Protective rails for rolling shutter doors

A technology for rolling shutter doors and guide rails is applied in the field of rolling shutter door guide rails to achieve the effects of neat and beautiful appearance, improved safety and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

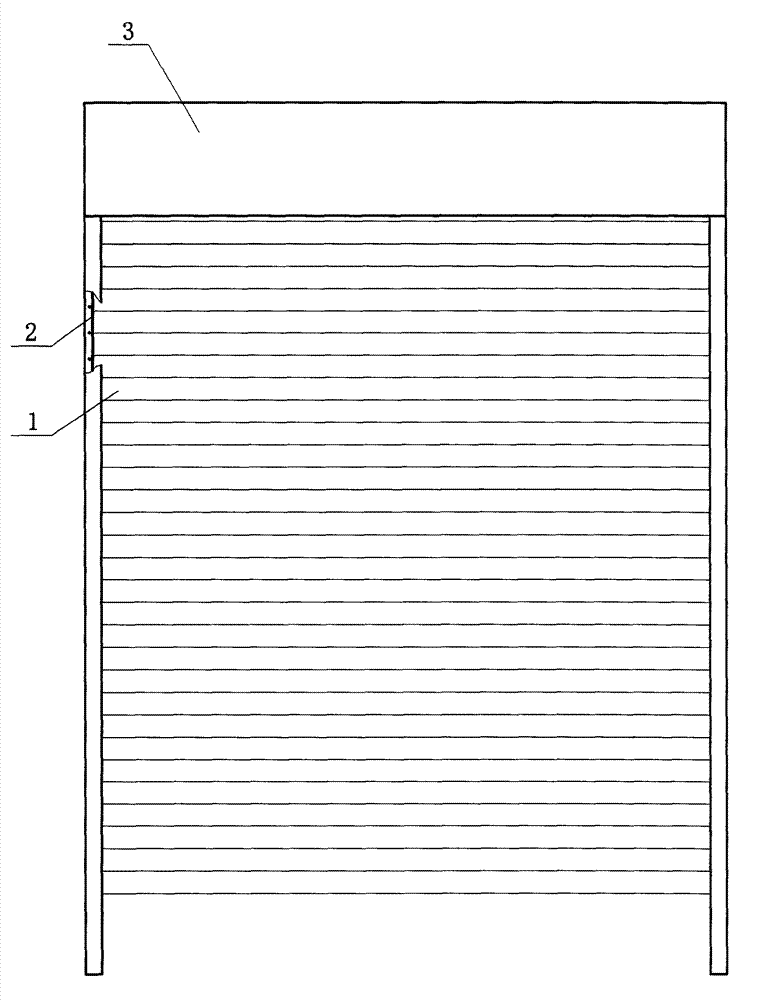

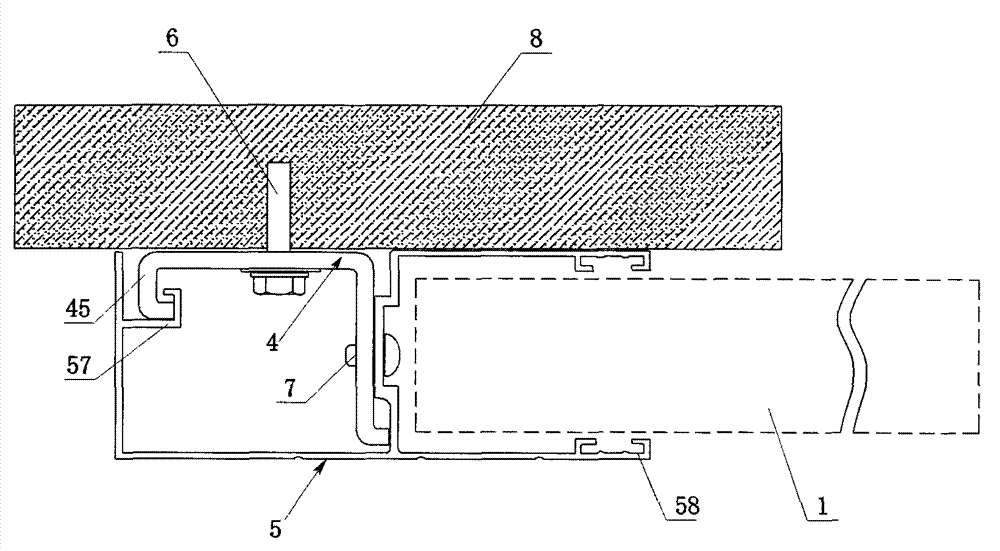

[0022] Embodiment 1: see figure 1 , figure 2 and Figure 4 , The protective guide rail 2 for the rolling door is located on both sides of the doorway or the outer wall (or inner wall) of the window, including a fixed rail 4 and a guide rail 5 .

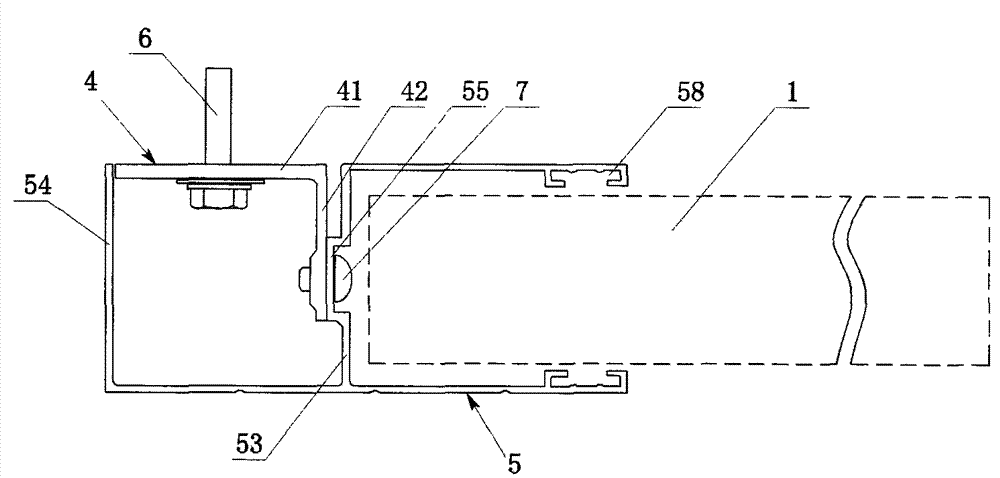

[0023] The fixed rail 4 includes a fixed surface 41 against the wall and a vertical surface 42 . The installation hole provided on the fixed surface 41 of the fixed rail 4 is a horizontal strip hole 43, and the fixed surface is directly fixed on the wall 8 by using the expansion screw 6 (or ordinary screw). During the installation process, the wall may need to be drilled. The verticality of the fixed rail can be adjusted through the strip hole 43 . The fixing surface 41 and the wall body 8 can be installed in various ways, and can be arbitrarily fixed according to the actual installation situation of the user. The wall body 8 can be a brick wall, a concrete wall or a metal wall, etc. The vertical surface 42 of the fixed rail 4 i...

Embodiment 2

[0027] Example 2: see figure 1 and image 3 , the content is basically the same as that of Embodiment 1, the difference is that no hook is provided at the joint between the fixed surface of the fixed rail and the outer facade of the guide rail protection groove described in the guide rail protection groove.

Embodiment 3

[0028] Embodiment 3: The accompanying drawings are not drawn, and the content is basically the same as that of Embodiment 1. The difference is that no grooves may be provided on the facade of the guide rail. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com