Electropneumatic converter with low hysteresis

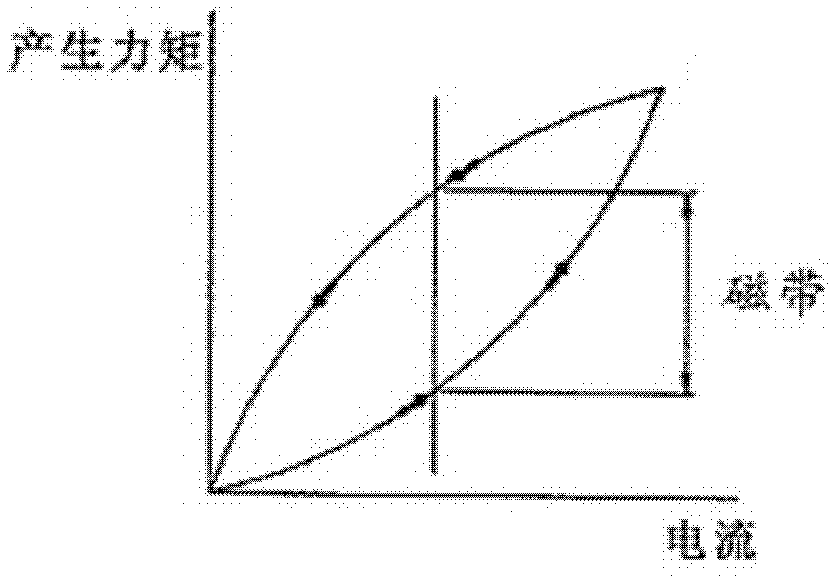

A converter, electro-dynamic technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problem that the electric-electric converter is difficult to adjust precisely, and achieve the effect of low hysteresis characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

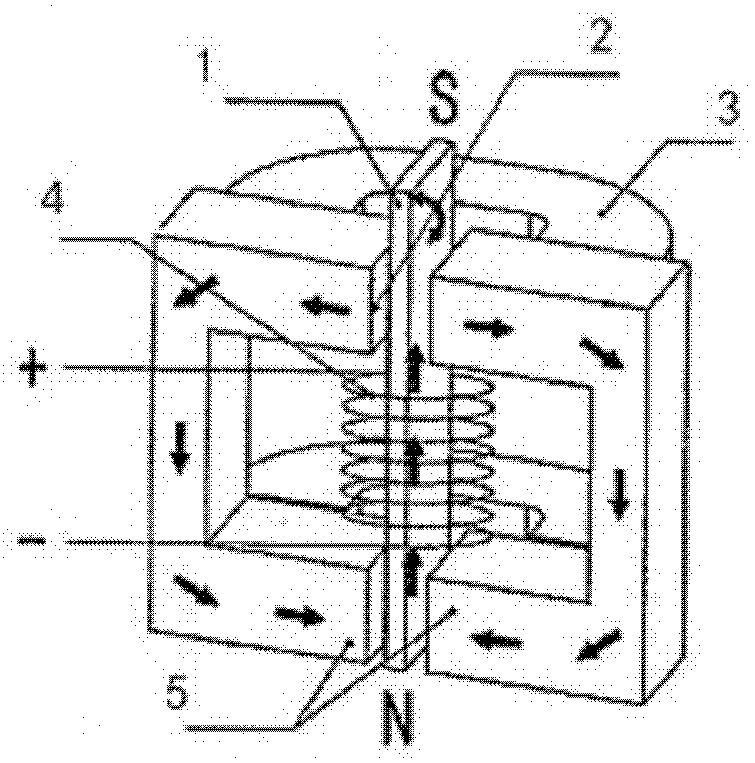

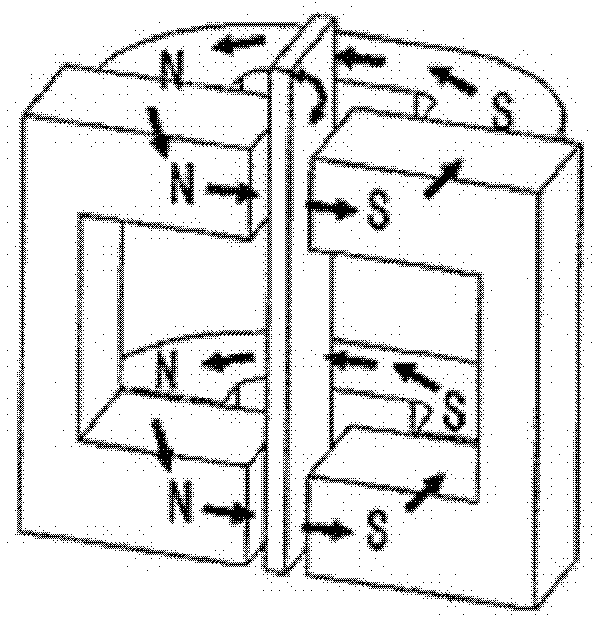

[0024] Figure 3a and 3b An electropneumatic converter 100 according to an embodiment of the invention is shown. Figure 3a showing the closed magnetic circuit formed by the magnetic field generated by the coil, Figure 3b Shows a closed magnetic circuit formed by a magnetic field generated by a permanent magnet.

[0025] The electro-pneumatic converter 100 according to this embodiment includes a first stator 110 , a first stator gap 112 , a coil 114 , a second stator 120 , a second stator gap 122 , a permanent magnet 124 and a moving part 130 .

[0026] A first stator gap 112 is formed at one end of the first stator 110 , and a coil 114 is wound around a part thereof. The first stator 110 is made of a material with low saturation magnetic flux density and low coercive force. For example, the first stator 110 may be made of PC (permalloy with a nickel content of 78%). Additionally, the first stator 110 may be made of a single or multiple materials.

[0027] One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com