Axisymmetric continuous variable Mach spray pipe and wall determining method thereof

A technique for determining the method and Mach number, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as uneven Mach number, poor quality of the outlet flow field, and failure to consider the two-dimensional and three-dimensional characteristics of the flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0034] In the present invention, the Mach number of the supersonic section is greater than 1.2, the Mach number of the subsonic section is less than 0.8, and the Mach number of the transonic section is between 0.8 and 1.2.

[0035] According to an embodiment of the present invention, the wall surface of the axisymmetric continuously variable Mach number nozzle is determined by the following method.

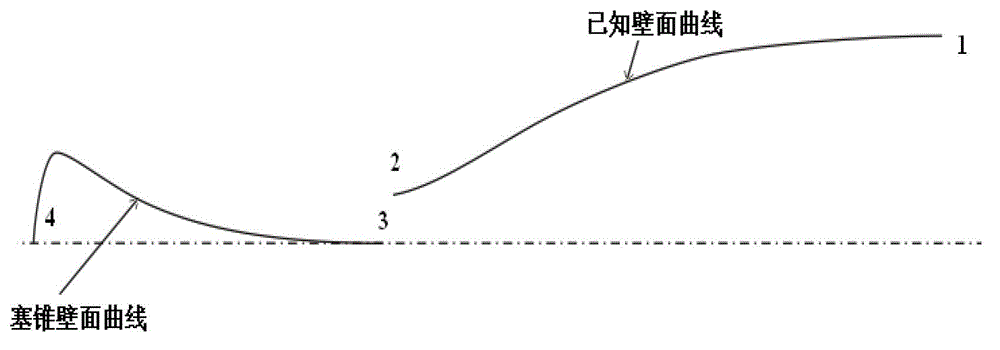

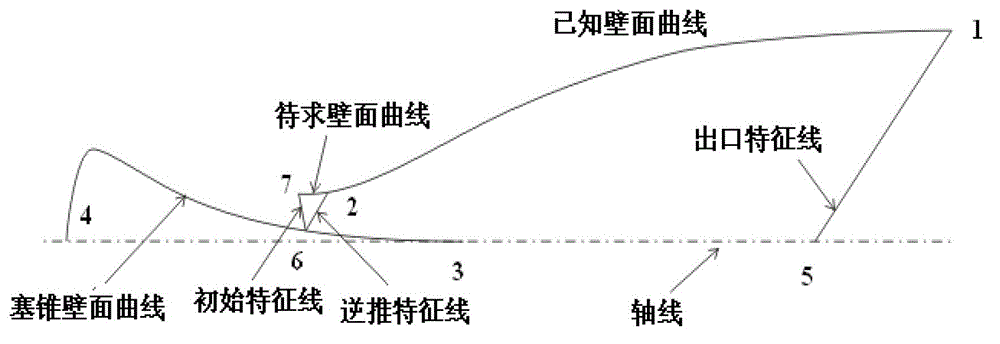

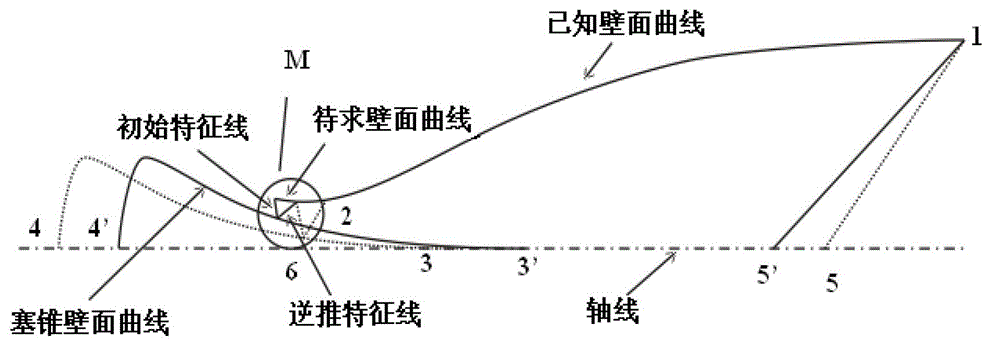

[0036] First, according to the design requirements of the nozzle structure, determine the axis of rotation, the known wall surface curve 1-2, the plug cone wall surface curve 3-4 matched with the known wall surface curve 1-2 line, and the precession distance of the plug cone mechanism and the Mach Number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com