Prepressing type water uniform-distribution device

A distribution device and pre-pressing technology, which is applied to the configuration of equipment for processing textile materials, etc., can solve the problems that the distribution speed cannot be further improved, and the water distribution device cannot evenly disperse water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

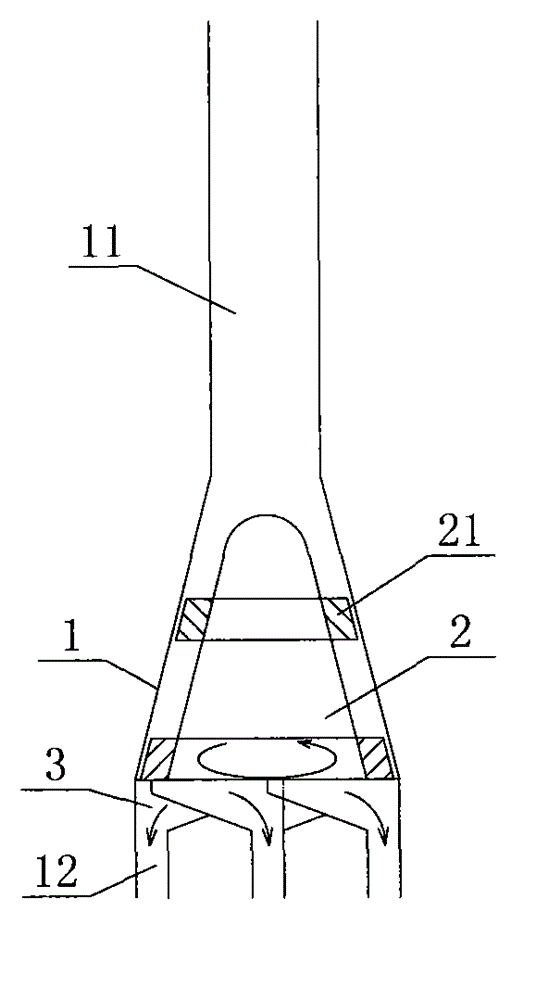

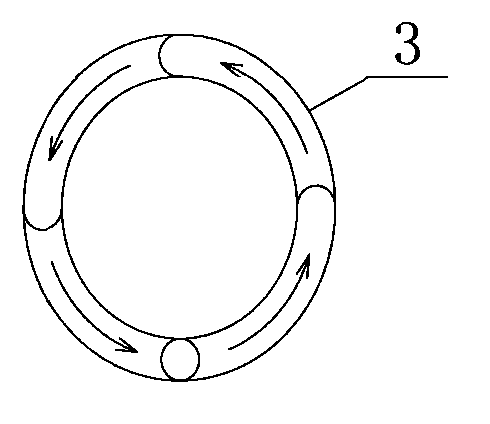

[0021] Such as Figure 1-2 As shown, the pre-pressed uniform water distribution device according to Embodiment 1 of the present invention includes a separation cylinder 1, the separation cylinder 1 is a conical cylinder, and the center of the top of the separation cylinder 1 is connected with the vertically installed water inlet pipe 11. The interior of the separation cylinder 1 is provided with a cone 2, the cone 2 is coaxially arranged with the separation cylinder 1, and at least one rotating impeller 21 is installed at the middle or lower part of the cone 2, and the rotating impeller The outer edge of the blade of 21 is close to but not in contact with the inner wall of the separation cylinder 1, and several equally divided separation grooves 3 are arranged around the bottom circumference of the separation cylinder 1, and each separation groove 3 is arc-shaped, and The bottom or side of each separation tank 3 is connected with a water outlet pipe 12 .

[0022] When two rot...

Embodiment 2

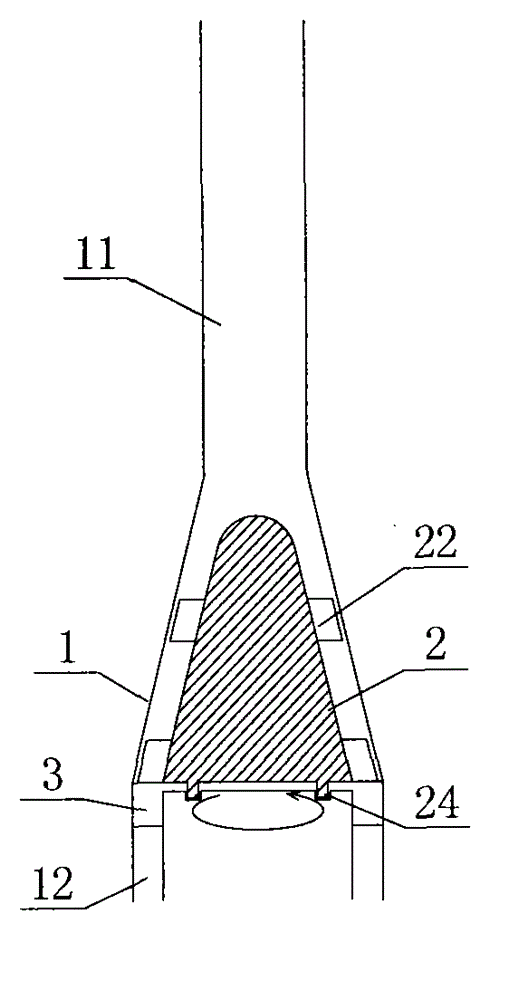

[0026] Such as image 3 As shown, the pre-pressed uniform water distribution device according to the second embodiment of the present invention includes a separation cylinder 1, the separation cylinder 1 is a conical cylinder, and the center of the top of the separation cylinder 1 is connected with the water inlet pipe 11 installed vertically. The interior of the separation cylinder 1 is provided with a cone 2, the cone 2 is coaxially arranged with the separation cylinder 1, and the center of the bottom of the cone 2 is provided with a rotating shaft to connect with the separation cylinder or the bottom of the cone 2 is connected to the separation cylinder. The cylinders are matched by rotating grooves 24, and at least one circle of rotating blades 22 is fixed at the middle or lower part of the cone body 2. The outer edge of the rotating blades 22 is close to but not in contact with the inner wall of the separation cylinder 1, surrounding The bottom circumference of the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com