Method and system for compensating engine thermal conditions

A technology of engine and engine temperature, which is applied in the direction of combustion engine, engine control, machine/engine, etc. It can solve problems such as valve expansion or contraction, valve event changes, etc., and achieve the effects of reducing vehicle emissions, increasing engine emissions, and reducing engine misfires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

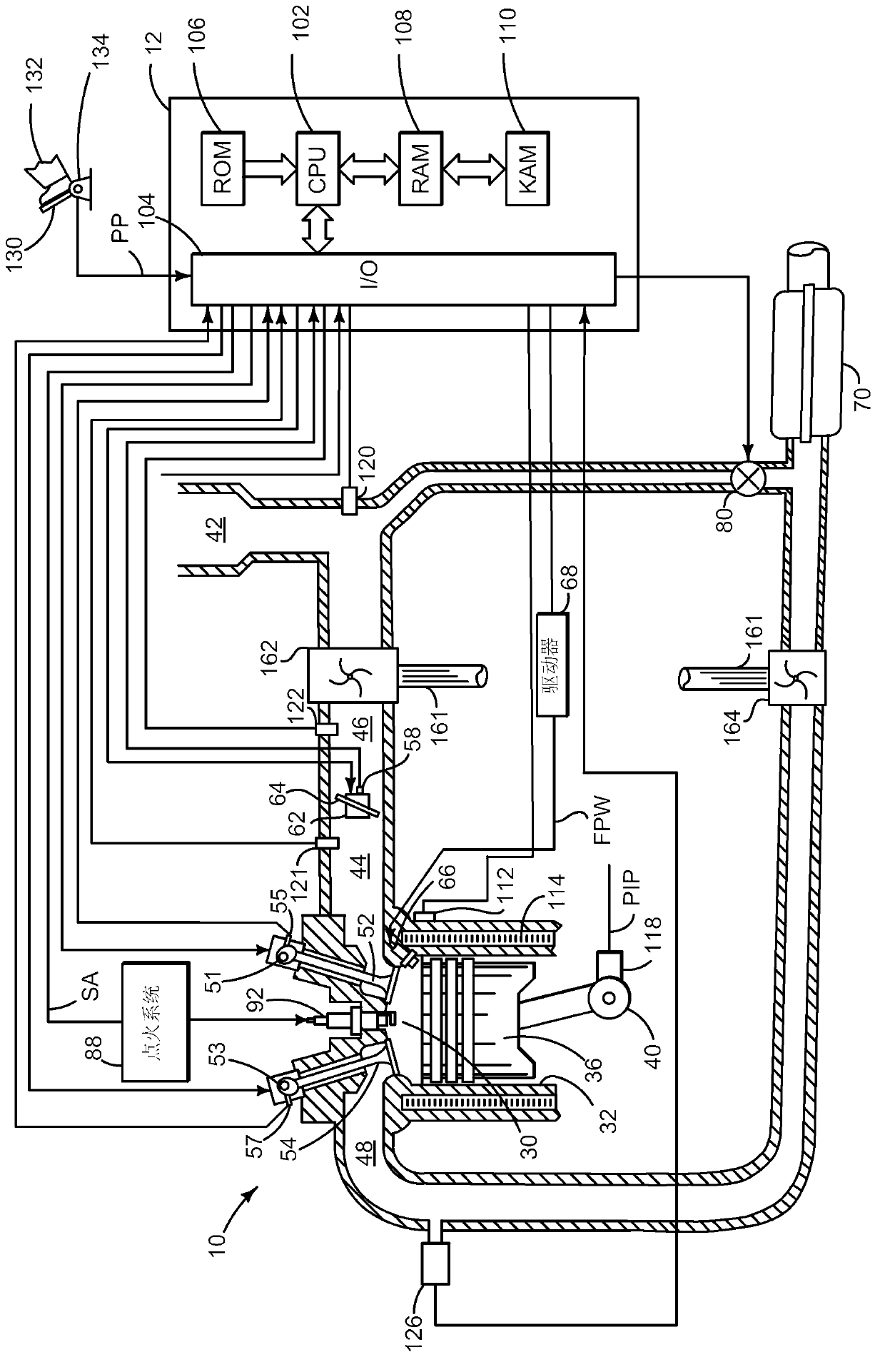

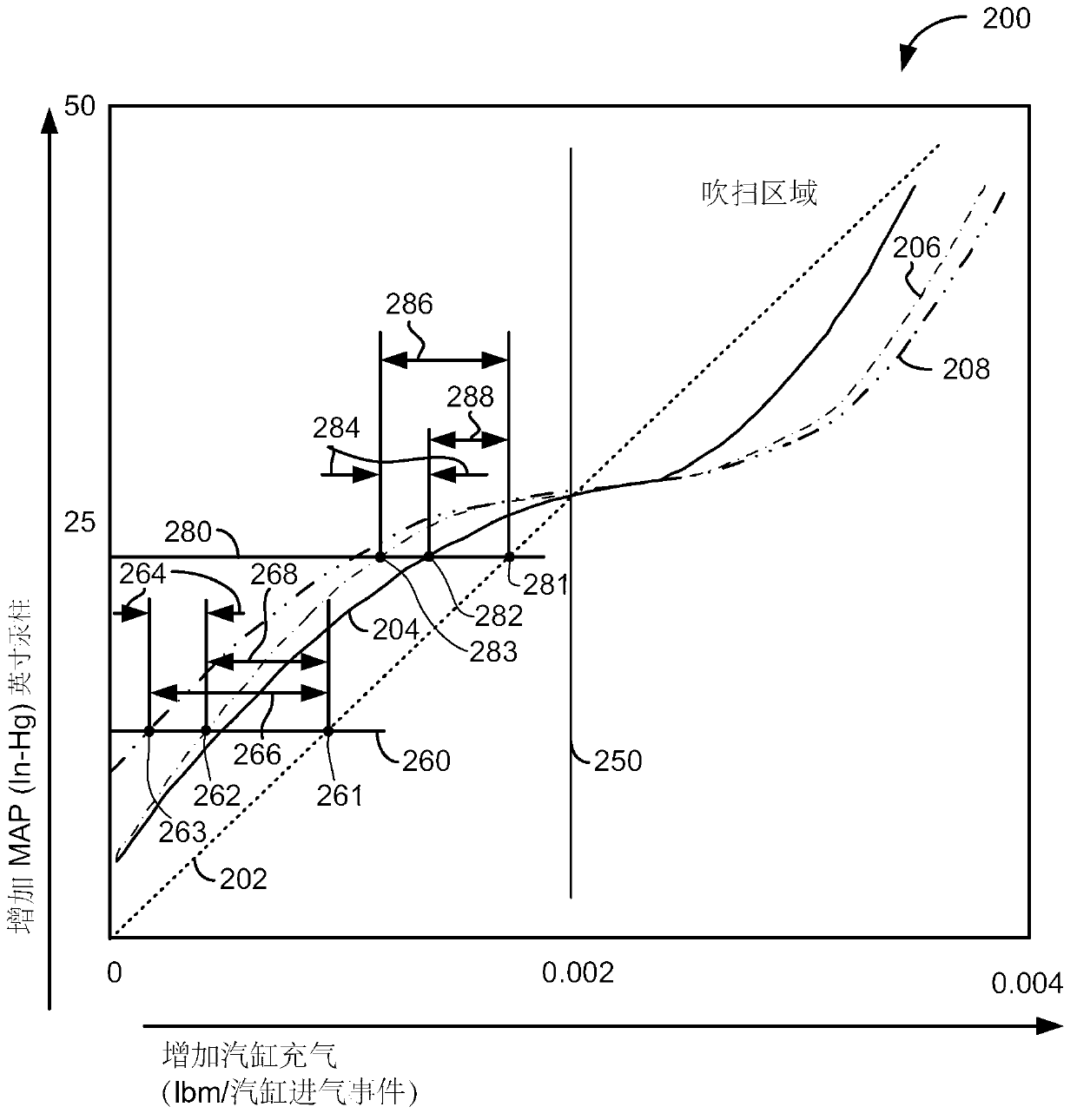

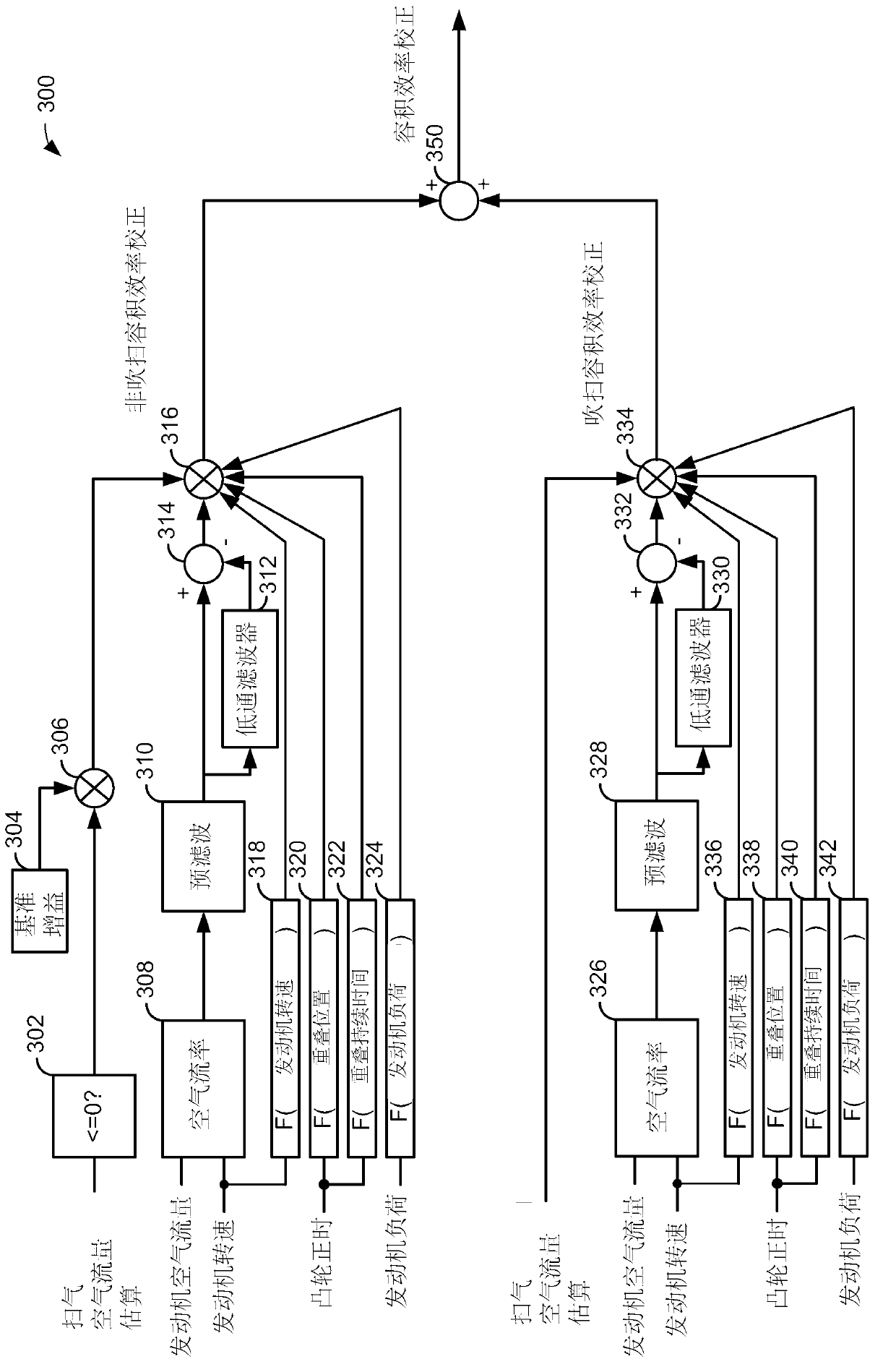

[0014] The present invention relates to regulating the amount of cylinder air and the amount of residual gas in the cylinders of an engine. figure 1 An example system for regulating cylinder air volume of cylinders is shown. In some examples, the system may include a turbocharger and a spark ignited mixture of air and gasoline, alcohol, or gasoline and alcohol. However, in other examples, the engine may be a compression ignition engine, such as a diesel engine. figure 2 An example graph of the simulation is shown, which is the basis for compensating the cylinder air volume and cylinder residual volume. image 3 An example method for adjusting cylinder air volume is shown. exist Figure 4-5 A visual example of how to adjust cylinder air mass, MAP, and cylinder residual mass according to the method described here is shown in . exist Figure 6 A flow diagram of a method for adjusting a cylinder air quantity and a cylinder residual gas quantity is shown in .

[0015] now re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com