Method for preparing compound fertilizer through stirring type temperature feedback aerobic/anaerobic sludge garbage composting

A temperature feedback, anaerobic sludge technology, applied in the direction of fertilizer mixture, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of high investment and operation costs, insufficient composting, poor applicability, etc., to achieve intelligent composting, The effect of promoting sufficient composting and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] This embodiment takes the composting of garbage sludge in karst areas as an example.

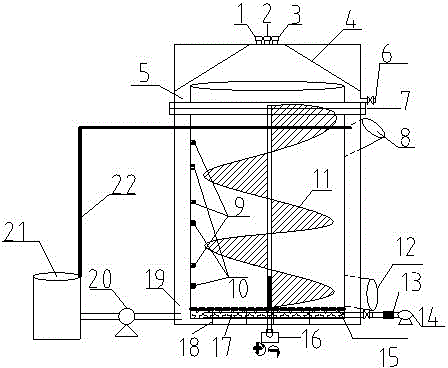

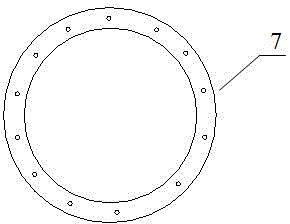

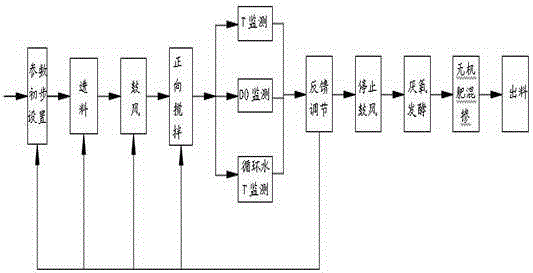

[0021] (1) Set up a stirring type temperature feedback good anaerobic sludge garbage composting compound fertilizer device, which is composed of a compost tank and a temperature feedback adjustment system; the top of the compost tank is equipped with a sensor access hole 1, an exhaust gas detection port 2 and an exhaust gas The collection interface 3, the top of the compost tank includes an air collection hood 4 and a water collection tank 5, the outside of the water collection tank 5 is provided with a water outlet 6, the flange pad 7 is installed under the water collection tank 5, and the upper part of the compost tank is provided with a feed inlet 8, composting The lower part of the outer side of the tank is provided with a discharge port 12, and the inner side of the composting tank is equipped with a dissolved oxygen probe 9 and a temperature probe 10 respectively. A screw propuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com