A screw and scroll composite mud pump

A mud pump and vortex technology, which is applied in the field of construction of check dams, can solve the problems of limited solid particle size, uncontrollable mud concentration, and difficulty in ensuring personal safety, so as to reduce dehydration and consolidation time and improve dam construction. Efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

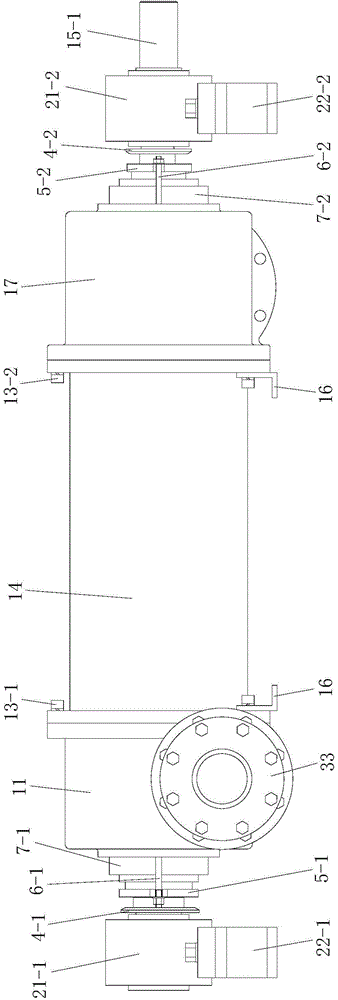

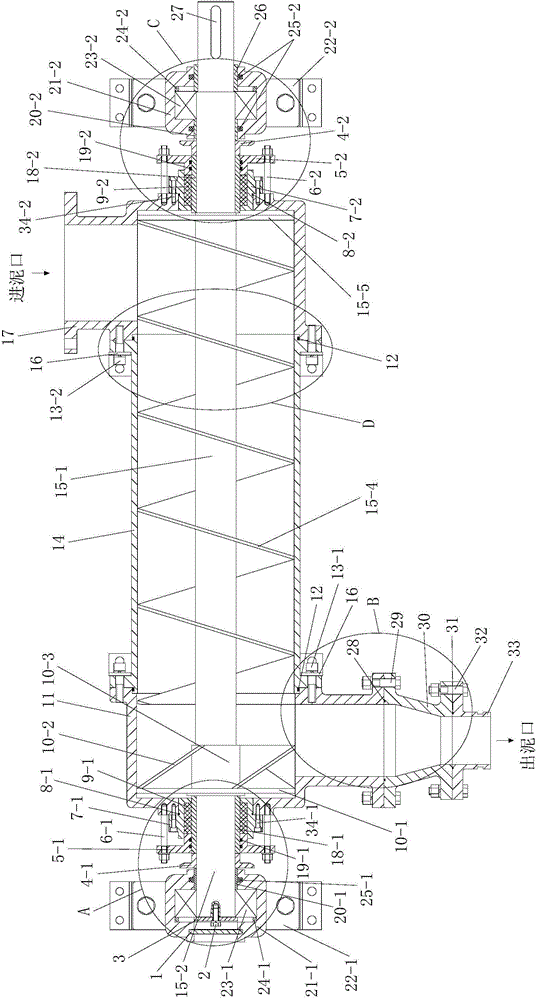

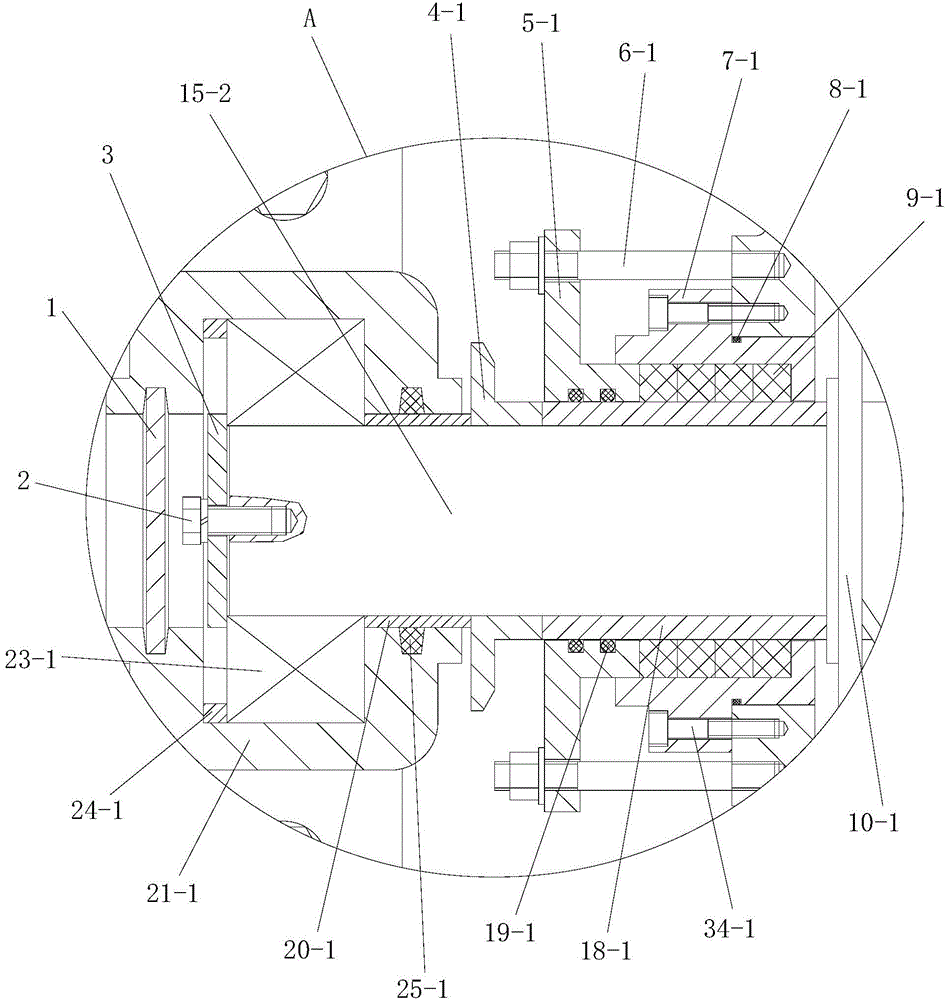

[0037] like figure 1 , figure 2 , Figure 8 and Figure 9 As shown, the present invention includes a cylinder body 14 and a pump shaft. The cylinder body 14 is cylindrical and has connecting flanges at both ends. The pump shaft passes through the cylinder body 14 in the axial direction and both ends are located in the cylinder body. Outside the body 14, one end of the cylinder body 14 is sealed and fixed with a casing 11, and the other end of the cylinder body 14 is sealed and fixed with a mud inlet joint 17, and the pump shaft is coaxially arranged and fixedly connected with the first pump shaft 15-2 and the second pump shaft 15-1, the outer end of the first pump shaft 15-2 passes through the casing 11, and the outer end of the second pump shaft 15-1 passes through the mud inlet joint 17. A helical blade 15-4 is installed on the second pump shaft 15-1 located in the cylinder body 14 and the mud inlet joint 17, and the cylinder body 14, the second pump shaft 15-1 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com