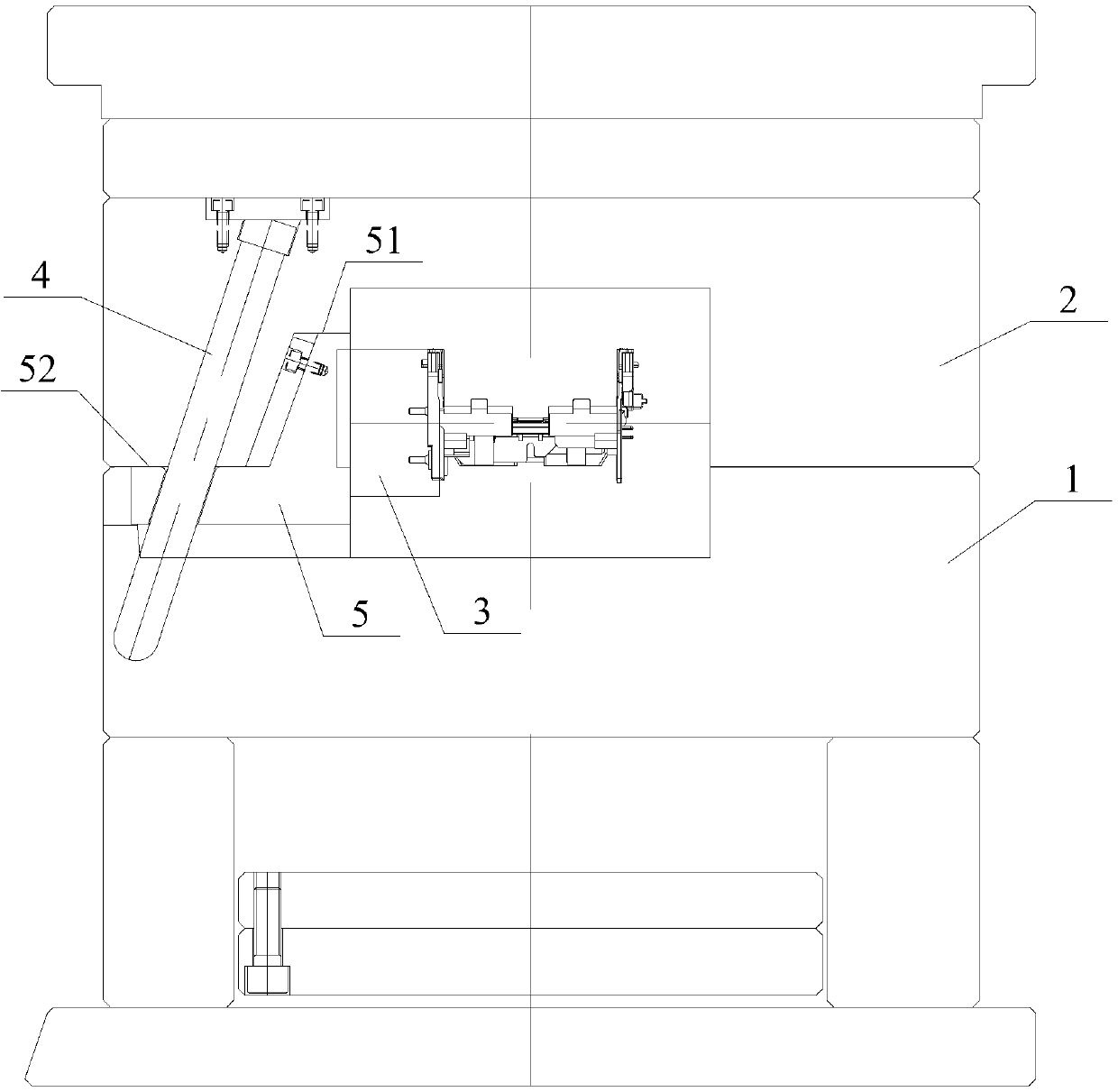

[0009] like figure 1 As shown, the mold provided by the present invention includes male and female templates 1, 2 and a slider 3 between them, the female template 2 is fixed with an oblique guide column 4, the outside of the slider 3 is against a slider seat 5, and the oblique The guide post 4 is inserted in the slider seat 5, the slider seat 5 is stepped, including an upper step surface 51 and a lower step surface 52, the width of the lower step surface 52 is greater than the width of the upper step surface 51, and the inclined guide post 4 is inserted in the lower step surface. on the step surface 52 .

[0010] The traditional inclined guide post 4 is inserted into the upper step surface 51 of the slider seat 5, resulting in the entire slider seat 5 being enlarged. In the present invention, the inclined guide post 4 is only added on the lower step surface 52 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com