An automatic control method for preventing continuous casting mold from spilling steel

A continuous casting mold and mold technology, applied in the field of steel continuous casting, can solve the problems of unmanned casting, equipment burning and expansion, etc., to achieve advance prediction and automatic disposal, minimize accident losses, The effect of removing important constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

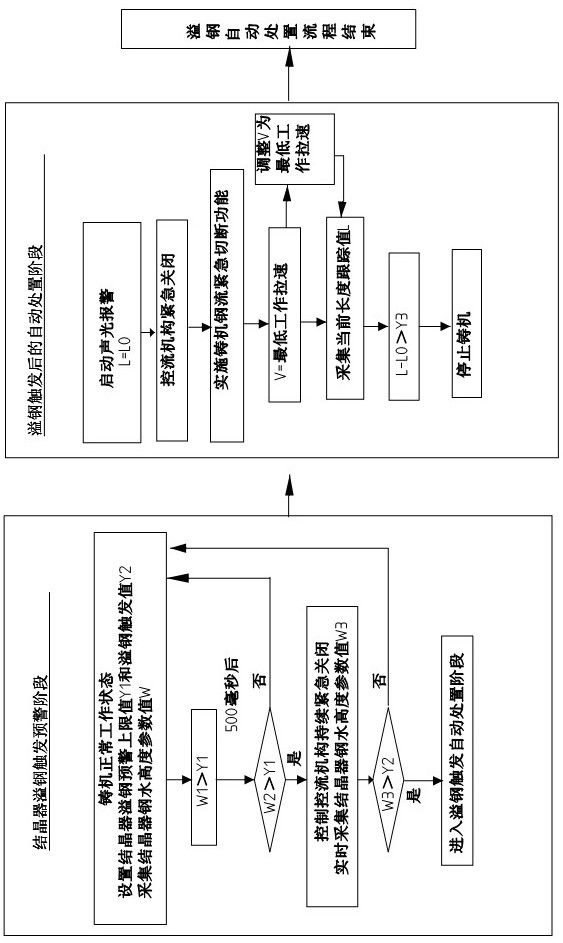

[0025] see figure 1 ,

[0026] In this example:

[0027] The mold length of the casting machine is 900mm, so the pre-set upper limit value Y1 of mold overflow steel is 860mm, and the trigger value Y2 of steel overflow is 880mm;

[0028] The molten steel flow control method of the crystallizer is stopper rod control flow plus blind plate emergency cut-off control method;

[0029] The allowable minimum casting speed value set by the process is 0.3m / min;

[0030] When the process is capped, the stop height in the crystallizer is 0.4m;

[0031] Take the above continuous casting machine parameters as an example:

[0032] An automatic control method for preventing continuous casting mold steel overflow, the method comprising:

[0033] 1. Mold overflow triggers early warning stage:

[0034] 1.1 Set the early warning upper limit value Y1=860mm and trigger value Y2=880mm of mold overflow steel

[0035] 1.2 Collect the parameter value W of the molten steel height of the mold, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com