Nesting integral lifting building structure

A technology of overall improvement and construction, applied in building structure, construction, etc., can solve problems such as hidden dangers of personal safety, harassment of nearby residents and pedestrians, injuries to ground construction personnel or pedestrians, etc., to shorten the construction period and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

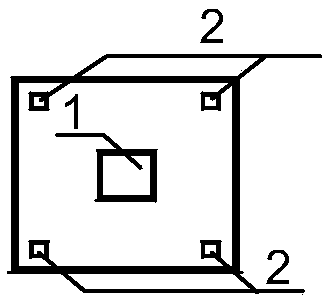

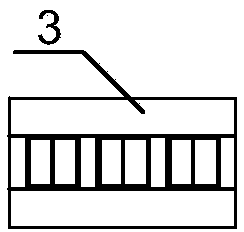

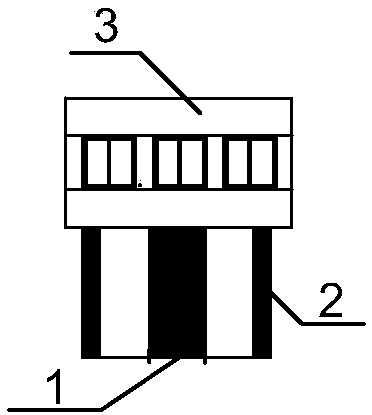

[0006] Specific implementation method: the power drive adopted in this program is a double-acting through-the-heart jack, such as Figure 7 , Figure 8 As shown: one end of the jack 9 is fixed on the reinforced concrete core tube 1 or 2, and the other end is connected with the steel pipe column 10, and the steel pipe column 10 is fixed between the two-story frame beams 8. Figure 7 shown), drive the core tube 1 or 2 to lift upwards, in fact Figure 4 and Figure 6 Indicates the construction state of the core tube after the height of one floor is raised inside the building; otherwise, when the jack 9 climbs downward (such as Figure 8 shown), the frame beam 8 is lifted up, as image 3 , Figure 5 The represented building body is lifted up by one floor height. The lifting force depends on the number of jacks installed. The more jacks are installed, the greater the lifting force will be. It is based on the load and self-weight of the building. After the construction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com