Sealing film piece leakage measuring device suitable for X fluorescence multi-element analysis meter and method

A multi-element analysis and measurement device technology, applied in the field of sealing diaphragm leakage measurement devices, can solve the problems of wear and leakage of polymer films, poor sealing effect, leakage, etc., and achieve the effect of easy assembly

Active Publication Date: 2013-06-12

DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to long-term use and complex impurities in the pulp, the polymer film will still be worn out, scratched, and even due to the different thermal expansion coefficients of different materials, the sealing effect will become poor after thermal expansion and contraction, resulting in leakage.

[0004] Moreover, when the instrument is working, the head of the detection chamber is immersed b

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

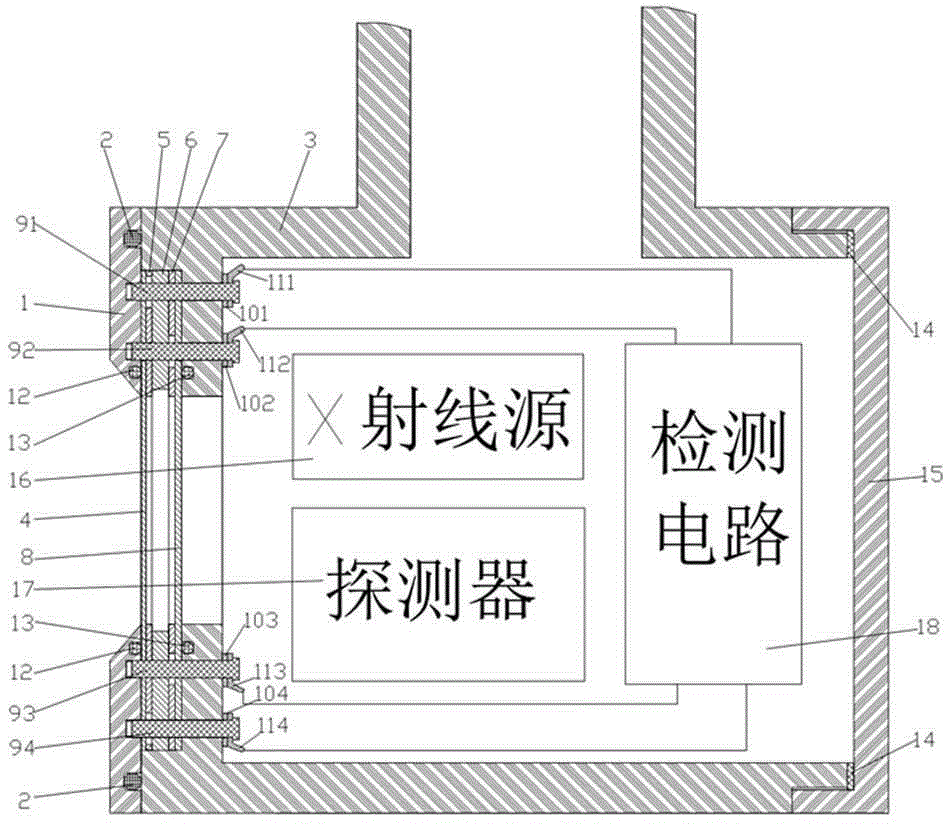

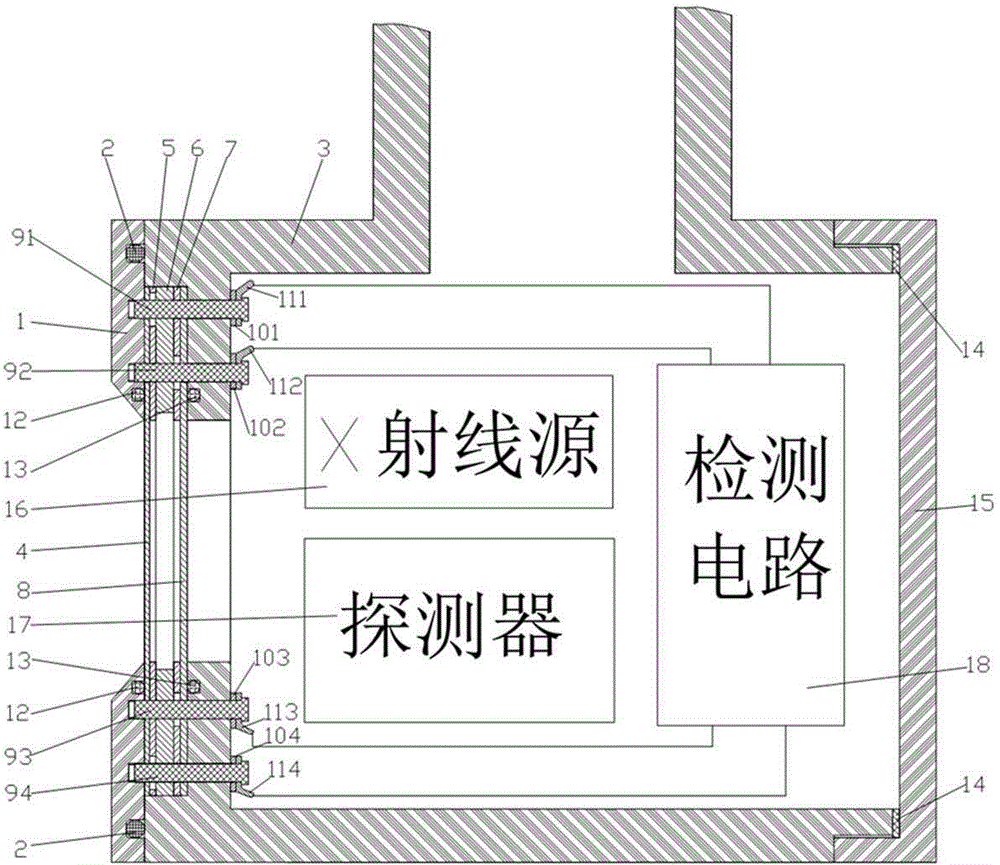

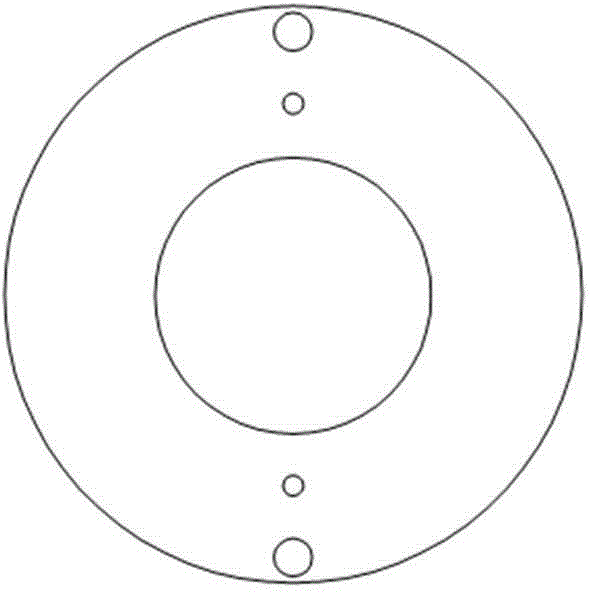

The invention relates to a sealing film piece leakage measuring device suitable for X fluorescence multi-element analysis meter and a method. A double-layer film piece is adopted, thus internal space of a detection cavity body is protected in a sealing mode. Two pieces of copper plates separated by an insulation ring are installed between an inner film piece and an outer film piece. The fact that whether the breakover is formed or not by ore pulp which is contacted between an outer copper plate and an inner copper plate is judged by using the reversing closing of a diode and electrical conductivity of water, thus the fact that whether leakage occurs or not to the sealing of an outer film piece 4 is judged. An alarm signal is delivered by a relay once the leakage of the outer film piece or the line connection breakdown is detected, thus protective measures are started by an instrument.

Description

technical field [0001] The invention relates to a device and method for measuring the leakage of a sealing diaphragm, in particular to a device and a method for measuring the leakage of a sealing diaphragm suitable for X-ray fluorescence multi-element analyzer measurement. Background technique [0002] In the production process of metallurgy, non-ferrous metals, mining, building materials and many other fields in China, the ratio of various elements in raw materials plays a key role in product quality. At present, the in-flow X-ray fluorescence multi-element analysis instrument based on the patented technology "In-flow detection multi-element analysis device and method" (Patent No.: 200710010105.5) has realized the real-time detection of the content of each component element in the material flow, and got rid of the The cumbersome procedure of manual sampling followed by chemical analysis greatly improves production efficiency. [0003] When the instrument measures the ore p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/16

Inventor 张伟佟超于海明龚亚林尹兆余陈树军周洪军金鑫李剑锋王政梁宏伟夏远恒曲宝剑温晓光刘家勇毕然

Owner DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com