Bowl structure for a centrifugal concentrator

A bowl and liquid technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as not achieving commercial success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

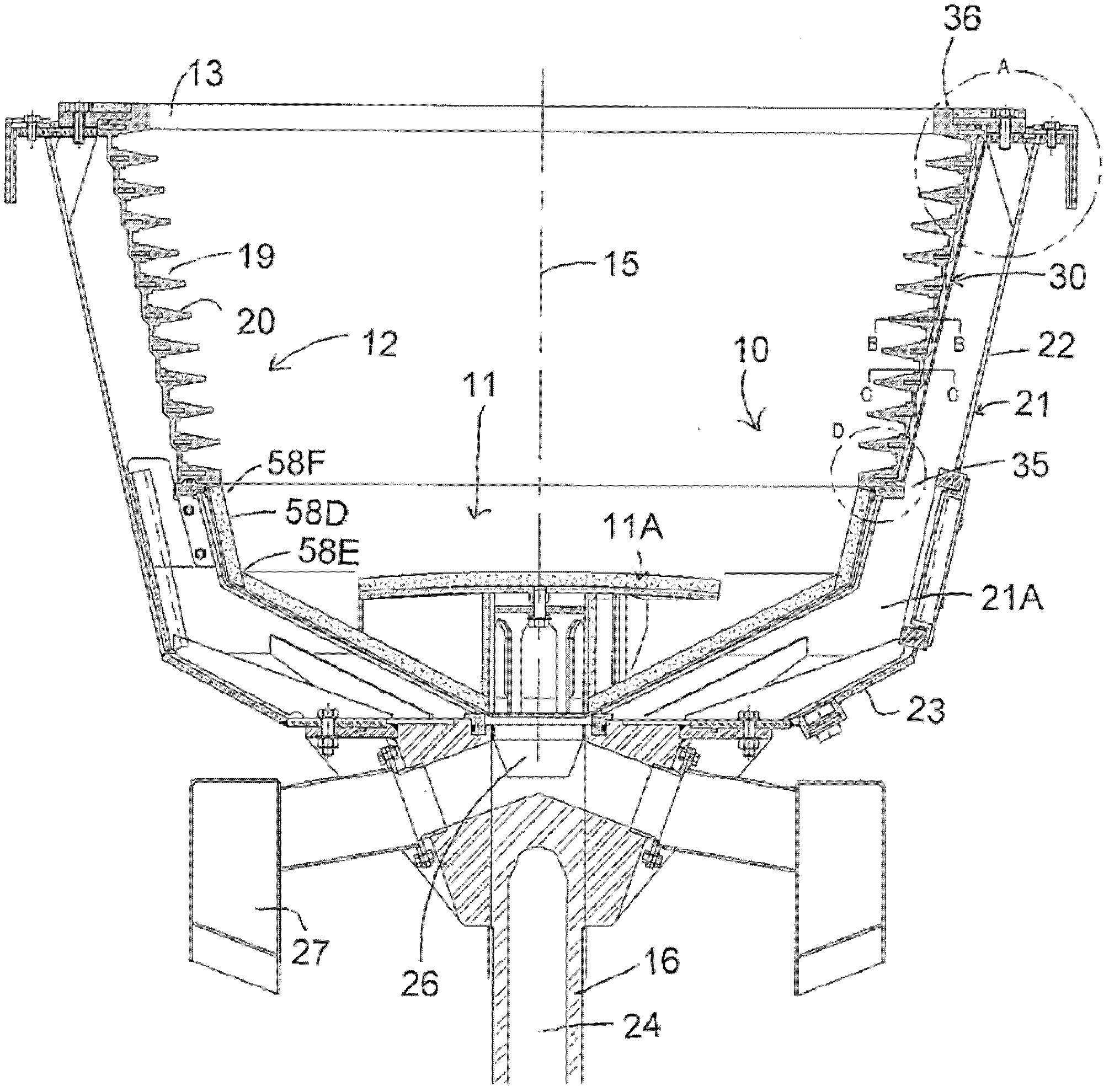

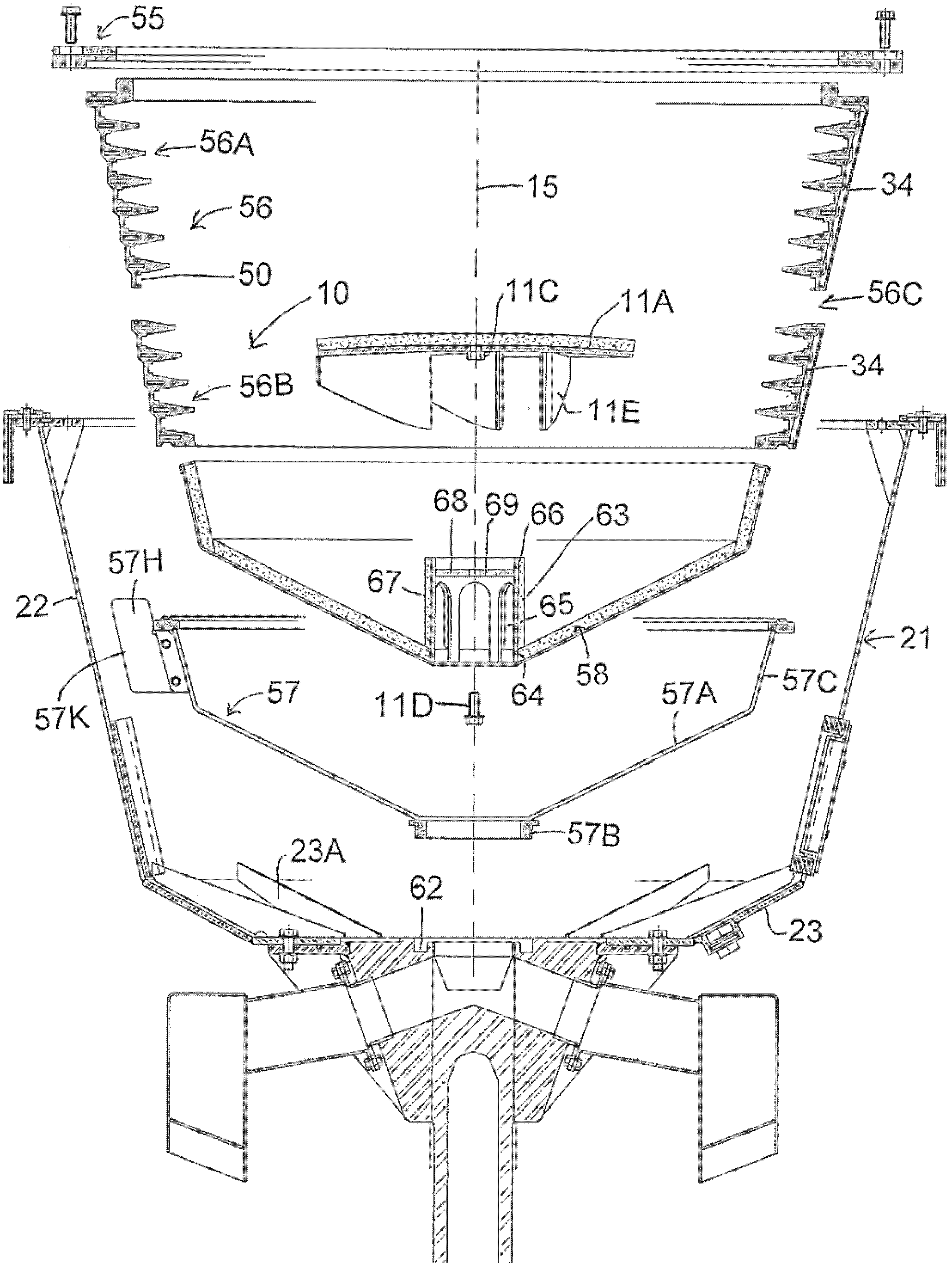

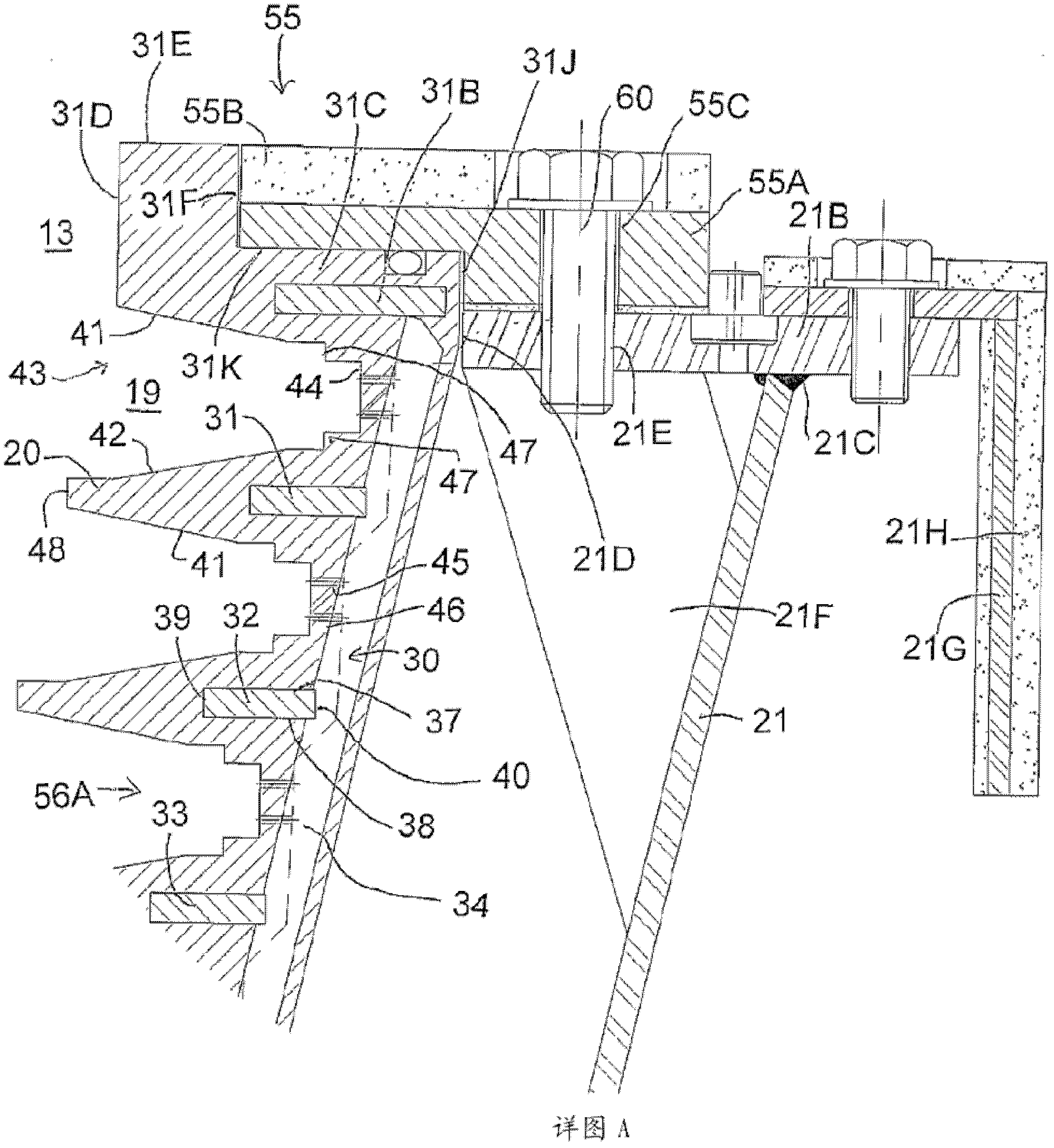

[0061] For example in the aforementioned US Patent 5,222,933 figure 1 The general arrangement of a centrifugal separator is shown in , and will therefore only be briefly described with reference to important points. Reference is made to the disclosure of the above-mentioned patents of the present assignee for further details which may be necessary for a full understanding.

[0062] The device thus comprises a bowl generally indicated at 10 having a base generally indicated at 11 and a peripheral wall 12 standing upwards from said base to an open mouth 13 . The bowl is rotatable about an axis 15 on a support shaft 16 .

[0063] The feed pipe carries the feed material in the form of a mixture of heavier and lighter particulate materials in a slurry to a position adjacent the bottom 11 through the open mouth 13 so that the feed material can be deposited to a horizontal deflector pad at the bottom 11 (deflector pad) 11A and can move from it to the peripheral wall 12 to separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com