Machinery-washing operating arm with electrified water for electric power engineering

A technology of electrified water and working arm, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve problems such as low efficiency of manual flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

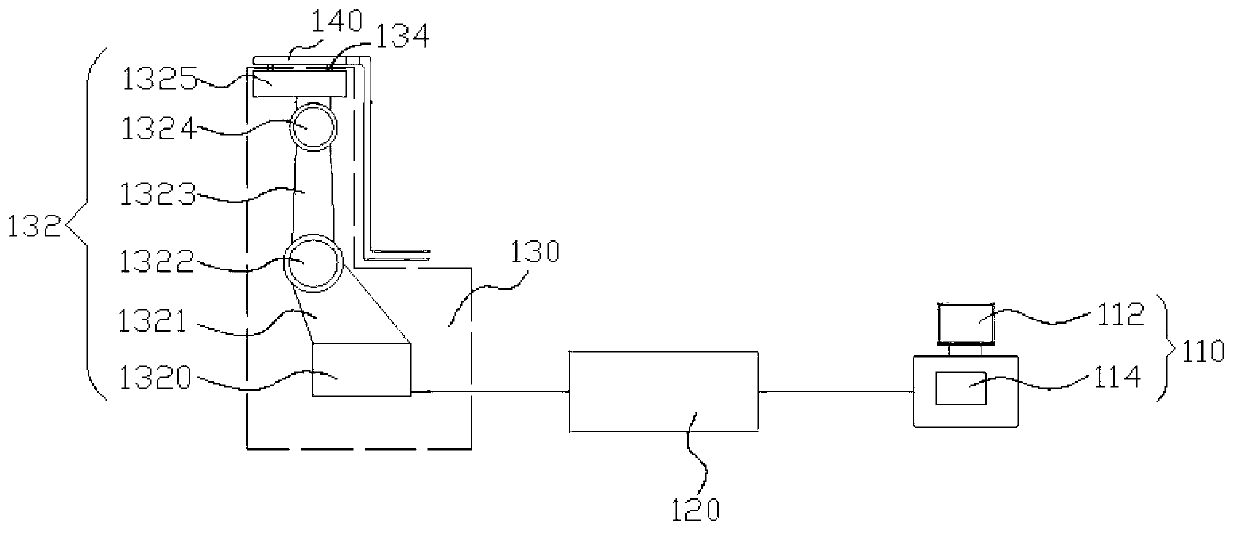

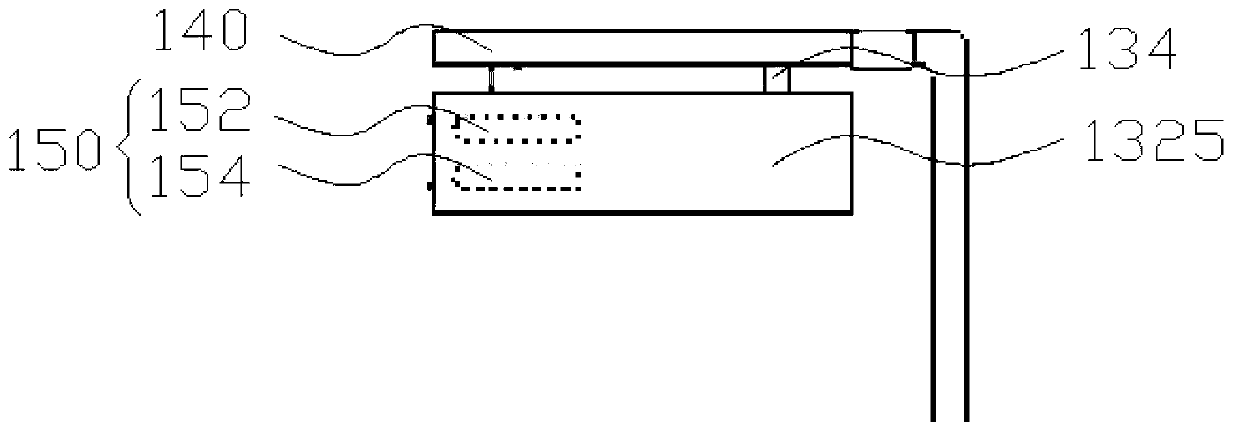

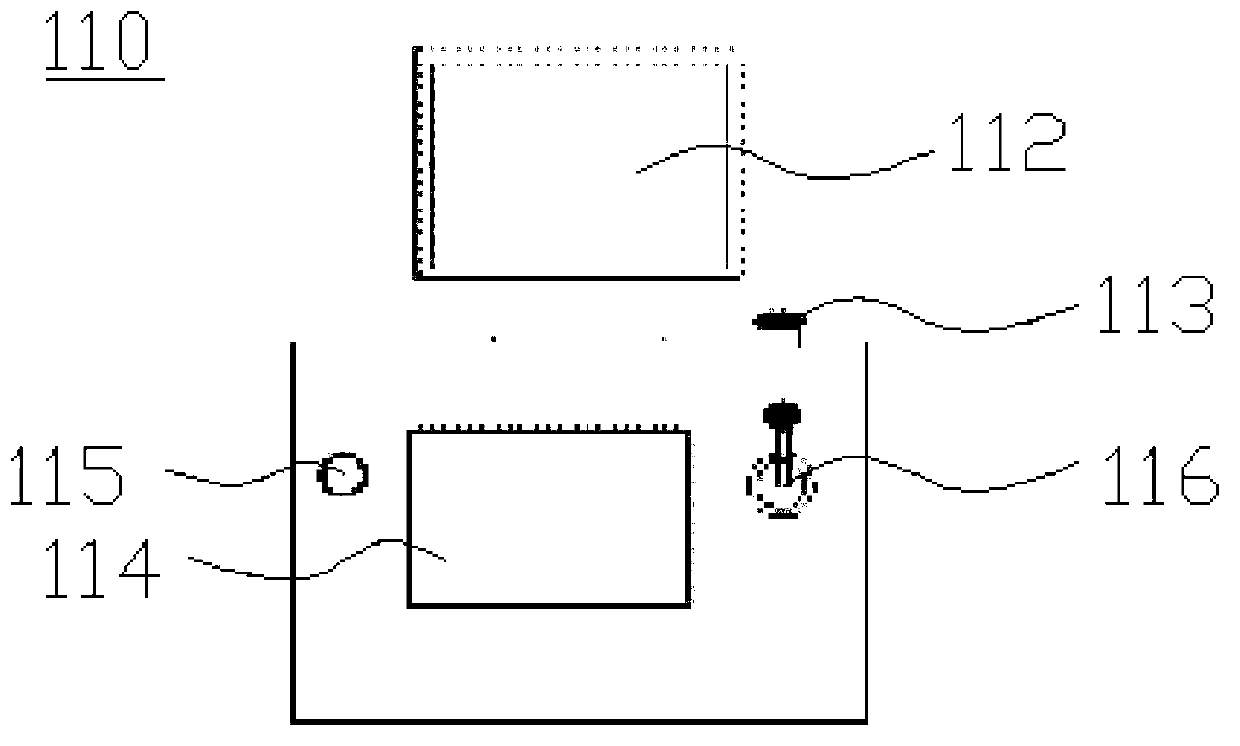

[0022] Such as figure 1 As shown, a mechanical operating arm with charged water for electric power washing includes an operation panel 110, which can issue action commands; a control computer 120 connected to the operation panel 110, and the control computer 120 receives the operation The action command issued by the panel 110 is decomposed into corresponding motion signals; the mechanical arm 130 includes a movable joint assembly 132, the joint assembly 132 is connected with the control computer 120, and the joint assembly 132 executes the control computer 120 The decomposed motion signal; the water gun 140 is installed on the joint assembly 132, and the water gun 140 can be connected to the outlet of the water pump.

[0023] The above-mentioned electric power flushes the mechanical operation arm with electrified water, the water gun 140 is installed on the joint assembly 132 of the mechanical arm 130, the water inlet of the water gun 140 is connected with the water pump outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com