A detection method for automobile girder plate

A detection method and beam-slab technology, applied in the direction of applying stable tension/pressure to test material strength, test metal, material inspection products, etc., can solve the problem that the yield strength cannot be detected, there is no test method, and the tensile test results are difficult to obtain Conclusions and other issues to achieve a good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

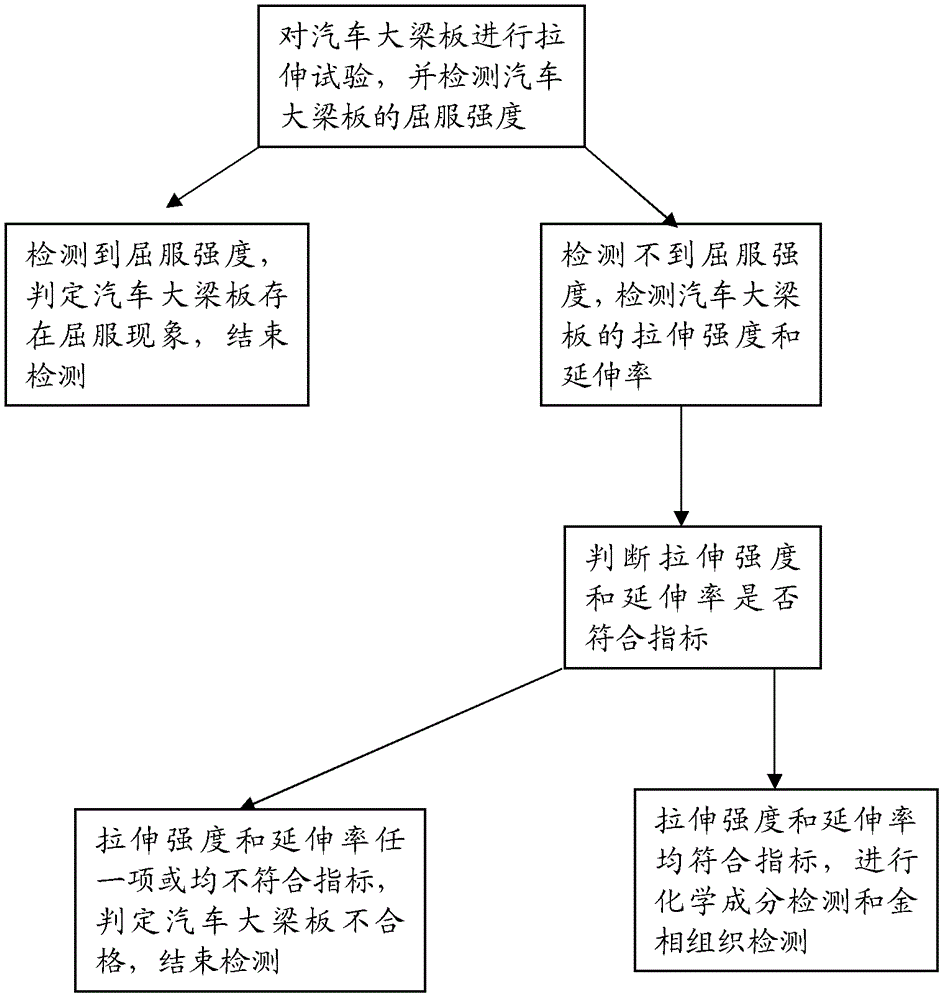

Method used

Image

Examples

Embodiment 1

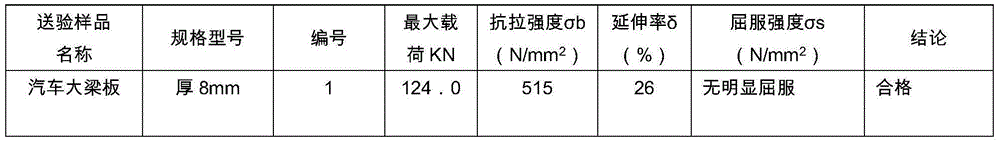

[0031] Randomly select 7 cases of automobile girder plates for tensile test, respectively detect the yield strength of the automobile girder plates and record the detection data, if the yield strength is detected, it is determined that there is a yield phenomenon in the automobile girder plates, and the detection is terminated.

[0032] If the yield strength cannot be detected, test the tensile strength and elongation of the automobile girder plate, and record the test data. The test results are shown in Table 1.

[0033] The tensile strength and elongation of each example of the automobile frame plate are compared and judged with the first predetermined index and the second predetermined index, wherein, the first predetermined index is GB / T3273-2005 "Hot-rolled steel plates for automobile frame plates and The tensile strength index formulated in the "Steel Strip" standard is: the tensile strength σb is between 510-630 (N / mm 2 ) within the scope of conformity index; the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com