Tightly sleeved optical cable and mold thereof

A technology of tight-buffered optical cable and tight-buffered optical fiber, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of signal feedback and only positioning of nodes, increased troubleshooting time, and unfavorable finding of fault points, etc., to achieve good tensile strength and reduce maintenance Cost, the effect of avoiding fiber cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

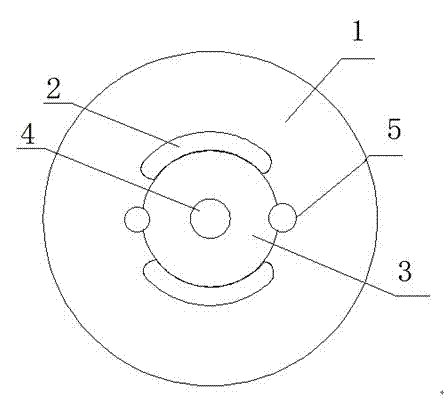

[0019] control figure 1 , the tight-buffered optical cable provided by the present invention includes an outer sheath 1, a strength member 2, an optical fiber 4, an inner sheath 3 and two copper wires 5, and the strength member 2 used in this embodiment is a sheet-shaped aramid ribbon, ensuring The tight-packed optical fiber 4 is small in size and light in weight. The inner sheath 3 is arranged at the central axial position of the outer sheath 1 , and the central axial position of the inner sheath 3 is provided with an optical fiber 4 . An aramid ribbon is arranged between the outer sheath 1 and the tight sleeve optical fiber 4 . The copper wires are evenly distributed on the inner circumference of the outer sheath 1 . The copper wire 5 is used as a feedback line, and one end of the copper wire 5 is connected to an alarm bell. The surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com