Fixing structure of battery module

A battery module and fixed structure technology, which is applied in the direction of secondary batteries, structural parts, battery temperature control, etc., can solve the problems of battery module cooling performance reduction and obstruction of refrigerant flow, etc., to ensure cooling performance and avoid large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

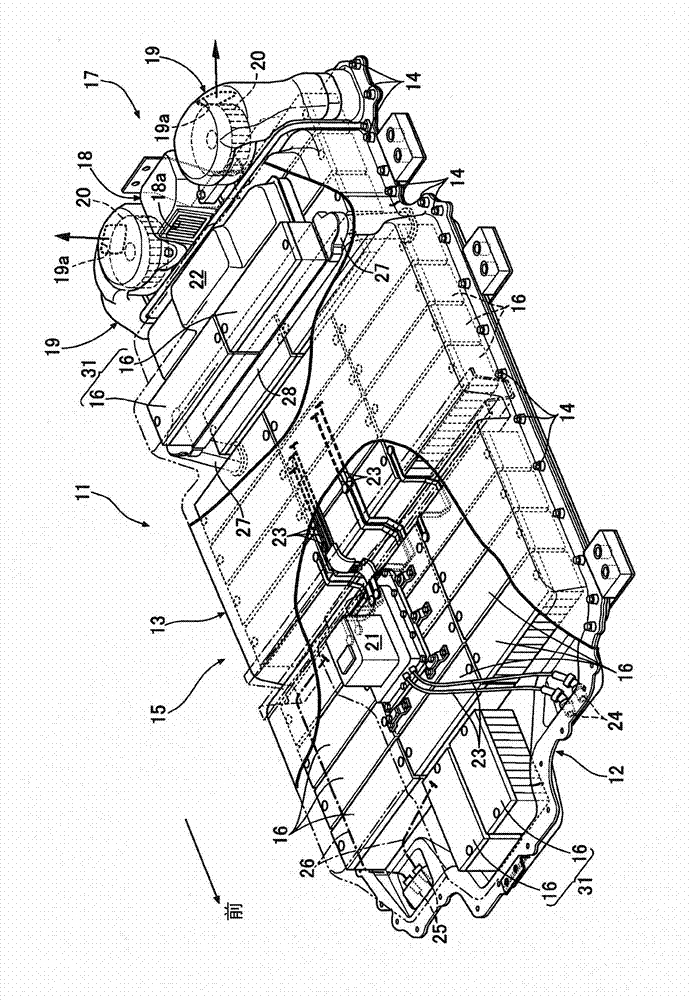

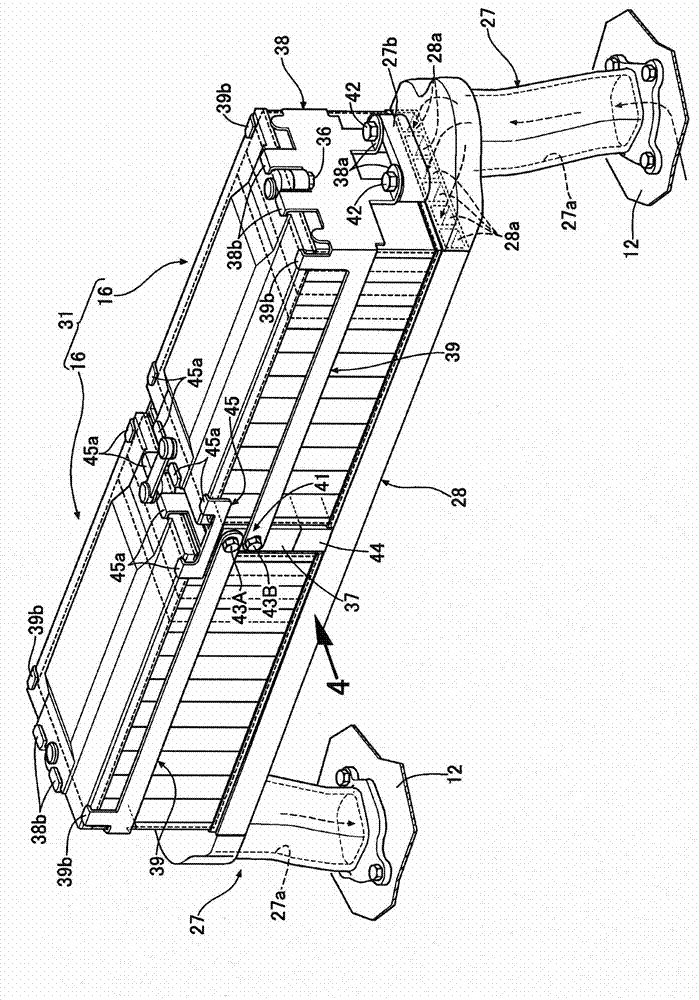

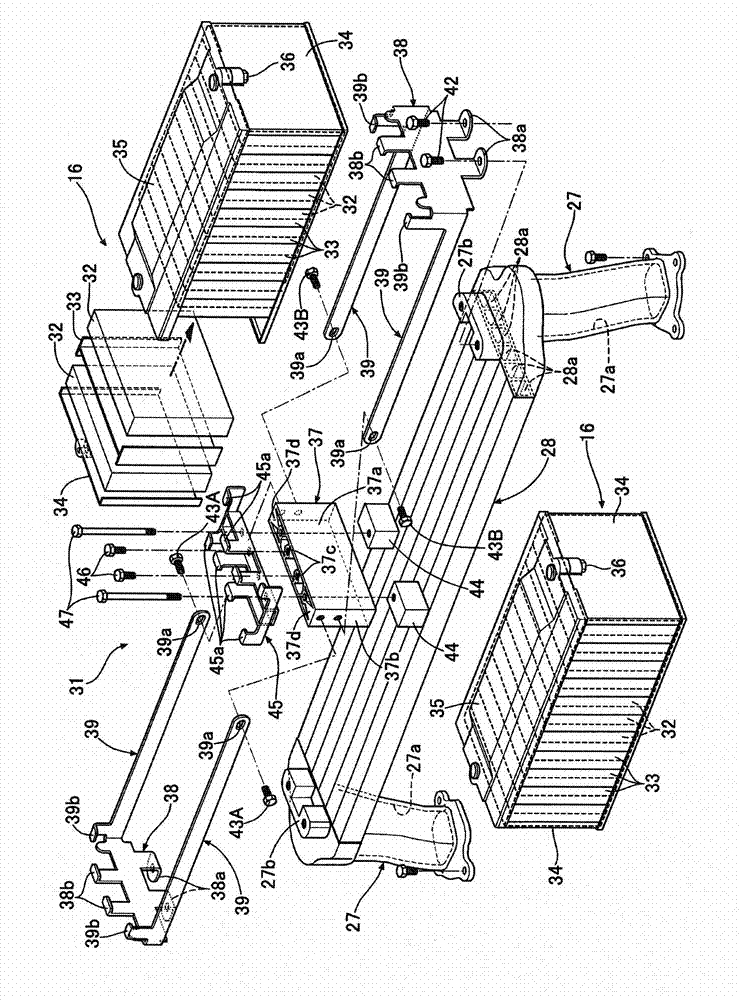

[0032] Below, according to Figure 1 to Figure 6 Embodiments of the present invention will be described.

[0033] Such as figure 1 As shown, the battery pack 11 of an electric vehicle is equipped with a battery case 15 in which a synthetic resin battery cover 13 is combined with a synthetic resin battery cover 13 on the upper surface of a metal battery tray 12 and fastened and connected by bolts 14 . . . A plurality of battery modules 16 . . . are mounted on the upper surface.

[0034] The cooling device 17 provided at the rear of the battery pack 11 includes a suction duct 18 disposed in the center in the vehicle width direction, and a pair of left and right discharge ducts 19 disposed on both sides of the suction duct 18 in the vehicle width direction. A cooling air inlet 18 a is opened forward on the upper front surface of the suction passage 18 , and the cooling air inlet 18 a is used to suck air outside the battery pack 11 into the inside as cooling air. In addition, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com