Die-casting die

A die-casting mold and mold frame technology, applied in the field of mechanical processing, can solve the problems of increased product cost, complicated operation, high product defective rate, etc., and achieve the effect of improving the problem of stuck punches and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

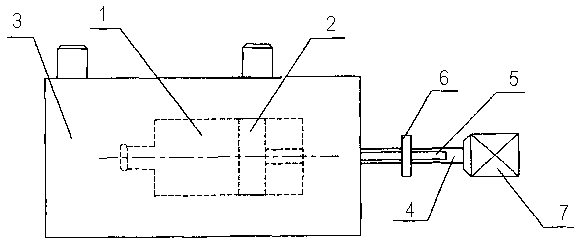

[0007] Such as figure 1 As shown, a die-casting mold includes a mold frame 3 and a mold cavity 1 disposed therein. An insert 2 with the same width is arranged in the mold cavity 1, and two guide posts arranged in parallel are provided on one side of the mold frame 3 5 and the guide sleeve supporting plate 6 arranged on it, a screw 4 is pierced in the middle of the guide sleeve supporting plate 6, one end of which is connected with the insert 2 in the mold cavity 1, and the other end is connected with a servo motor 7.

[0008] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof shall fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com