Construction method of prestressed anchor cable

A technology of prestressed anchor cables and construction methods, which is applied in the direction of foundation structure engineering, buildings, sheet pile walls, etc., and can solve the problem of the difficulty in completely ensuring the grouting quality and prestressing effect of the inner anchorage section, the difficulty in ensuring the grouting pressure of the inner anchorage section, and the difficulty of anchoring In order to improve the overall economic benefits, lower the cost and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

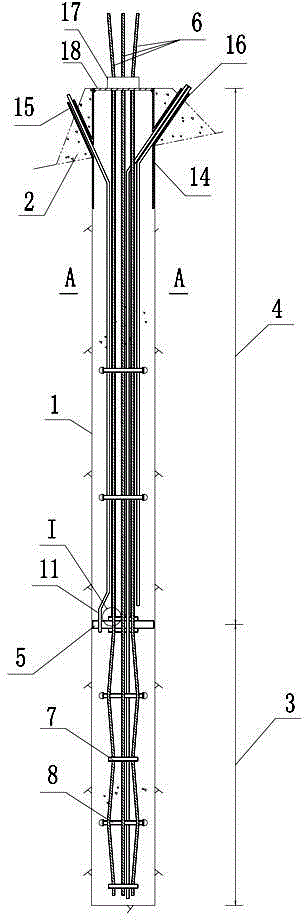

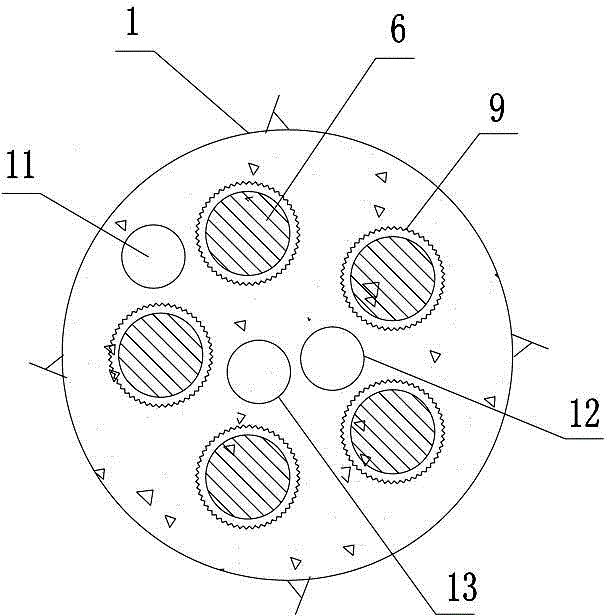

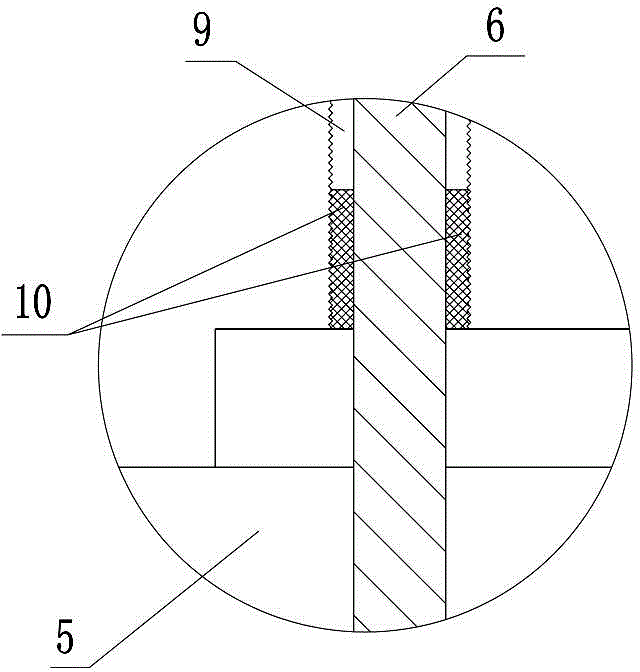

[0014] like figure 1 , 2 , Shown in 3, prestressed anchor cable construction method of the present invention, carry out according to the following steps:

[0015] The first step, according to the design requirements, adopt the drilling method to drill the anchor cable hole 1;

[0016] The second step is to make the anchor cable according to the designed length: the anchor cable is composed of an inner anchor section 3, a tension section 4, and a grout stop ring 5 installed between the interface between the inner anchor section 3 and the tension section 4; the inner anchor section 3 passes through The beam rings 7 and spacers 8 installed alternately on multiple steel strands 6 at intervals are made into a corrugated shape, and the tension section 4 is made into a linear shape through the spacers 8 installed on multiple steel strands 6 at intervals. Each steel strand 6 located in the tension section 4 is fitted with a casing 9, and the lower end of each casing 9 is sealed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com