Large-span integrated beam structure of gantry machine tool and manufacturing method

A technology of gantry machine tool and manufacturing method, which is applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc., can solve problems such as deformation of large-span beams, and achieve the effects of reducing welding time, small deformation, and reducing transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

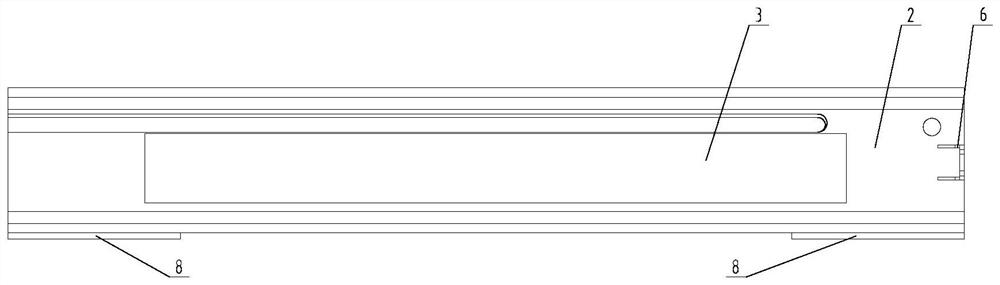

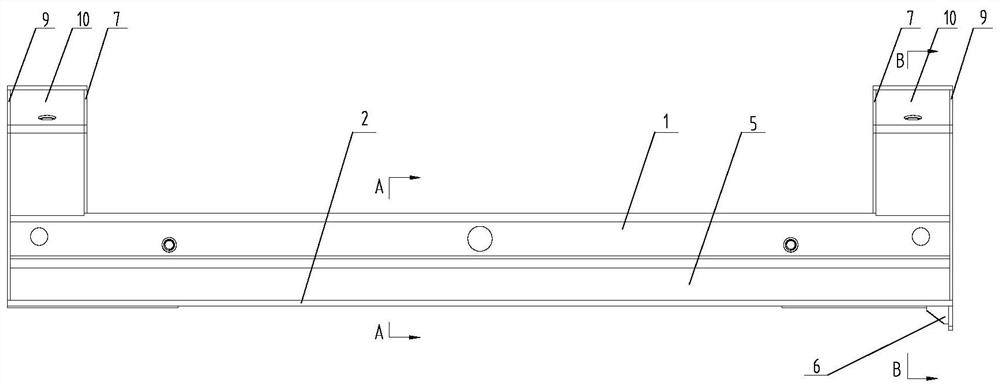

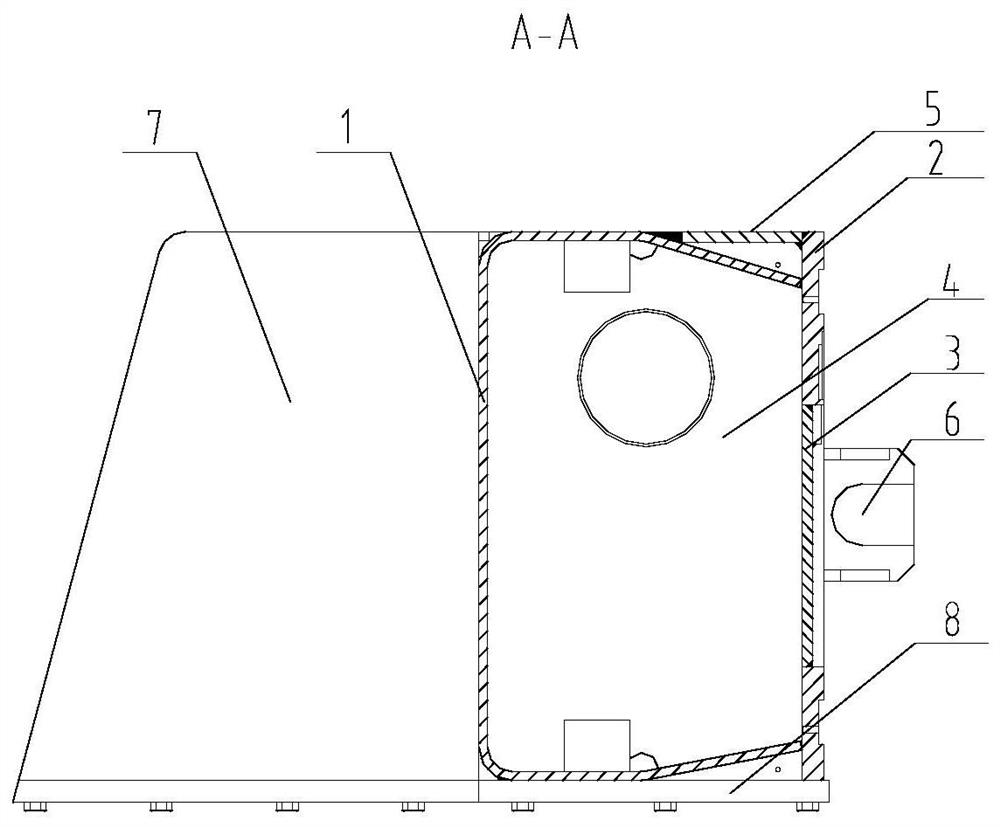

[0019] This kind of gantry machine tool has a large-span integrated beam structure, see Figure 1-10 , including beam ribs and the protruding part of the joint surface between the beam end and the column, which is characterized by an integrated beam structure: the C-shaped inner wall of the entire back panel 1 is welded to the side of the support end of the beam rib 4 at intervals, and the frame panel of the front panel 2 and the core panel 3 are welded with the other side of the supporting end of the crossbeam rib plate 4, and then welded with two end plates 9, the column mounting panel 8, and the connecting plate 5; the front panel includes the frame panel 2 and the core panel 3, and the front panel The height of the frame panel 2 of the panel is equal to the height of the beam, the length of the frame panel 2 is equal to the length of the beam, the center of the frame panel 2 is a square window, and the four sides are connected; the size of the core panel 3 is equal to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com