Rail wagon bearing seal cover removing machine

A technology of bearing sealing and cover pulling machine, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and high labor intensity of operation, and achieve the improvement of work efficiency, reduction of labor intensity, structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

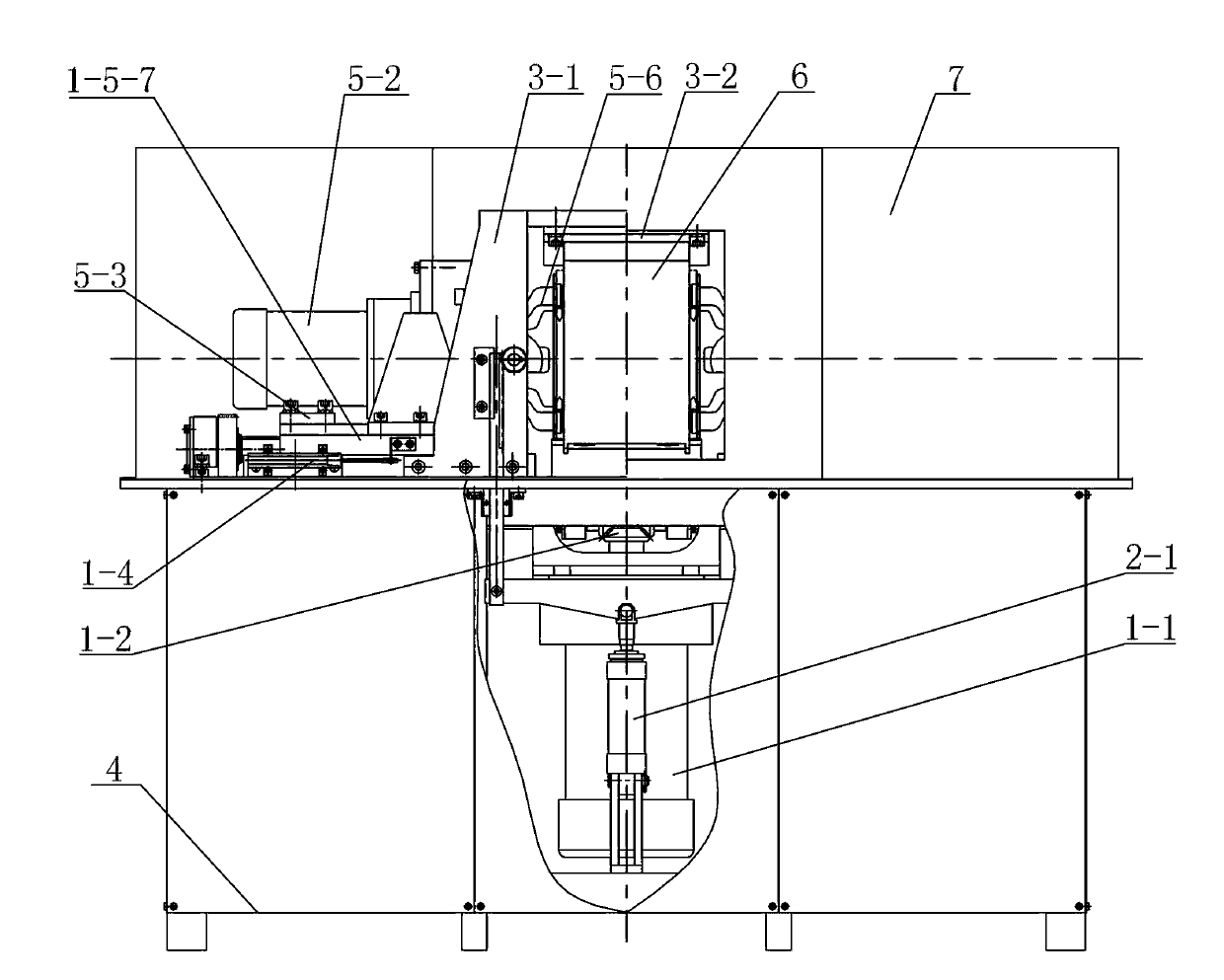

[0009] Specific implementation mode one: combine Figure 1-Figure 10 Describe this embodiment mode, a kind of machine that pulls out the sealing cover of railway freight car bearing in this embodiment mode comprises transmission device 1, ejection mechanism 2, fixing device 3, frame 4 and two sets of cover pulling mechanisms 5;

[0010] The transmission device 1 includes a first motor 1-1, a first bevel gear 1-2, two second bevel gears 1-3, two first electronic rulers 1-4 and two sets of drive mechanisms 1-5, the first A motor 1-1 is installed on the frame 4, the output shaft of the first motor 1-1 is vertically arranged, the first bevel gear 1-2 is fixedly installed on the output shaft of the first motor 1-1, two second The bevel gear 1-3 is arranged on both sides of the axis of the first bevel gear 1-2, and the two second bevel gears 1-3 are meshed with the first bevel gear 1-2. The two sets of driving mechanisms 1 -5 is directly arranged on both sides of the axis of the fi...

specific Embodiment approach 2

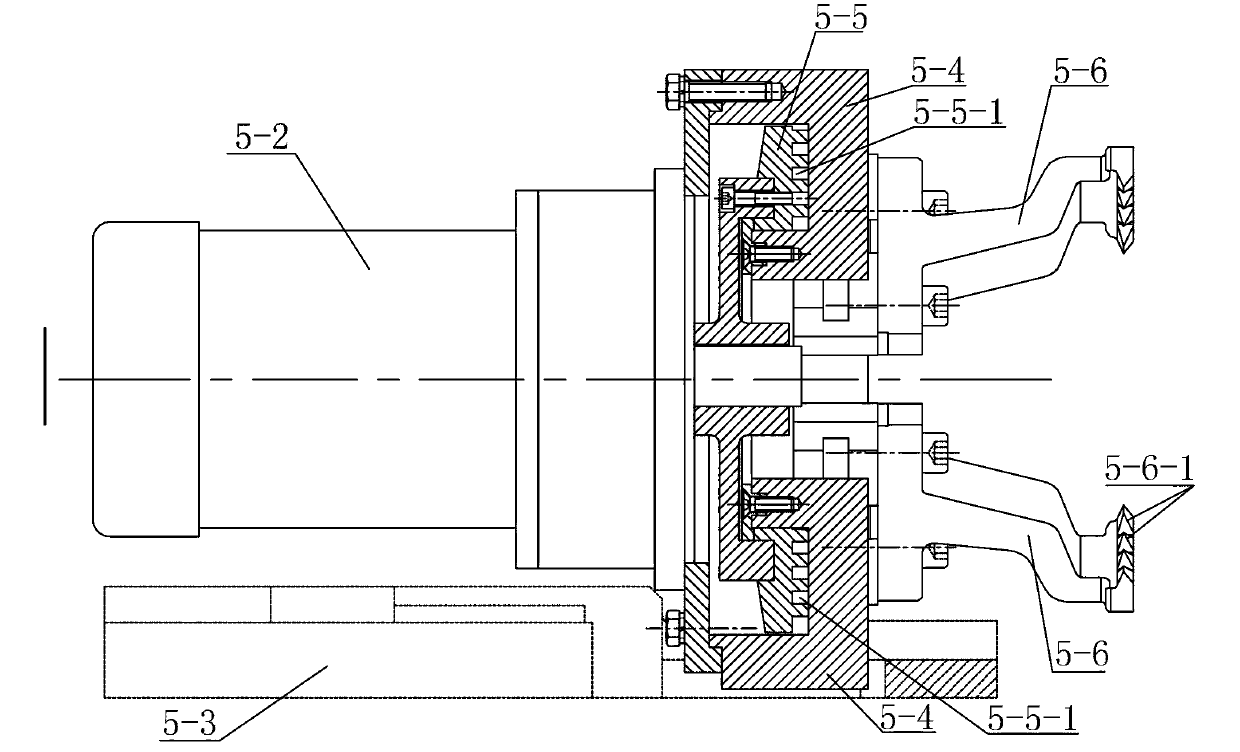

[0013] Specific implementation mode two: combination Figure 5 To illustrate this embodiment, each set of drive mechanism 1-5 in this embodiment includes a shaft rod 1-5-1, a first gear 1-5-2, a second gear 1-5-3, a lead screw 1-5- 4. The screw seat 1-5-5, the guide rail 1-5-6 and the slider 1-5-7, the shaft 1-5-1 is set horizontally, and the second cone is installed at one end of the shaft 1-5-1 Gear 1-3, the other end of the shaft rod 1-5-1 is equipped with a first gear 1-5-2, the first gear 1-5-2 meshes with the second gear 1-5-3, the second gear 1-5-2 5-3 is installed on the lead screw 1-5-4, and the lead screw 1-5-4 is installed on the lead screw seat 1-5-5 and the two are connected in rotation, and one end of the slider 1-5-7 is connected to the lead screw 1-5-4 thread connection, the other end of the slider 1-5-7 is installed on the guide rail 1-5-6, and the slider 1-5-7 can slide horizontally on the guide rail 1-5-6, the guide rail 1 -5-6 is installed on the upper su...

specific Embodiment approach 3

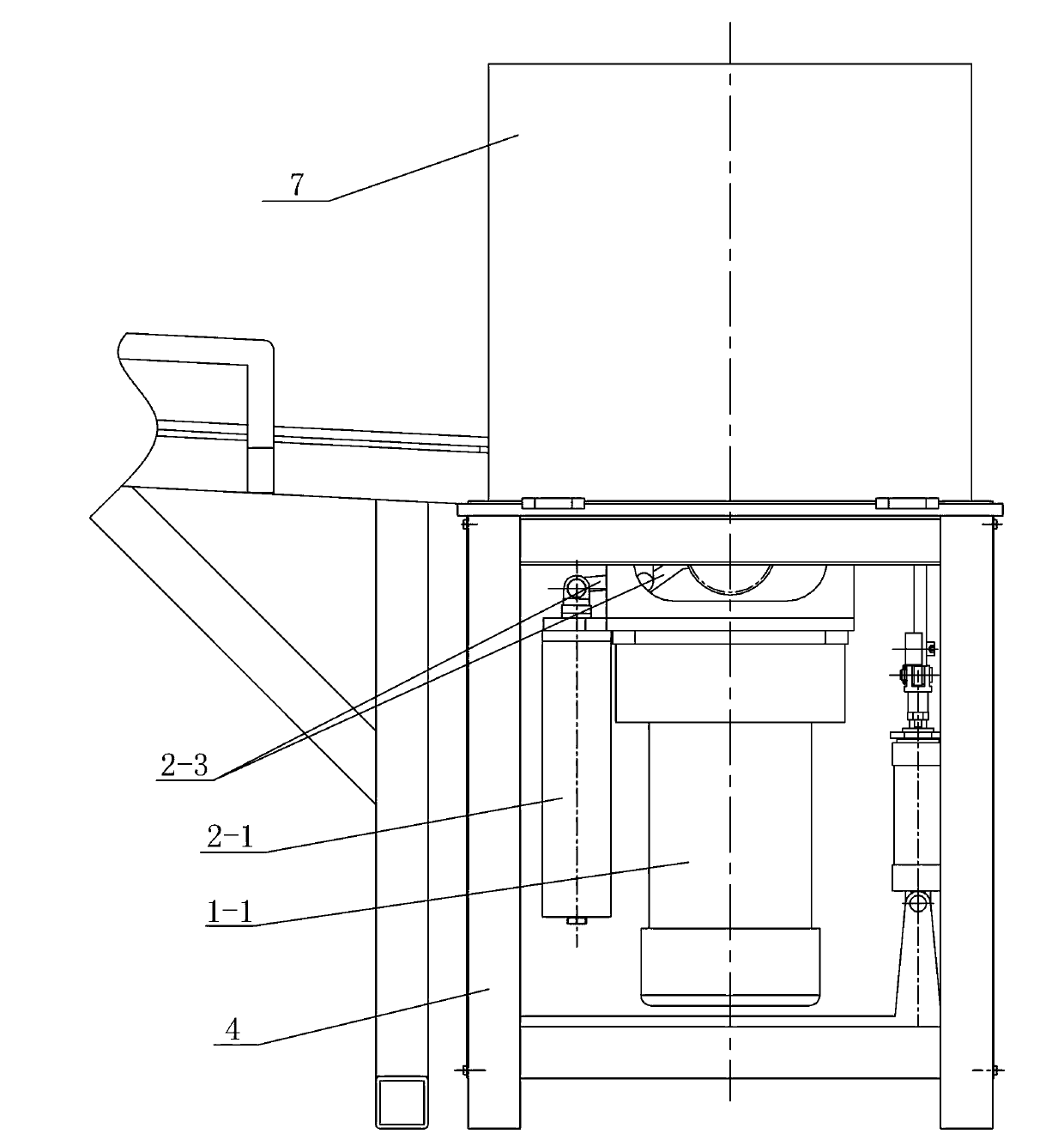

[0014] Specific implementation mode three: combination Figure 6 and Figure 7 To illustrate this embodiment, the ejector mechanism 2 in this embodiment includes a first cylinder 2-1, a cylinder bracket 2-2, a lever 2-3, a push rod 2-4, a top plate 2-5 and a lower tire block 2-6 , the cylinder bracket 2-2 is installed on the frame 4, the first cylinder 2-1 is installed on the cylinder bracket 2-2, the end of the driving rod of the first cylinder 2-1 is hinged with one end of the lever 2-3, and the lever The other end of 2-3 is hinged with the cylinder bracket 2-2, the lower tire block 2-6 is installed on the upper surface of the frame 4, the top plate 2-5 is rotationally connected with the lower tire block 2-6, and the push rod 2-4 One end is rotatably connected with the top plate 2-5, the other end of the push rod 2-4 is rotatably connected with the lever 2-3, the lower tire block 2-6 is used for supporting the bearing, and the top plate 2-5 is used for ejecting the bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com