Multi-workpiece processing drilling, tapping, milling and boring compound CNC machine tool

A technology of composite CNC machine tools and processing drills, which is applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve problems such as inability to quantify the improvement of workpiece efficiency, excessive consumption of machine tool materials, and unfavorable environmental protection. Effectiveness of utilization rate, saving tool change time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

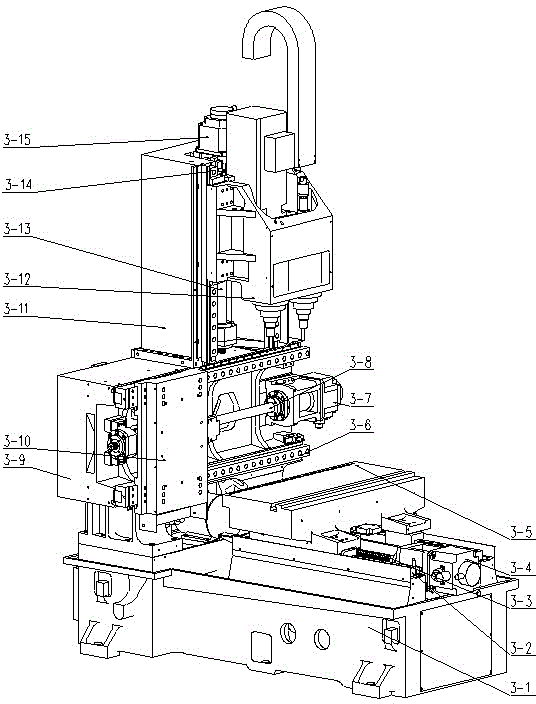

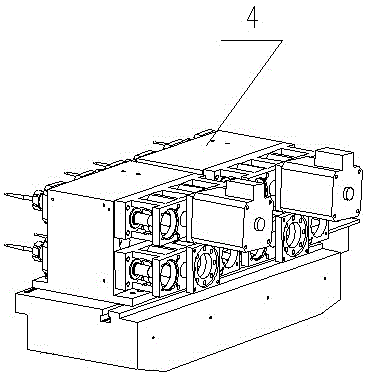

[0012] Embodiment 1: with reference to attached Figure 1-5 . A multi-workpiece processing drilling, tapping, milling and boring compound numerical control machine tool, including an electric control system, an X-axis saddle 3-9 is vertically installed on one end of a machine base 3-1, and a Z-axis worktable 3-5 passes through a Z-axis roller rail 3 -2 is installed on the machine tool base 3-1, the Z-axis ball screw 3-3 cooperates with the Z-axis worktable 3-5 and drives the Z-axis ball screw 3-3 to drive the Z-axis to work through the Z-axis servo motor 3-4 The table 3-5 moves along the Z-axis roller rail 3-2; the X-axis roller rail 3-6 is installed on the inner side of the X-axis saddle 3-9, and the X-axis table 3-10 is located on the X-axis On the X-axis roller rail 3-6, the X-axis servo motor 3-7 is installed on the X-axis saddle 3-9 between the X-axis roller rail 3-6, and the X-axis servo motor 3-7 passes through the X roller The screw rod 3-8 drives the X-axis table 3-...

Embodiment 2

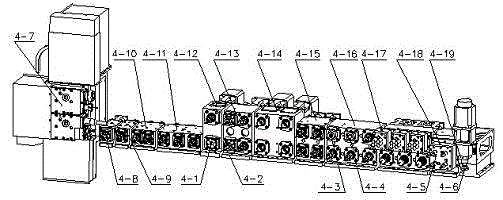

[0017] Embodiment 2: with reference to attached Figure 5 . On the basis of Embodiment 1, the modular combined power seat 4 is a servo synchronous belt that drives multiple main shaft transmission mechanisms, and the servo synchronous belt drives the servo motor 6-3 in the multiple main shaft transmission mechanisms through the coupling 6-2 and The driving main shaft 6-1 on the power base is connected, the synchronous belt pulley 6-4 is installed on the driving main shaft 6-1 and the driven main shaft 6-6 and the driven shaft 6-6 is located on the power base, and the synchronous belt pulley Through the transmission effect of the synchronous belt, the driven main shaft 6-6 is made to perform forward and reverse rotation motions, and one servo motor drives multiple driven main shafts to move. That is, the power base is provided with a synchronous belt adjustment wheel 6-5. The power base is provided with a transition shaft, and a transition pulley is installed on the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com