Liquid micro-flow detection method

A detection method and micro-flow technology, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve the problem that the measurement accuracy cannot be guaranteed, and achieve convenient and simple implementation and meet the system accuracy. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better explain the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

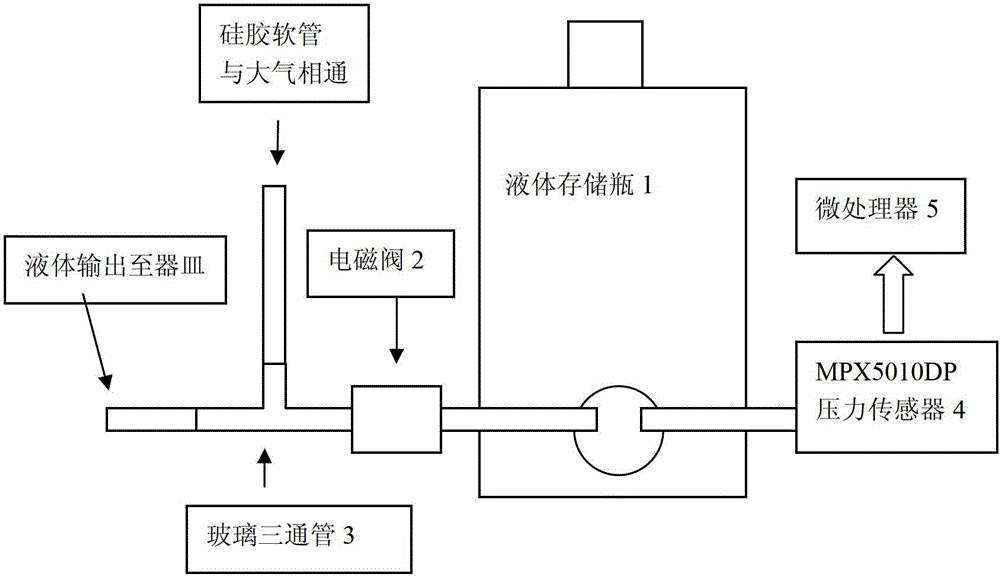

[0021] figure 1 is an application of the present invention, such as figure 1 As shown, it mainly includes a liquid storage bottle 1, a solenoid valve 2, a glass tee pipe 3, a pressure sensor 4 and a microprocessor 5, the liquid storage bottle 1 is used to store the required extraction liquid, and the pressure sensor 4 is installed in the liquid storage The vicinity of the liquid outlet of the bottle 1 is slightly lower than the position of the liquid outlet, and the electromagnetic valve 2 is installed at the liquid outlet, and controls whether to allow the above-mentioned extract to flow out of the liquid storage bottle 1 under the control of the microprocessor 5 . One end of the glass three-way pipe 3 is connected to the output end of the solenoid valve 2, and one end is output to the container, and the third end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com