Electrical equipment wire via hole waterproof sealing structure and waterproof sealing method

A waterproof sealing and wire technology, applied in circuit/collector parts, circuits, electrical components, etc., can solve problems such as poor ease of use, and achieve the effect of good convenience and large opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

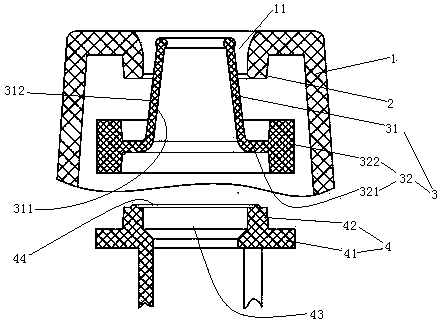

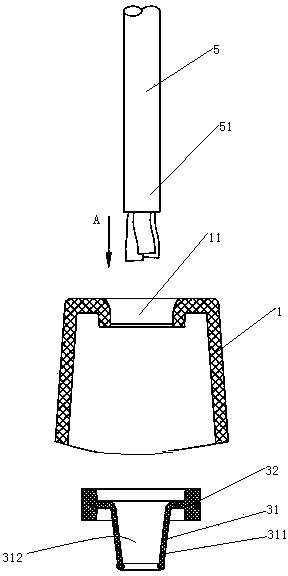

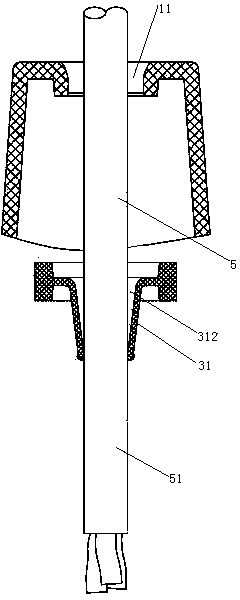

[0028] see figure 1 , a waterproof sealing structure for electric wire through holes, comprising a through-hole inner flange 2 , a sealing member 3 and a pressing frame 4 arranged on an electric wire through hole 11 of an electric appliance 1 .

[0029] The seal 3 is made of elastic material. The seal 3 includes an elastic sealing sleeve 31 and a base ring 32 . The base ring 32 and the elastic sealing sleeve 31 are integrally structured. The elastic sealing sleeve 31 is a reversible structure. The elastic sealing sleeve 32 extends toward the outside of the electrical appliance 1 . The inner surface 311 of the elastic sealing sleeve is a conical surface. The outer surface 312 of the elastic sealing sleeve is a conical surface. The outer radius of the lower end of the elastic sealing sleeve 31 is large, and the outer radius of the upper end is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com