Hanging basket elevator

A hoist and hanging basket technology, applied in the direction of hoisting devices, etc., can solve the problems of hoist rope jamming, economic loss, and lower work efficiency, and achieve the effects of reducing the probability of rope jamming, reducing economic loss, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

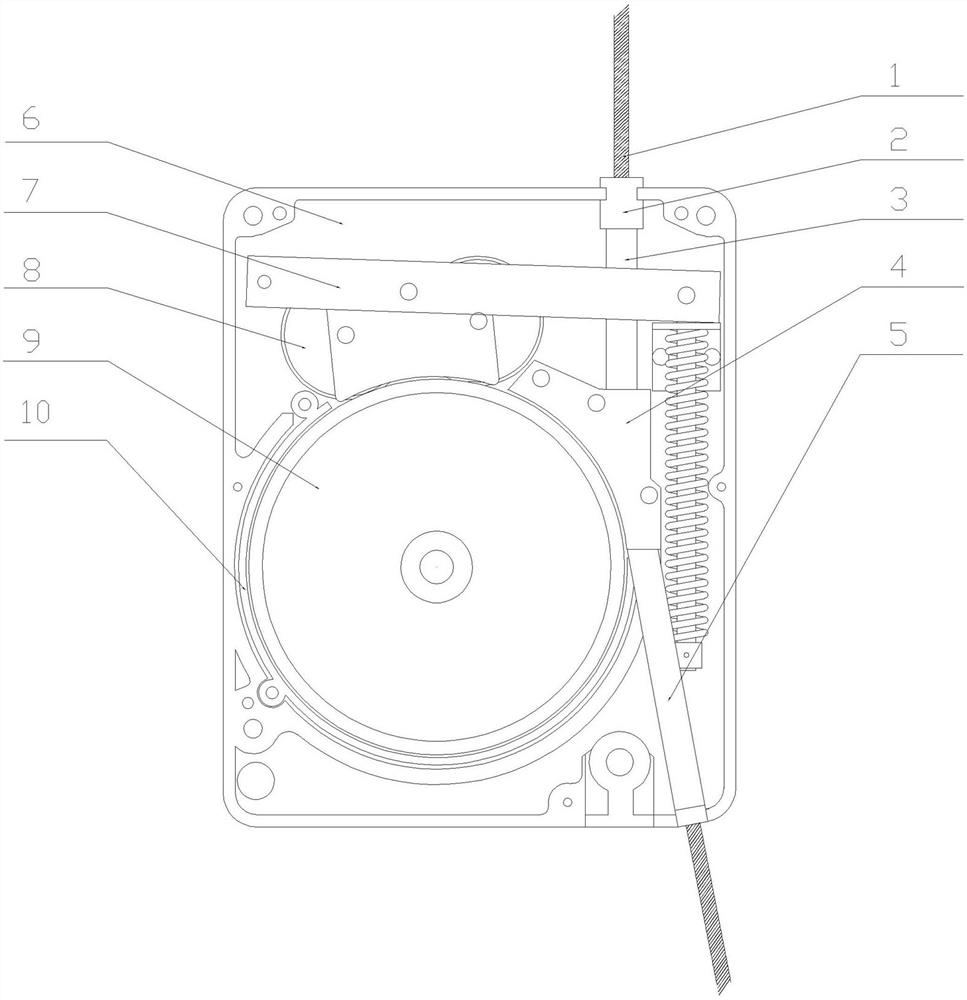

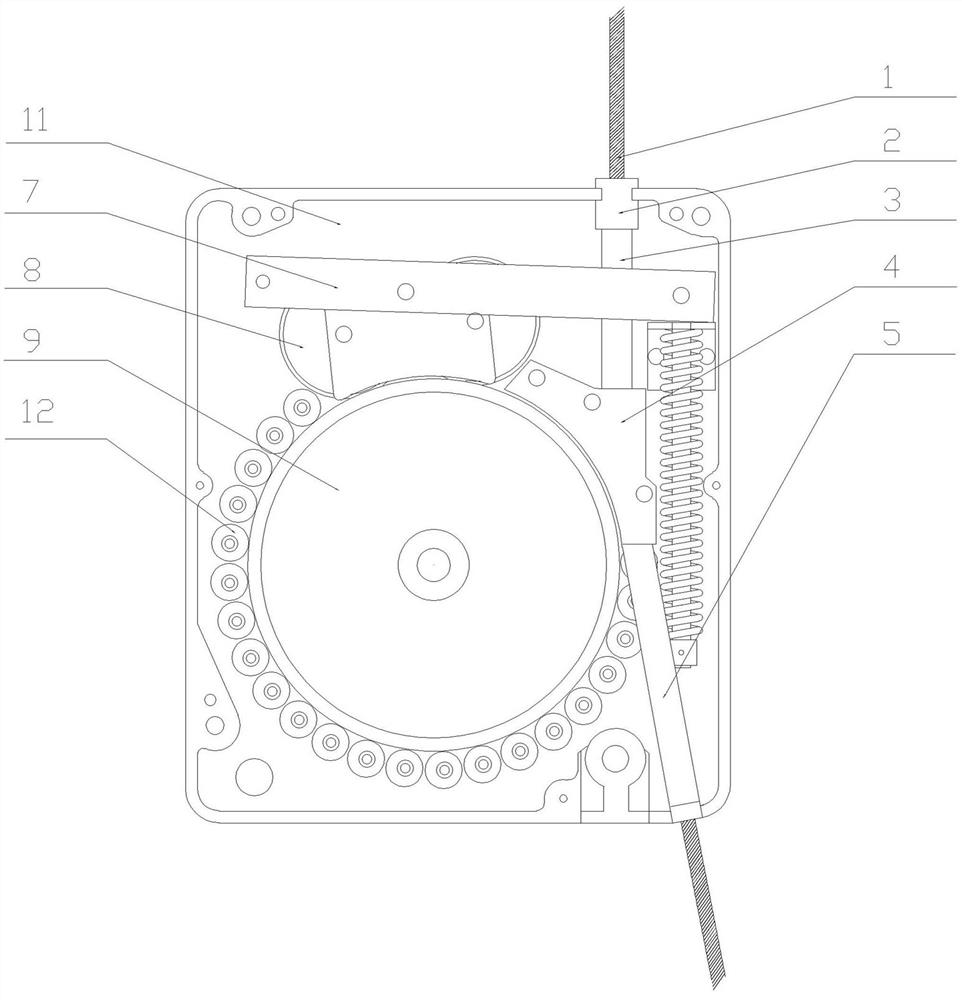

[0025] Such as figure 2 As shown, the present invention provides a hanging basket hoist, including: hoist housing 11, rope inlet pipe 3, rope splitter 4, large turntable 9, pulley block 12, rope pressing mechanism 7, and rope outlet pipe 12.

[0026] The combined connection method of each component is as follows:

[0027] Such as figure 2 As shown, the rope inlet pipe 3 of the hanging basket hoist, the rope divider 4, the large turntable 9, the rope pressing mechanism 7, and the rope exit pipe 5 keep their original positions unchanged, and the rope pressing mechanism 7 is fixed above the big turntable 9, and the The rope device 4 is fixed on the right side of the large turntable 9, and the rope inlet pipe 3 and the rope outlet pipe 5 guide the wire rope to enter and exit the hoist. The hanging basket hoist shell 11 is widened, and the steel belt 10 of the existing hoist is removed, and the outer circumference of the large turntable 9 is equipped with pulleys 12 at position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com