Safe processing device of low-temperature hydrogen in rocket engine thrust chamber

A technology for rocket engine and safe handling, which is applied in rocket engine units, jet propulsion units, machines/engines, etc. to ensure safety and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

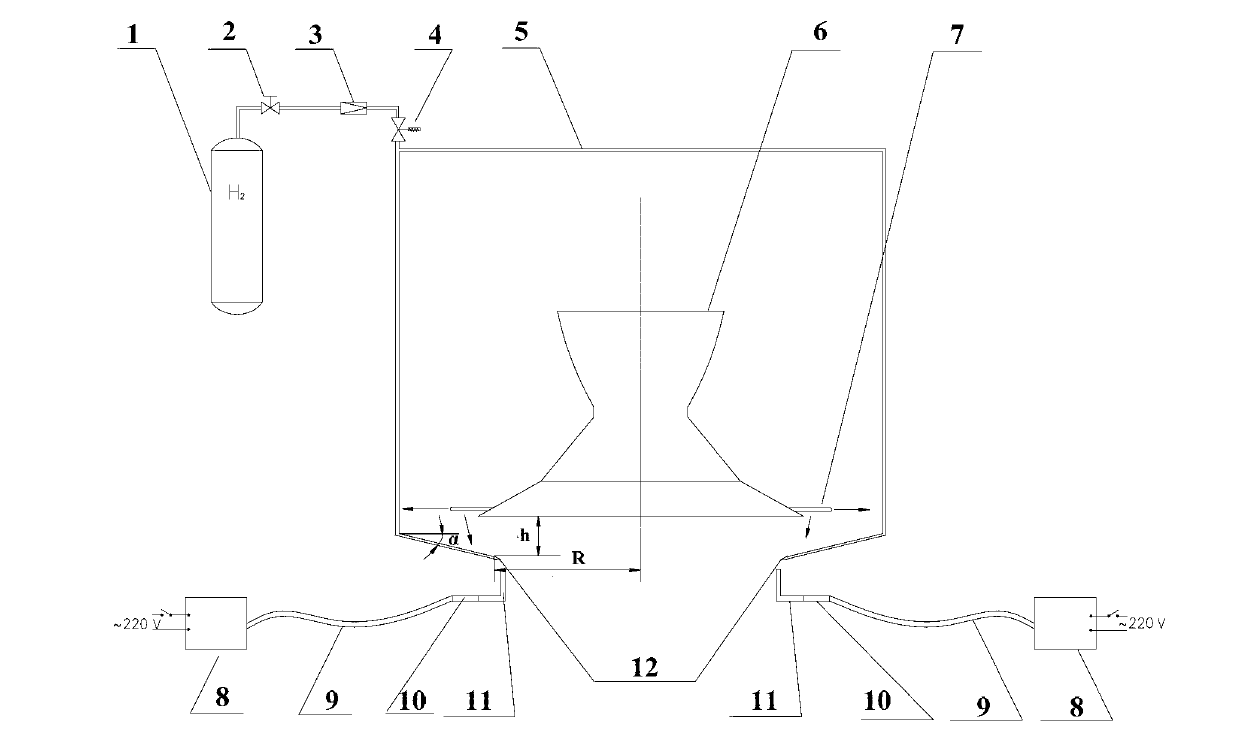

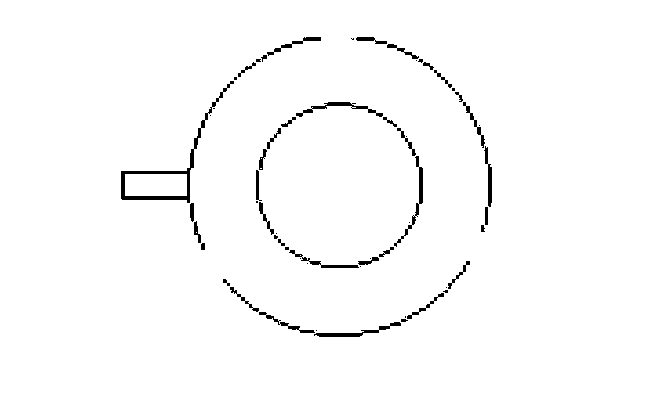

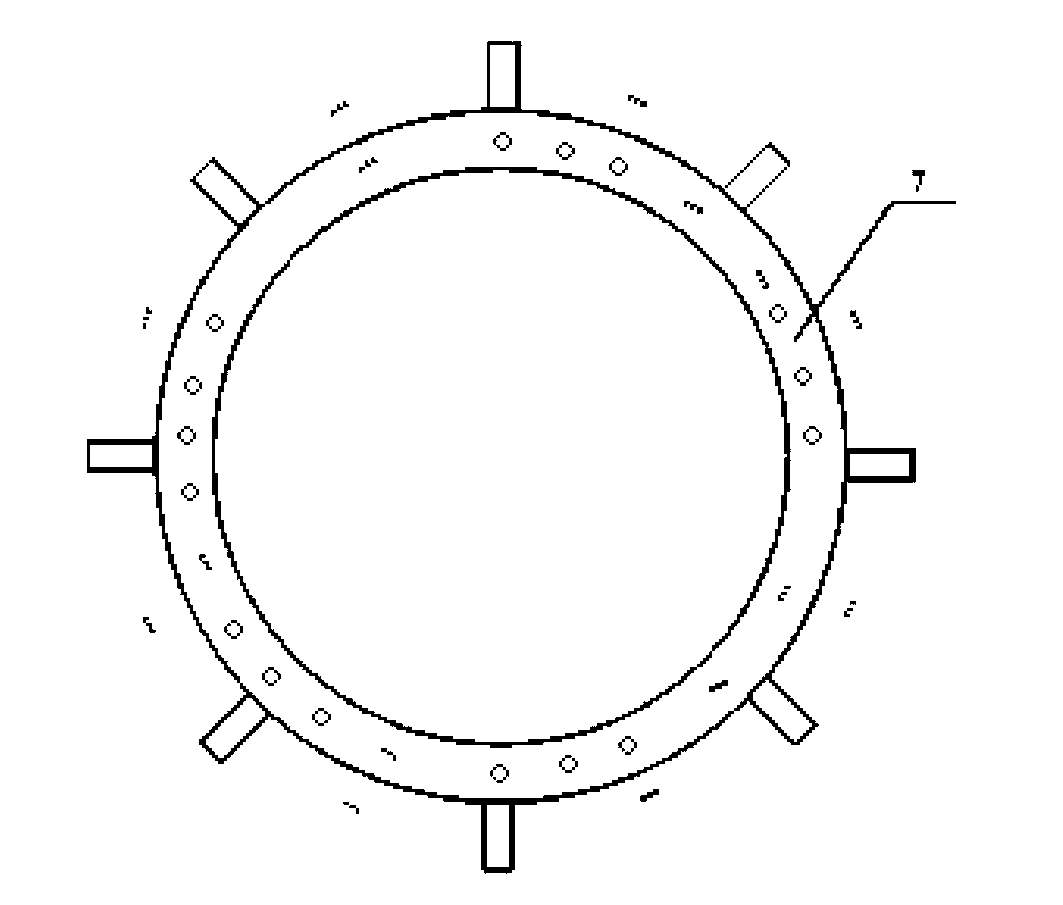

[0021] Such as figure 1 As shown, the present invention is mainly composed of a hydrogen cylinder 1, a manual switch 2, a pressure reducing valve 3, a solenoid valve 4, a hydrogen pipeline 5, a nitrogen drainage ring 7, a high-energy electronic igniter 8, a high-voltage cable 9, a conductive rod 10, and a high-energy semiconductor Electric nozzle 11 and hydrogen nozzle 12 are composed of hydrogen bottle 1, manual switch 2, pressure reducing valve 3, solenoid valve 4, hydrogen pipeline 5, and hydrogen nozzle 12 to form an ever-burning torch; high-energy electronic igniter 8, high-voltage cable 9, The conductive rod 10 and the high-energy semiconductor electric nozzle 11 form an electronic ignition system; the nitrogen gas diversion ring 6 serves as a low-temperature hydrogen flame diversion system. When the present invention works, first turn on the manual switch 2, adjust the opening of the decompression valve 3 so as to adjust the gas source pressure of the hydrogen cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com