Atomic frequency standard servo method with temperature compensation and circuit

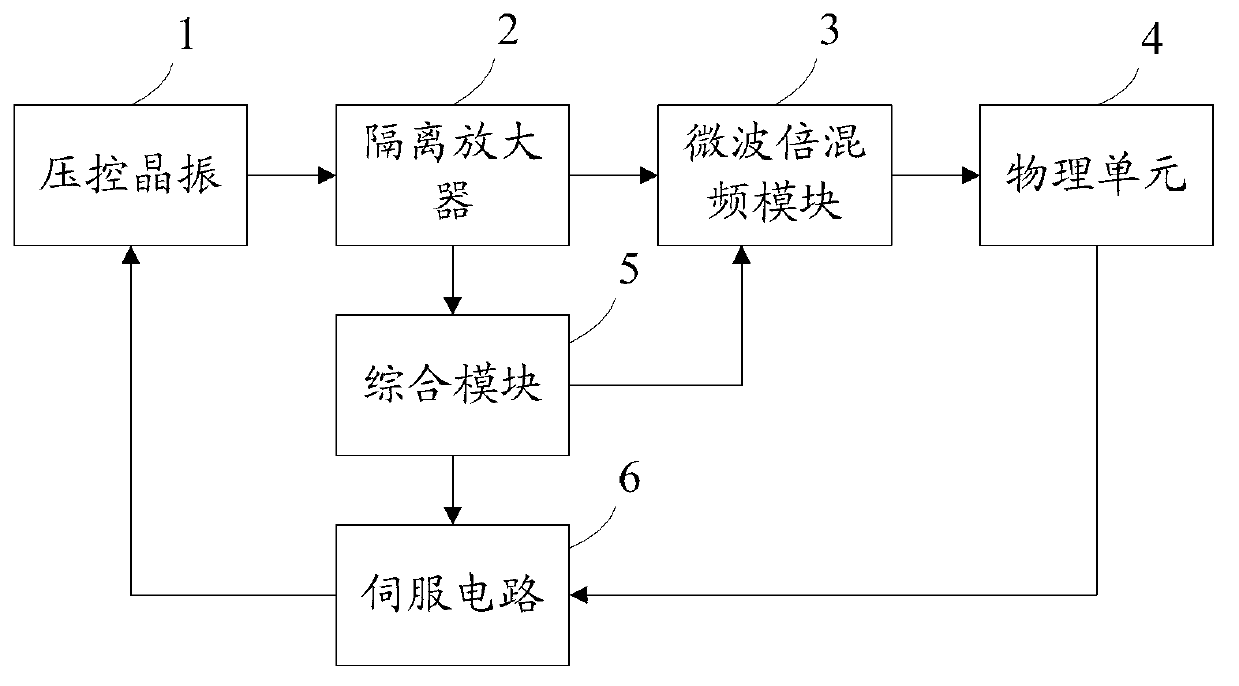

An atomic frequency standard and temperature compensation technology, which is applied in the direction of electrical components and automatic power control, can solve the problems of low output accuracy of atomic frequency standard, unable to solve the problem of temperature change voltage-controlled crystal oscillator output change, etc., and achieve the output frequency Stable and Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

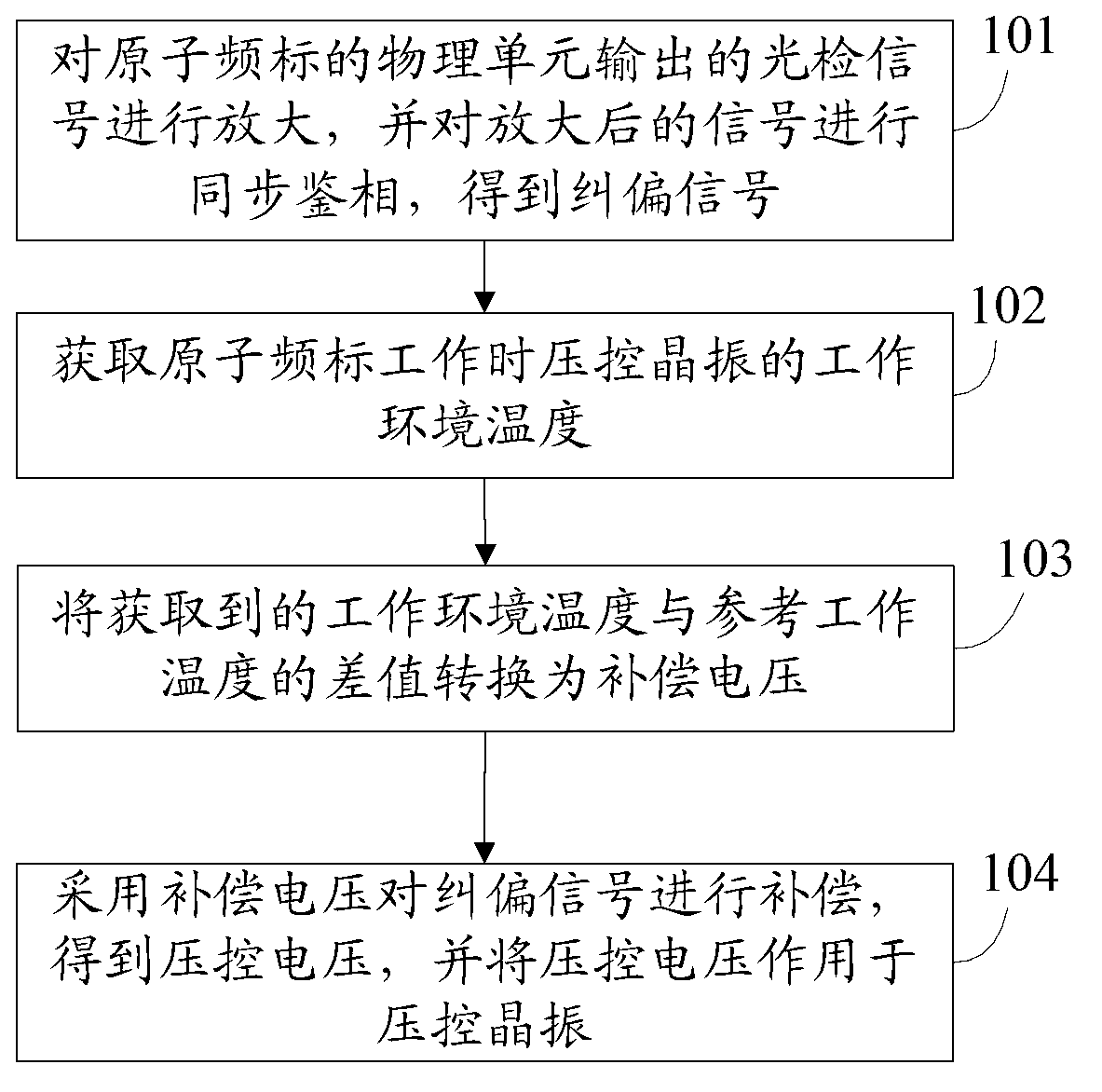

[0050] An embodiment of the present invention provides an atomic frequency standard servo method with temperature compensation, see figure 2 , the method includes:

[0051] Step 101: Amplify the optical detection signal output by the physical unit of the atomic frequency standard, and perform synchronous phase detection on the amplified signal to obtain a deviation correction signal.

[0052] Specifically, the optical detection signal output by the physical unit of the atomic frequency standard is amplified, including:

[0053] Obtain the optical detection signal output by the physical unit of the atomic frequency standard;

[0054] The acquired photodetection signal is amplified by using an amplifying circuit of a differential instrument.

[0055] Step 102: Obtain the working environment temperature of the voltage-controlled crystal oscillator when the atomic frequency standard is working.

[0056] Specifically, a thermistor attached to the surface of the voltage-controll...

Embodiment 2

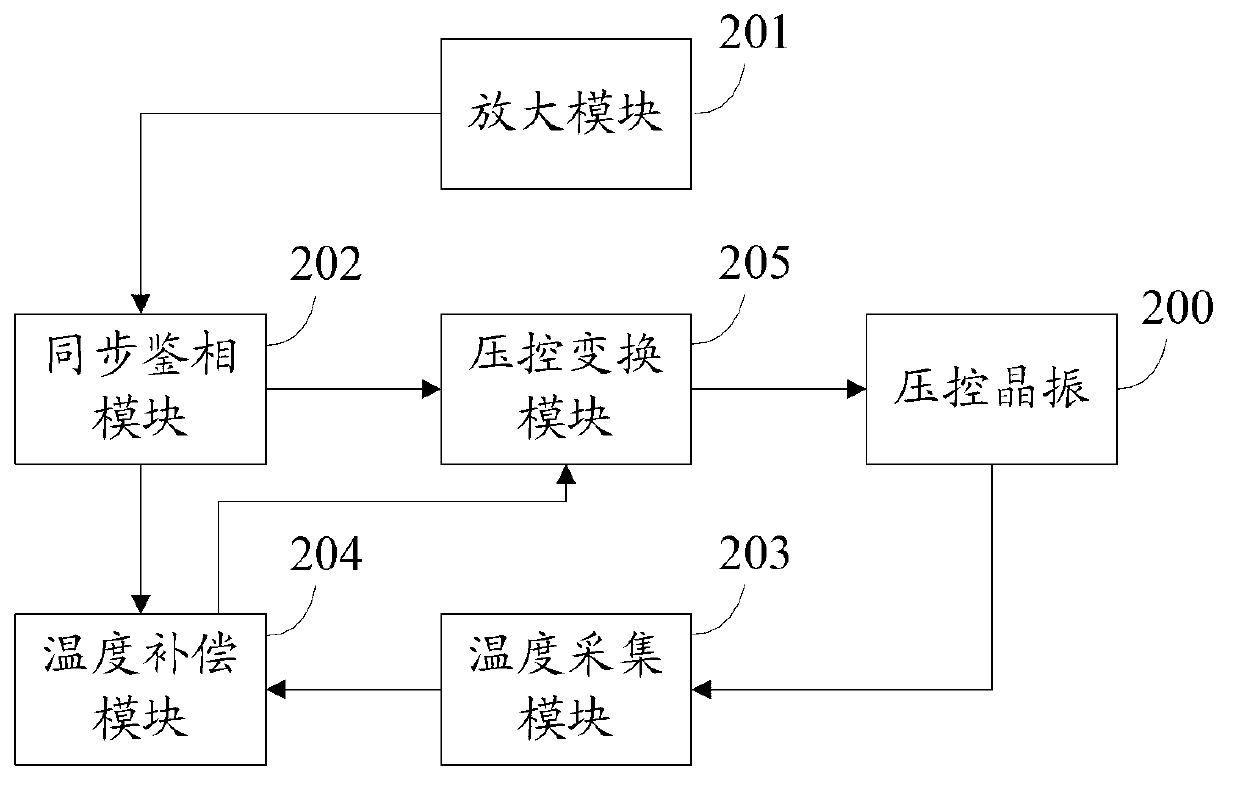

[0065] An embodiment of the present invention provides an atomic frequency standard servo circuit with temperature compensation, see image 3 , the circuit consists of:

[0066] Amplifying module 201, for amplifying the optical detection signal output by the physical unit of the atomic frequency standard;

[0067] The synchronous phase detection module 202 is used to perform synchronous phase detection on the signal amplified by the amplification module 201 to obtain a deviation correction signal;

[0068] The temperature acquisition module 203 is used to obtain the working environment temperature of the voltage-controlled crystal oscillator 200 when the atomic frequency standard is working;

[0069] A temperature compensation module 204, configured to convert the difference between the obtained working environment temperature and the reference working temperature into a compensation voltage;

[0070] The voltage-controlled conversion module 205 is configured to use the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com