Patents

Literature

45results about "Converting sensor output using fluid means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic Sensor and Electronic Cigarette

InactiveUS20170219391A1Simple manufacturing processEasy to driveVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityEngineering

The present invention discloses a pneumatic sensor, having an air intake and an air outlet. The pneumatic sensor includes a first triboelectric component, a shell, a second triboelectric component and a third triboelectric component, wherein the shell has a hollow structure in a preset shape to form an airflow channel, and the airflow channel is communicated with the air intake and the air outlet, thus allowing the airflow to enter the airflow channel from the air intake and flow out from the air outlet; the first triboelectric component is arranged in the airflow channel, and the second and the third triboelectric components are arranged at positions capable of contacting with the first triboelectric component; and the second and the third triboelectric components include electric signal output terminals of the pneumatic sensor.

Owner:NAZHIYUAN TECH TANGSHAN LLC

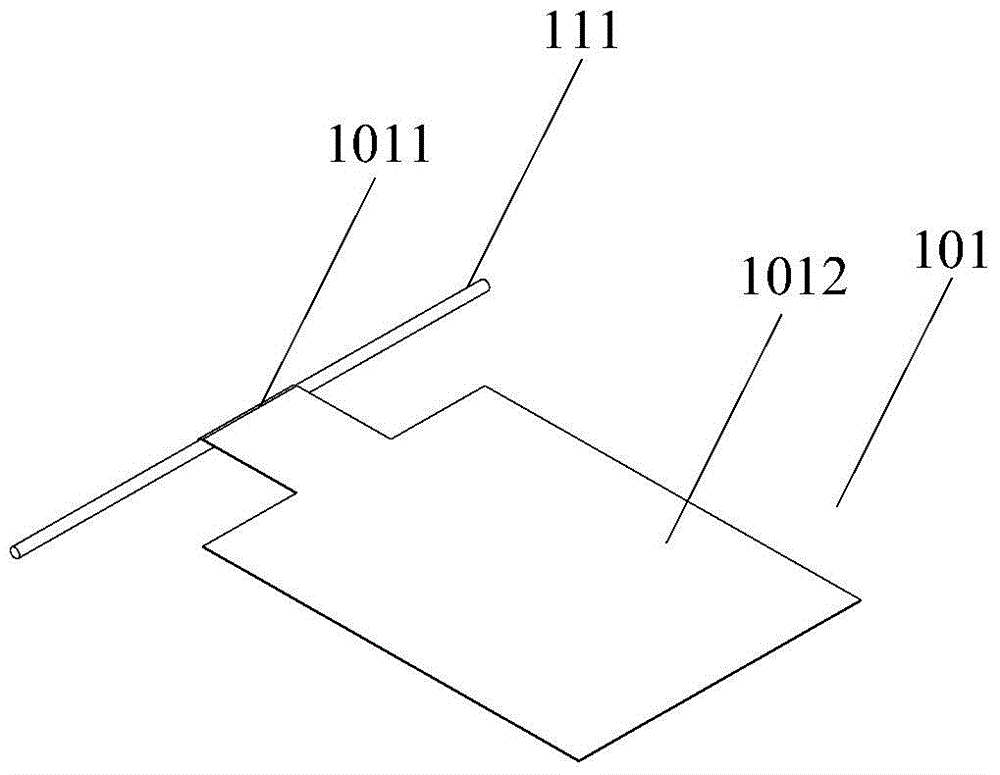

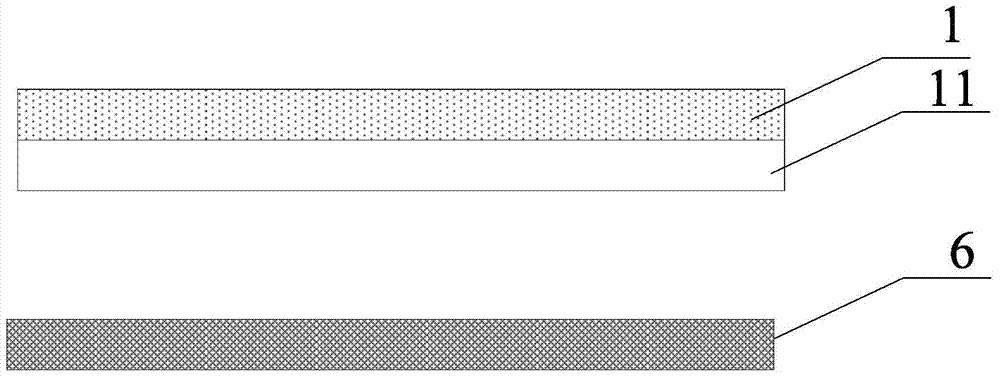

Liquid metal-based flexible sensing device

InactiveCN107870004AImprove flexibilityThe test result is accurateConverting sensor output using fluid meansLiquid stateLiquid metal

The invention provides a liquid metal-based flexible sensing device. The flexible sensing device comprises a flexible substrate, an outer flexible base material located on the flexible substrate, anda flexible sensor located in the outer flexible base material and based on liquid metal. The liquid metal-based flexible sensor is connected with external detection equipment through a lead so as to realize the sensing detection. The liquid metal-based flexible sensing device can improve the detection precision of the flexible sensing device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

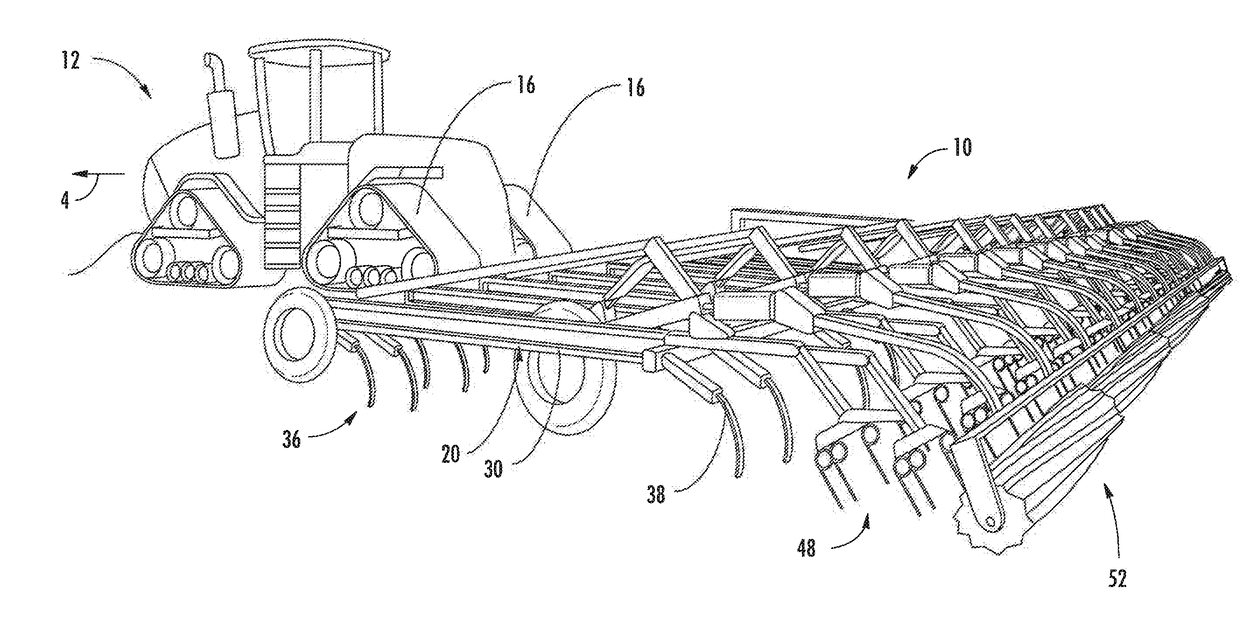

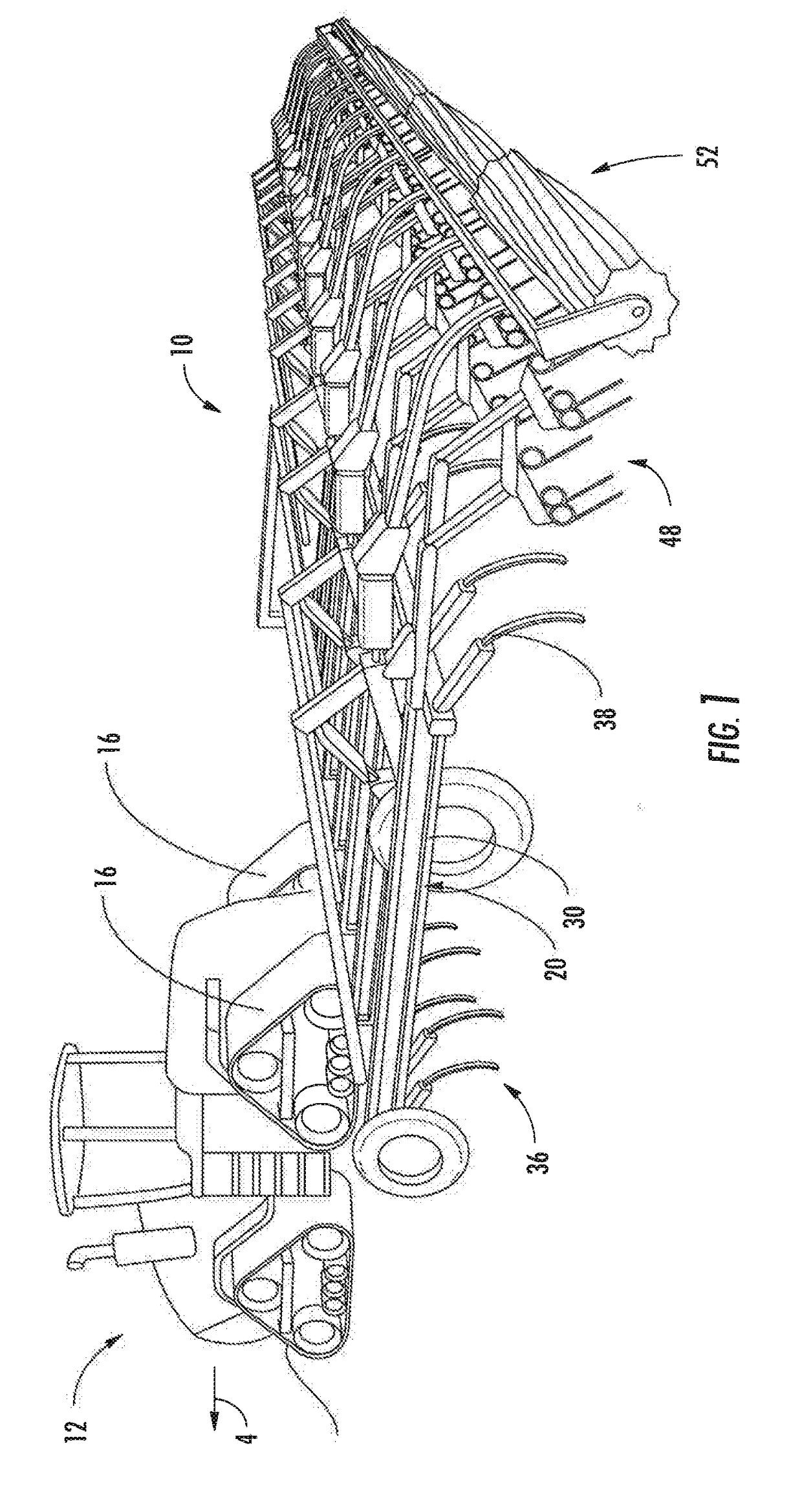

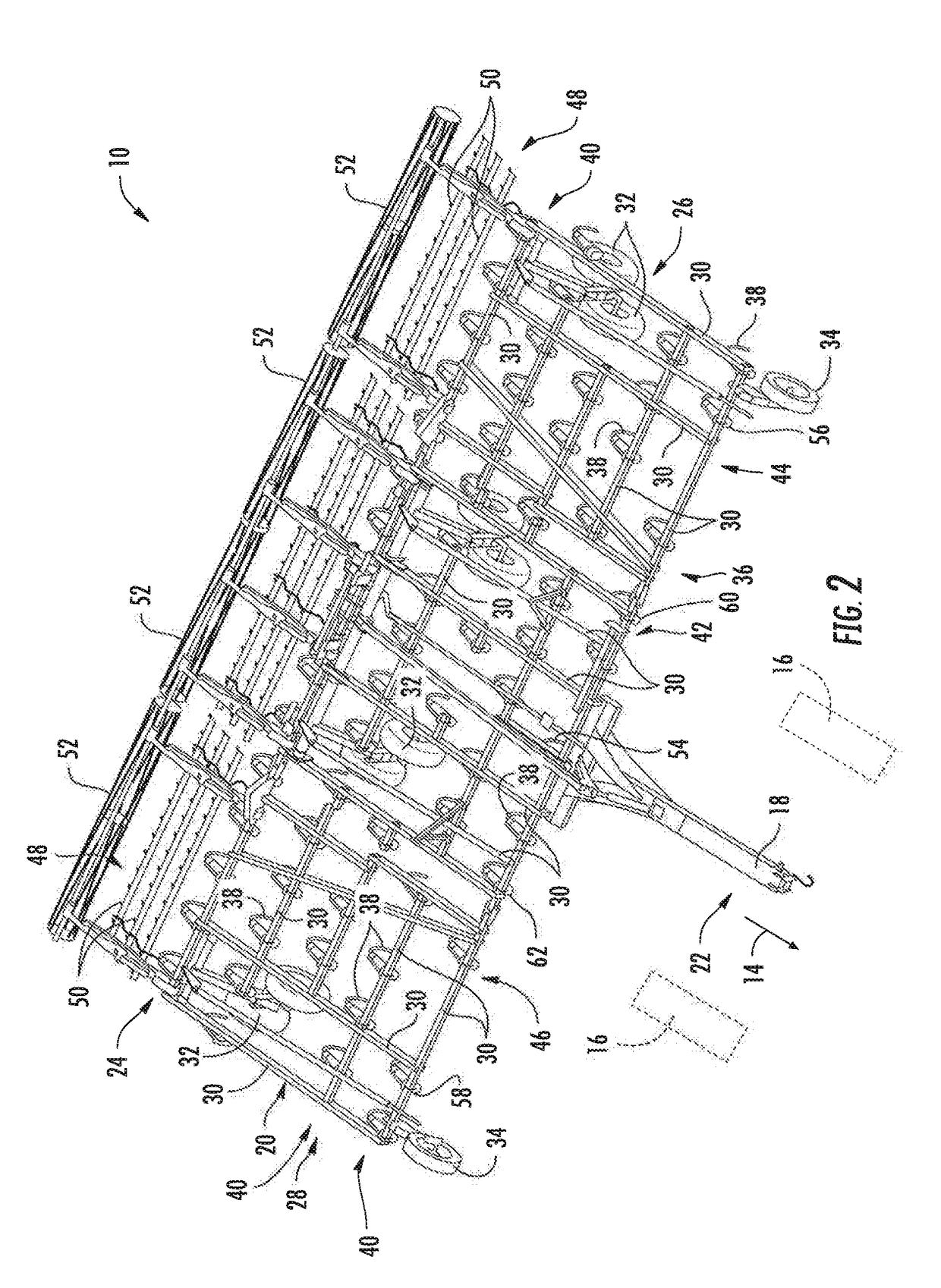

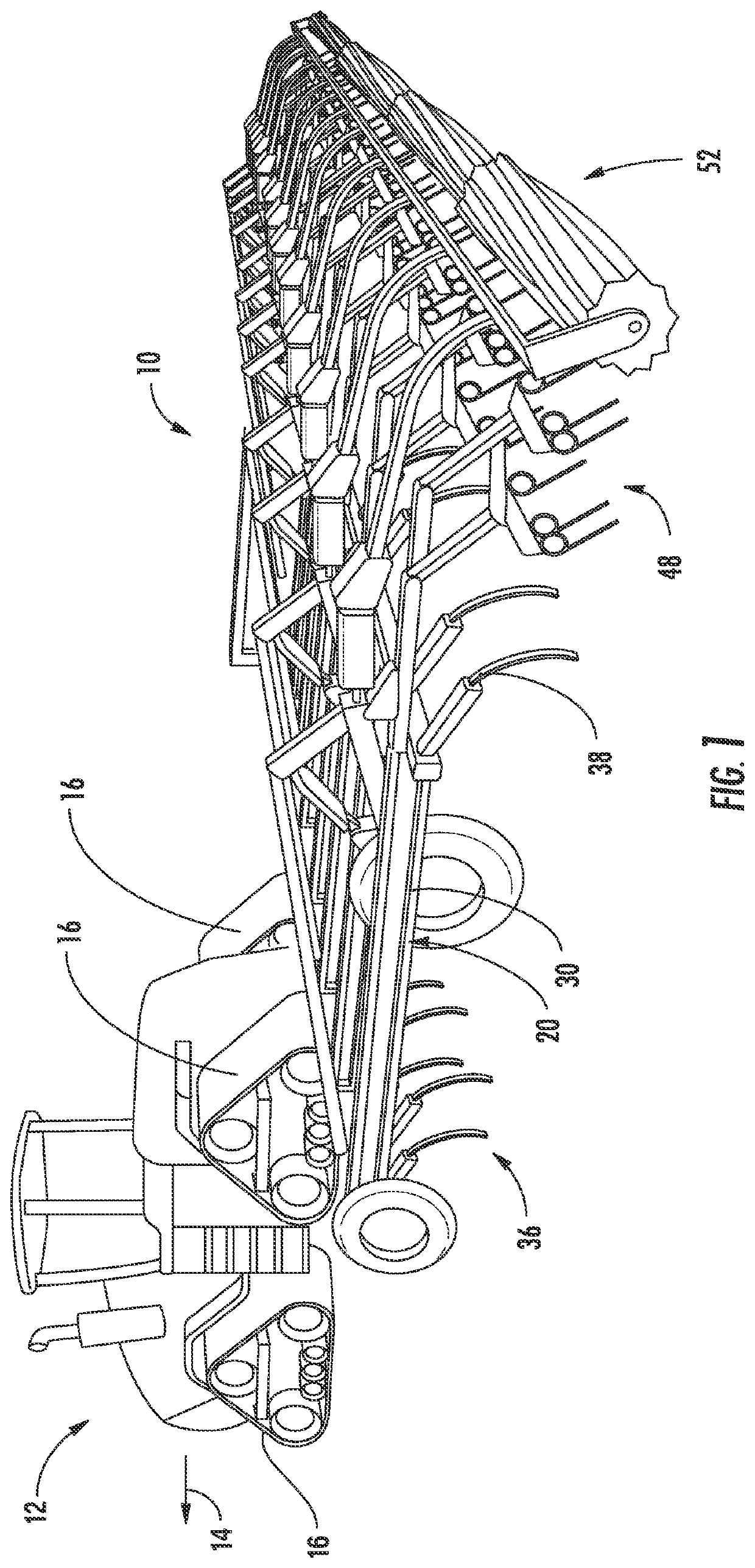

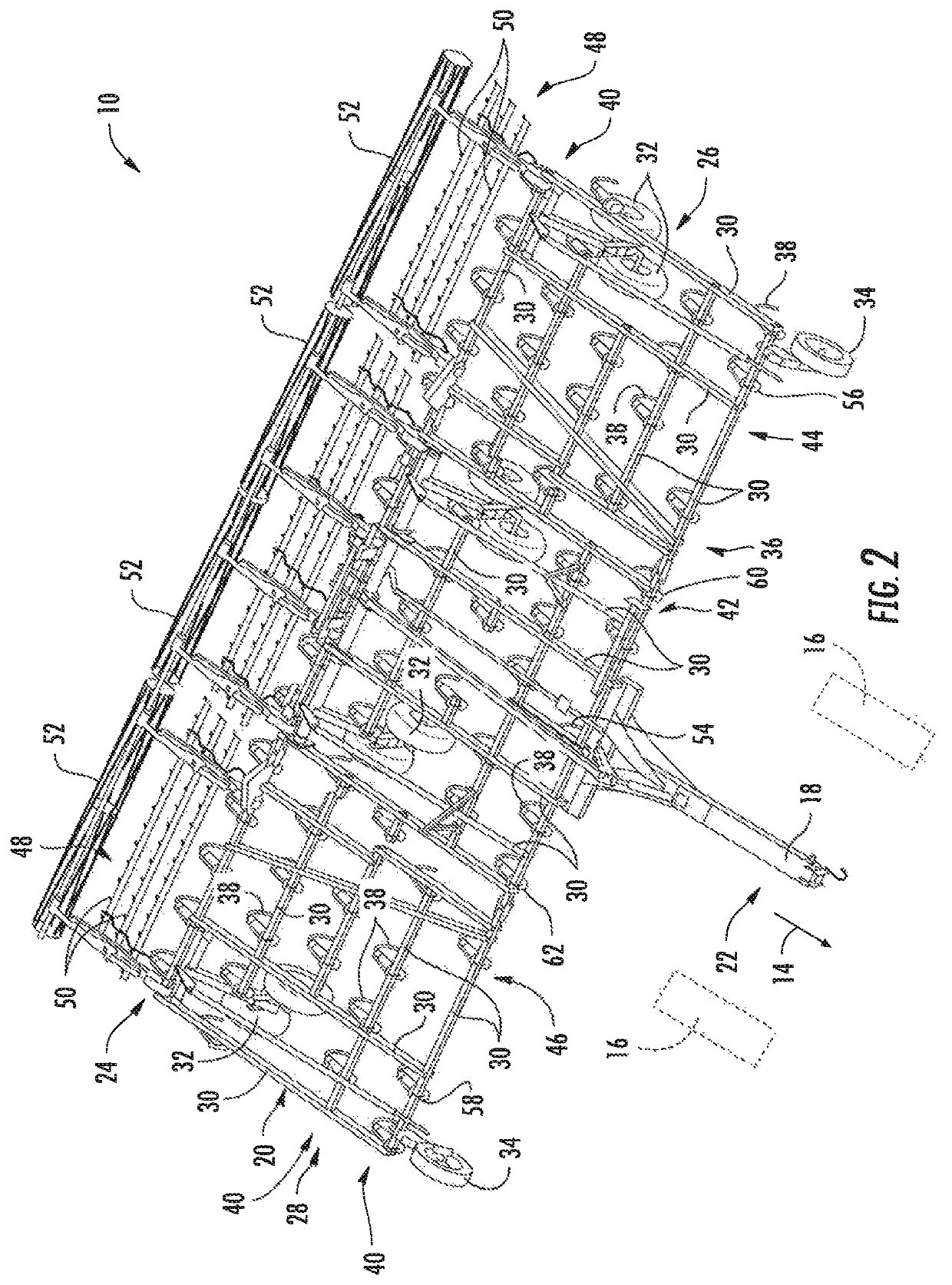

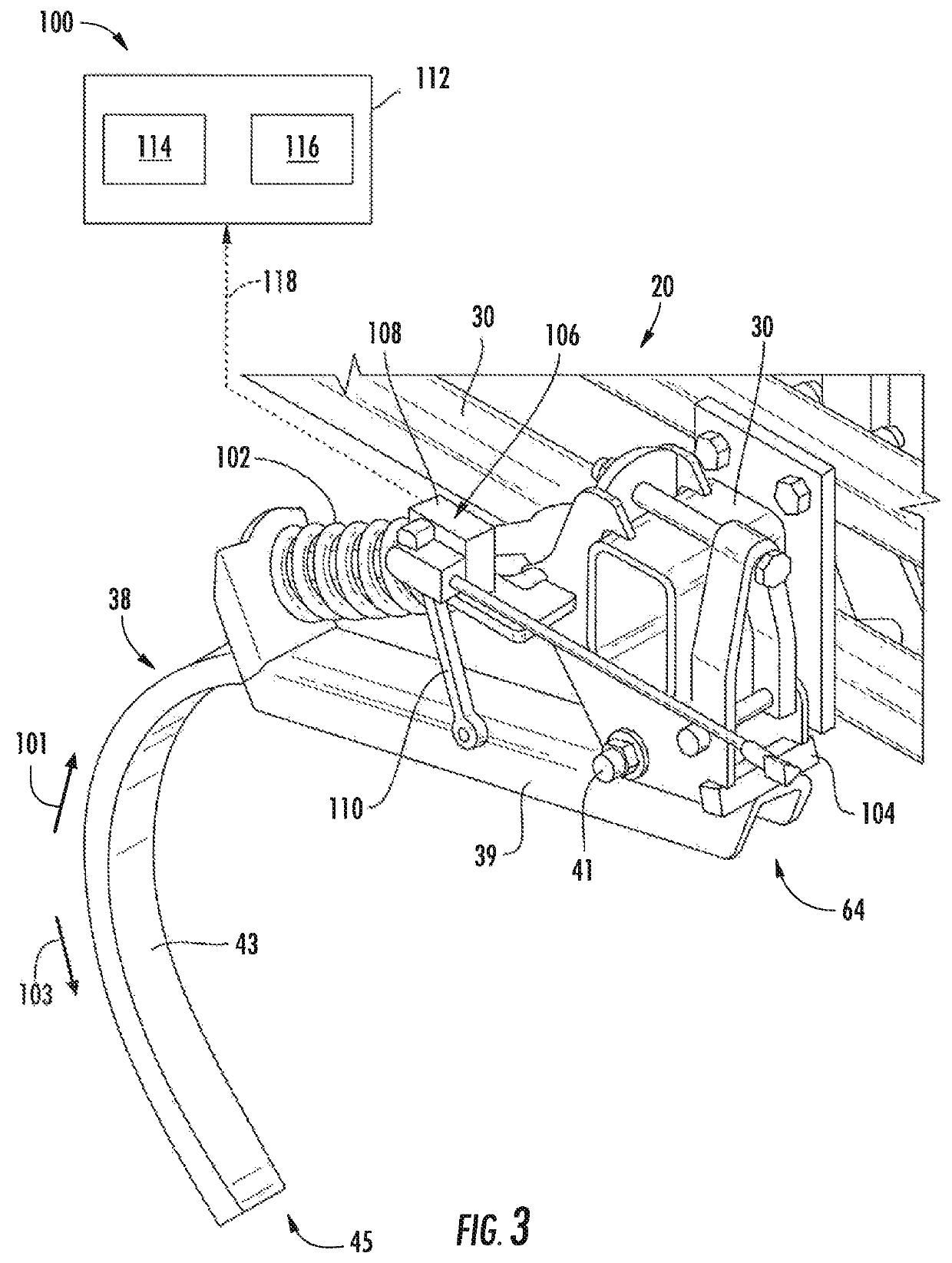

System and method for detecting ground engaging tool float for an agricultural implement

In one aspect, a system for detecting ground engaging tool float for an agricultural implement may include an implement having a ground engaging tool pivotally coupled to a frame and a biasing element coupled between the frame and the ground engaging tool. The biasing element may be configured to bias the ground engaging tool to a predetermined ground engaging tool position relative to the frame. The system may also include a sensor configured to detect a parameter indicative of a current position of the ground engaging tool relative to the frame. Additionally, the system may include a controller configured to monitor the current position of the ground engaging tool based on measurement signals received from the sensor and identify a time period across which the ground engaging tool is displaced from the predetermined ground engaging tool position. The controller may be further configured to compare the identified time period to a threshold time period to determine when a ground engaging tool float event is occurring during operation of the implement.

Owner:INC BLUE LEAF I

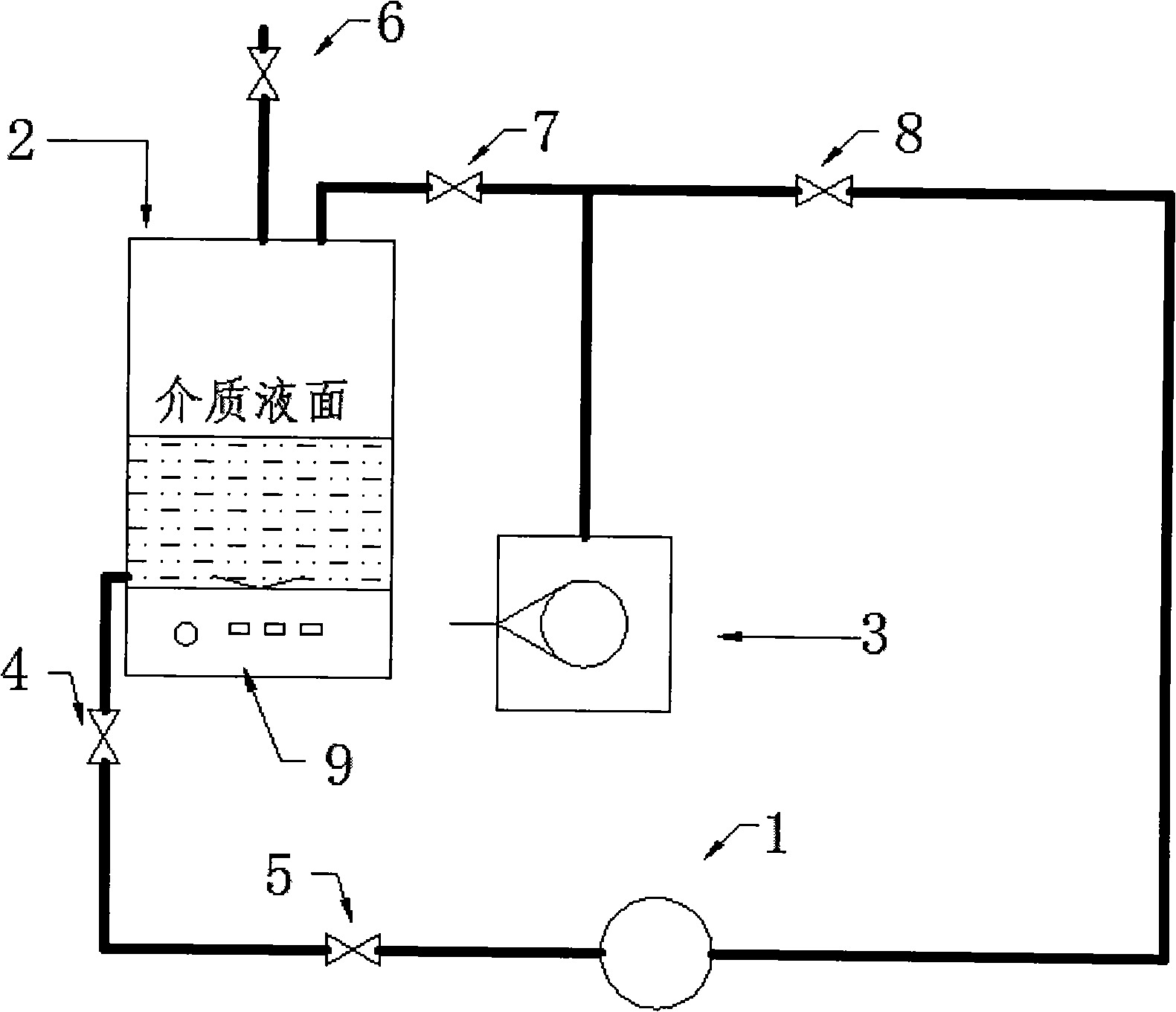

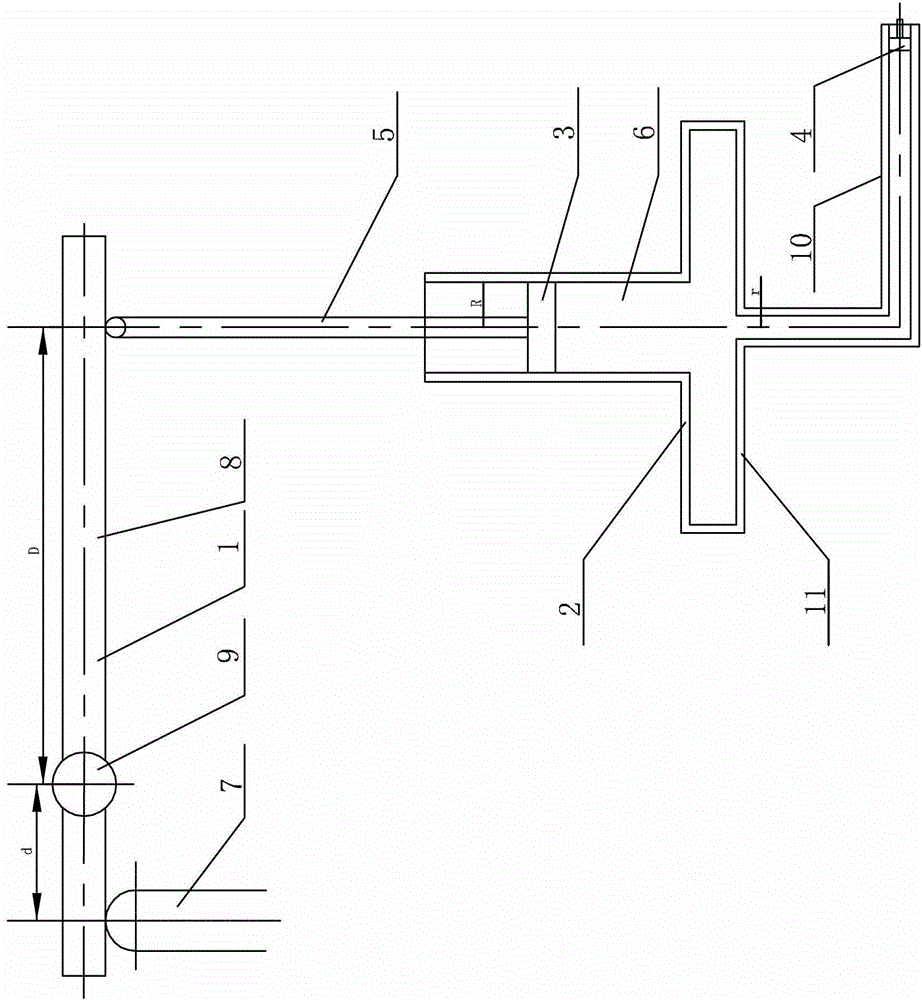

Filling and pouring method of intelligent transmitter to measure bellows pressure transmission medium

InactiveCN101281044AIncrease pressureQuick pressConverting sensor output using fluid meansPressure transmissionTransducer

The invention relates to a filling method for an intelligent transducer measuring film box pressure conductive medium, which comprises following steps: (1) enabling the intelligent conductive flange 1) in a vacuum state; (2) purifying the conductive medium; (3) opening the oil check valve 4), oil charging valve 5) to make the conductive medium get through the oil check valve 4), oil charging valve 5) to be filled to the intelligent conductive flange 1); (4) opening the gas discharging valve 6) at the top of the oil tank 2) for pressing the conductive medium to the intelligent conductive flange 1). The invention has the characteristic of assuring the purity of the conductive medium at the same time of enhancing the working efficiency.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

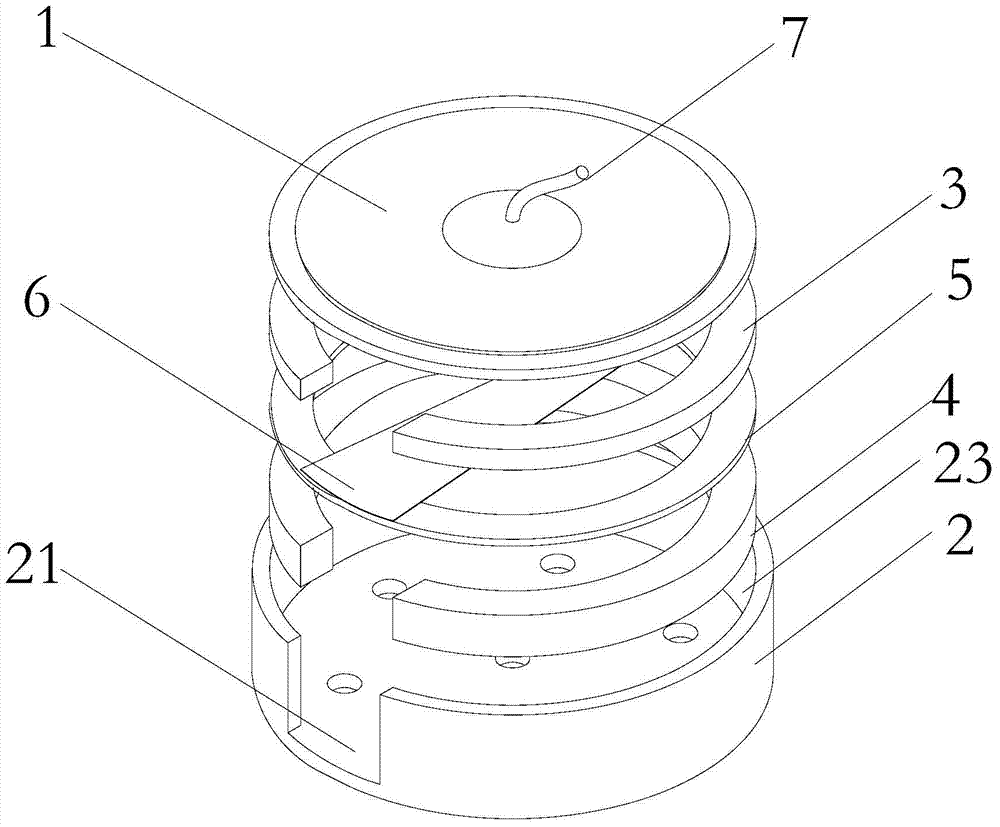

Pneumatic sensor

ActiveCN104807486AReduce manufacturing costLarge output signalConverting sensor output using fluid meansSignal processing circuitsEngineering

The invention discloses a pneumatic sensor, which comprises a shielding shell, an insulating layer arranged at part or all of the inner side surface of the shielding shell and at least one sensing unit, wherein the shielding shell is provided with at least two air vents, and an air flow passes through a part between the air vents; the sensing unit comprises at least one fixed layer and a free layer; the at least one fixed layer is fixedly arranged on the shielding layer; the free layer is provided with a fixed portion and a friction portion; the fixed portion of the free layer is fixedly connected with the at least one fixed layer or the shielding shell; the free layer is in friction with the at least one fixed layer and / or the shielding shell through the friction portion; and the at least one fixed layer and / or the shielding layer are / is a signal output end of the pneumatic sensor. The pneumatic sensor is low in manufacturing cost, great in output signal, low in requirement for an external signal processing circuit and reduces interference imposed on the pneumatic sensor by external vibration.

Owner:NEWNAGY TANGSHAN

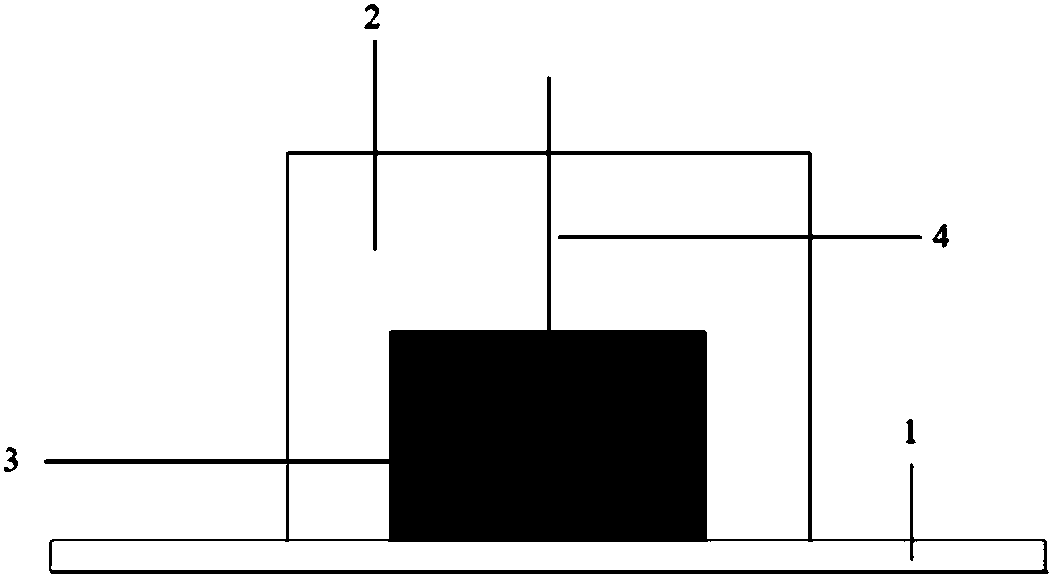

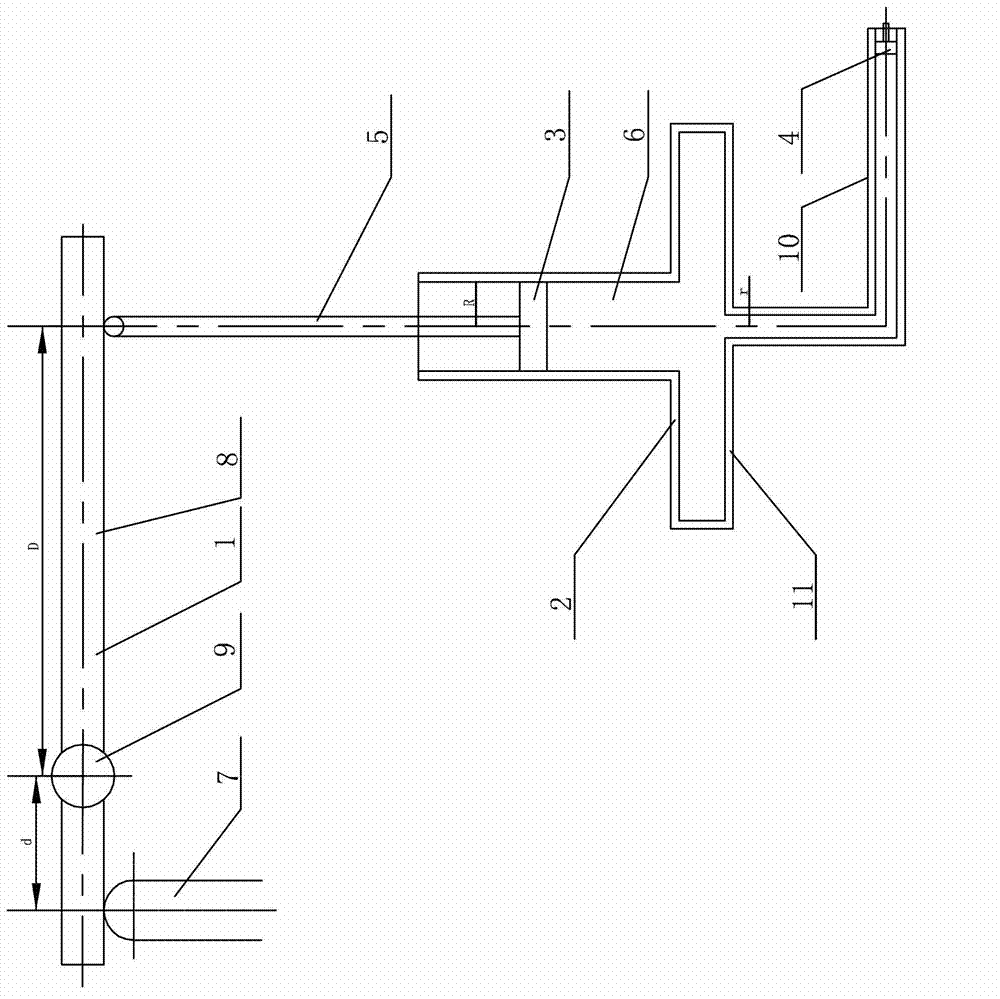

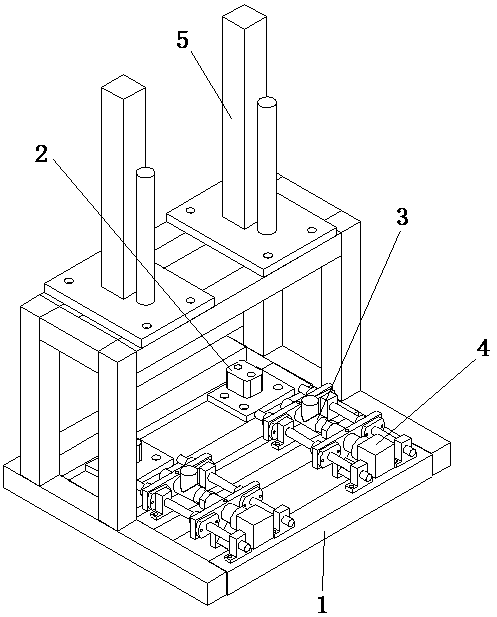

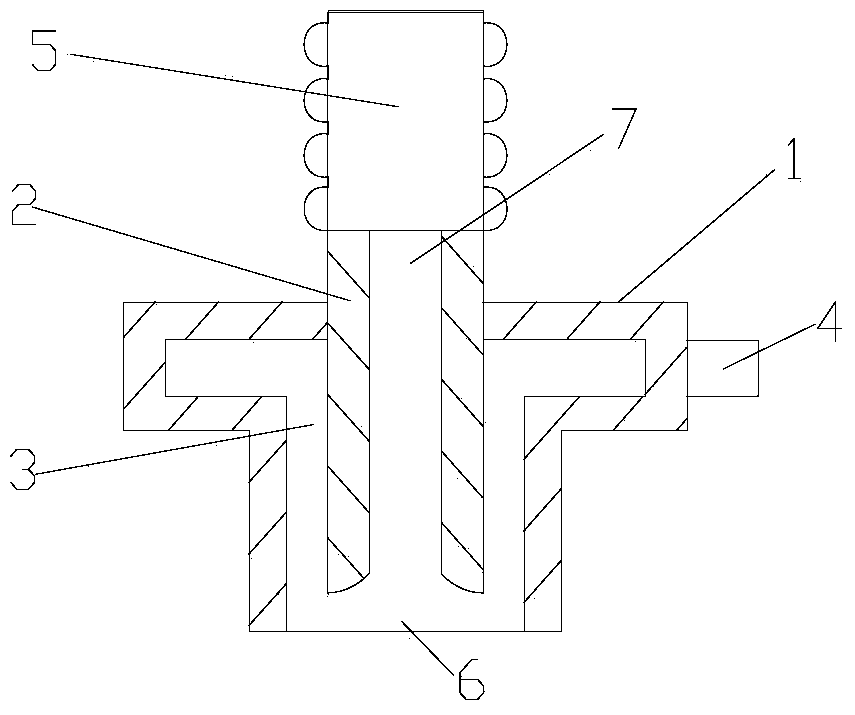

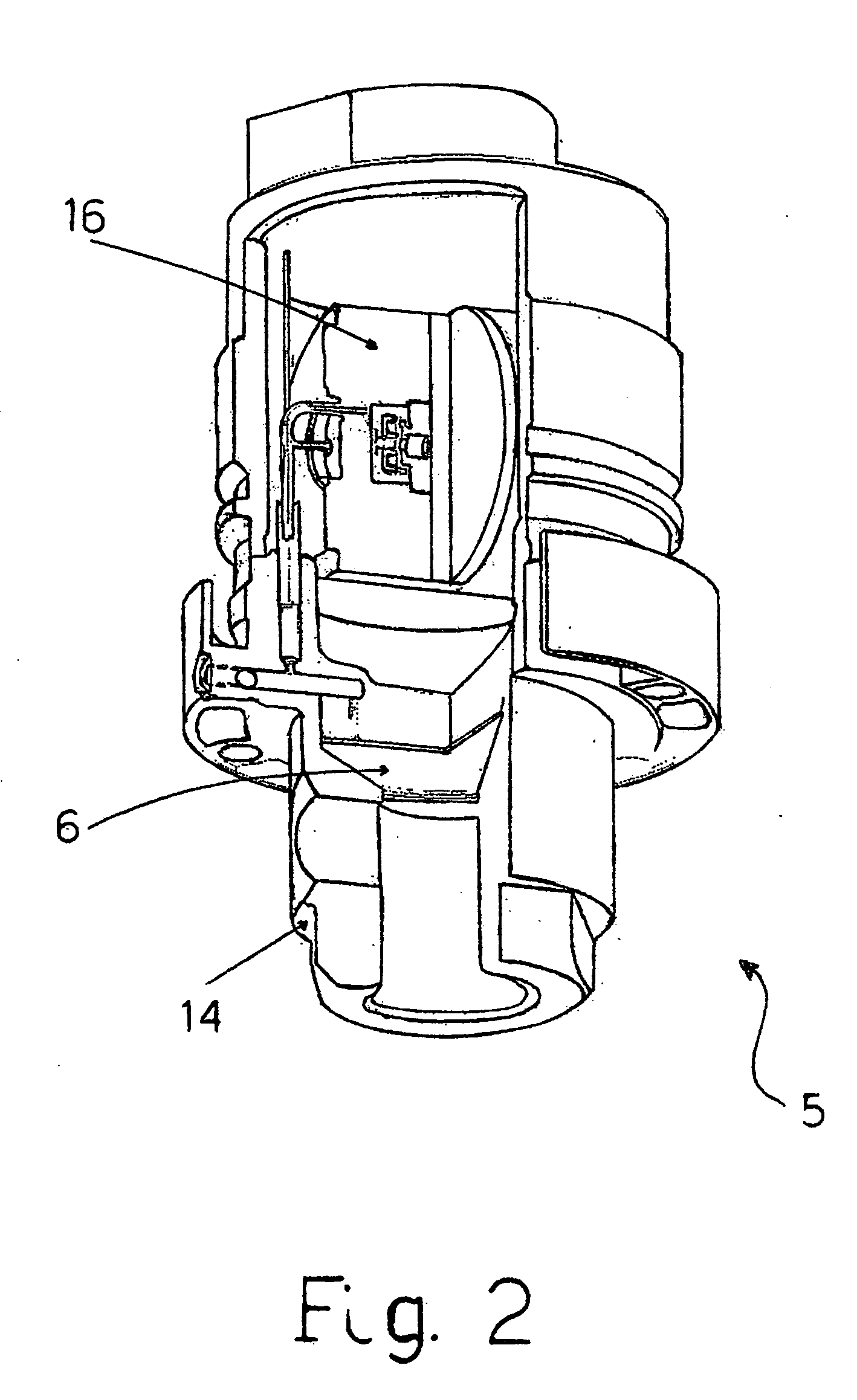

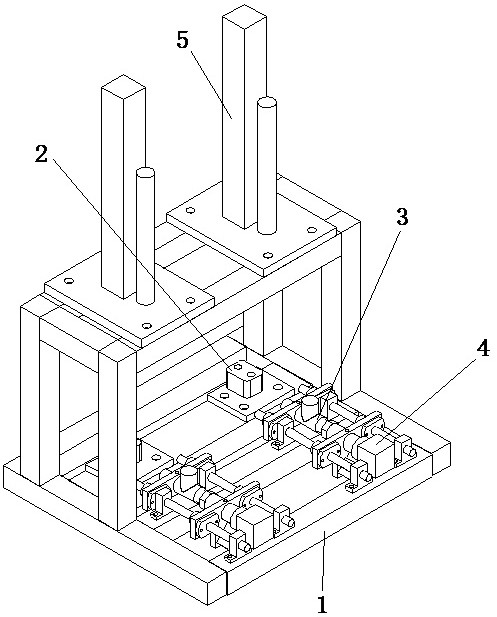

Displacement amplification device

InactiveCN103196476ASimple structureLow costConverting sensor output using fluid meansHydraulic cylinderEngineering

The invention relates to a displacement amplification device, and aims at resolving the problems that a device in the prior art is complex in structure and high in cost, and occupied installation space by a displacement amplification mechanism and other devices is large. The displacement amplification device comprises a lever structure and a hydraulic cylinder mechanism, wherein the lever structure comprises an ejection column, a lever and a support shaft; and the hydraulic cylinder mechanism comprises a first piston, a second piston, a connecting rod, hydraulic oil, a hydraulic cylinder and an oil outlet tube. The lever penetrates through the support shaft, the axis of the lever is vertical to the axis of the support shaft, the upper end of the ejection column is arranged below the left end of the lever, one end of the oil outlet tube is communicated with the middle portion of the lower end face of the hydraulic cylinder in a sealed mode, the lower end of the connecting rod is fixedly connected with the upper end face of the first piston, the first piston is arranged in a cylinder body of the hydraulic cylinder, the upper end of the connecting rod is arranged below the right end of the lever, the second piston is arranged in the other end of the oil outlet tube, and hydraulic oil is filled both in the hydraulic cylinder and the oil outlet tube. The displacement amplification device is used in the field of mechanical tools.

Owner:HARBIN INST OF TECH

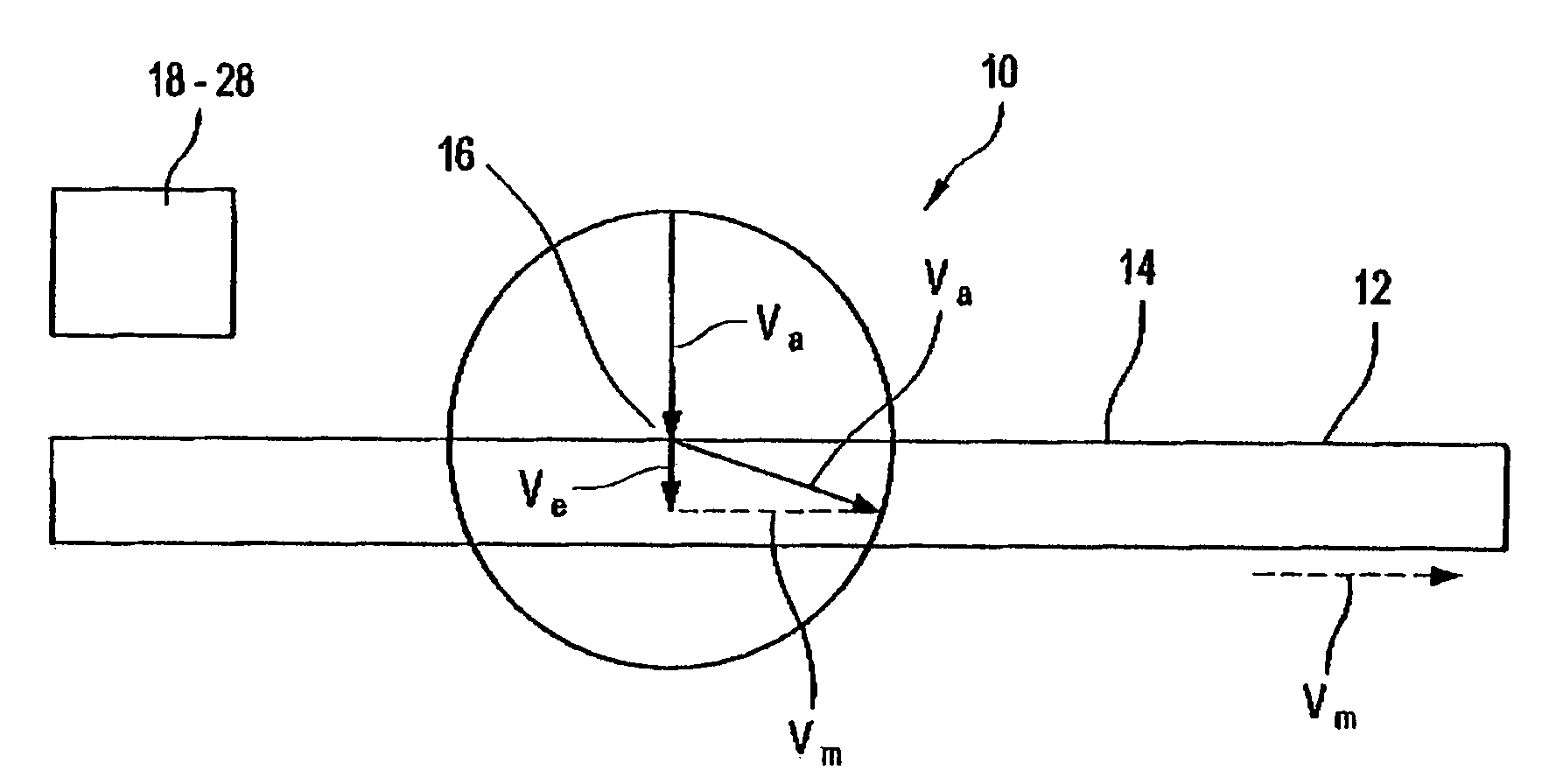

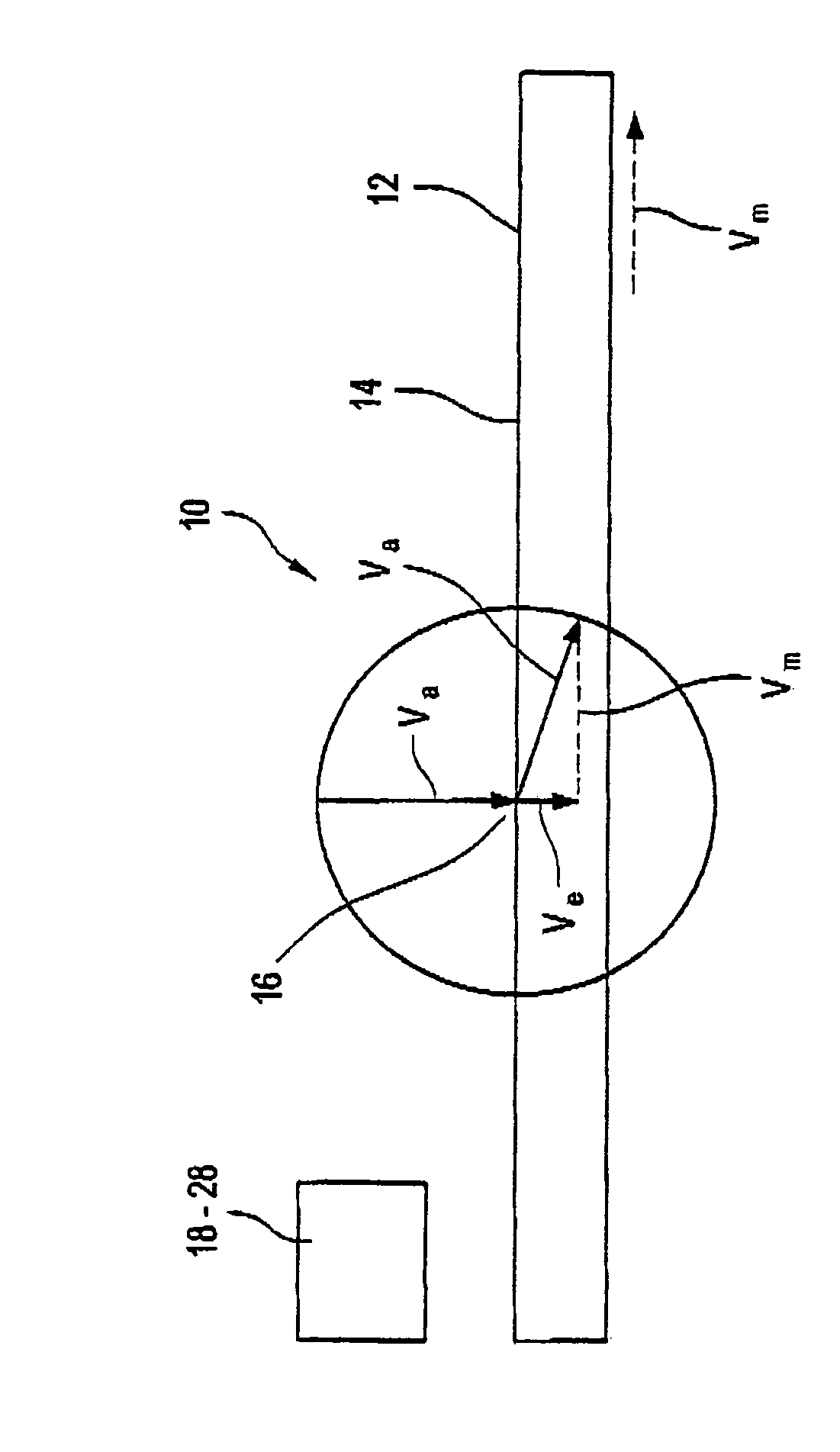

Method and apparatus for determining at least one property of moving clothing in a paper machine

InactiveUS6971261B2Extended service lifeUnplanned stoppages of the papermaking machine are avoidedConverting sensor output using fluid meansPaper testingCardboardInjector

A method of determining at least one property of moving clothing of a machine for producing and / or treating a material web, in particular a paper or board web, which includes the following steps: arranging a nozzle opposite the surface of the moving clothing; producing a jet acting on the clothing by way of the nozzle contacting the moving clothing; measuring a variable representative of the flow through the nozzle; measuring a variable representative of the pressure of the jet at the nozzle outlet; determining the speed of the jet at the nozzle outlet from the nozzle flow and the free surface of the jet medium at the point of contact with the clothing; and determining the speed of the jet at the entry into the clothing from the speed of the jet at the nozzle outlet and the speed of the clothing. By using the speed of the jet at the entry into the clothing at a given pressure of the jet at the nozzle outlet and entry into the clothing, the water permeability of the moving clothing is determined and / or at least one surface property of the moving clothing is determined. A corresponding apparatus is also specified.

Owner:VOITH PATENT GMBH

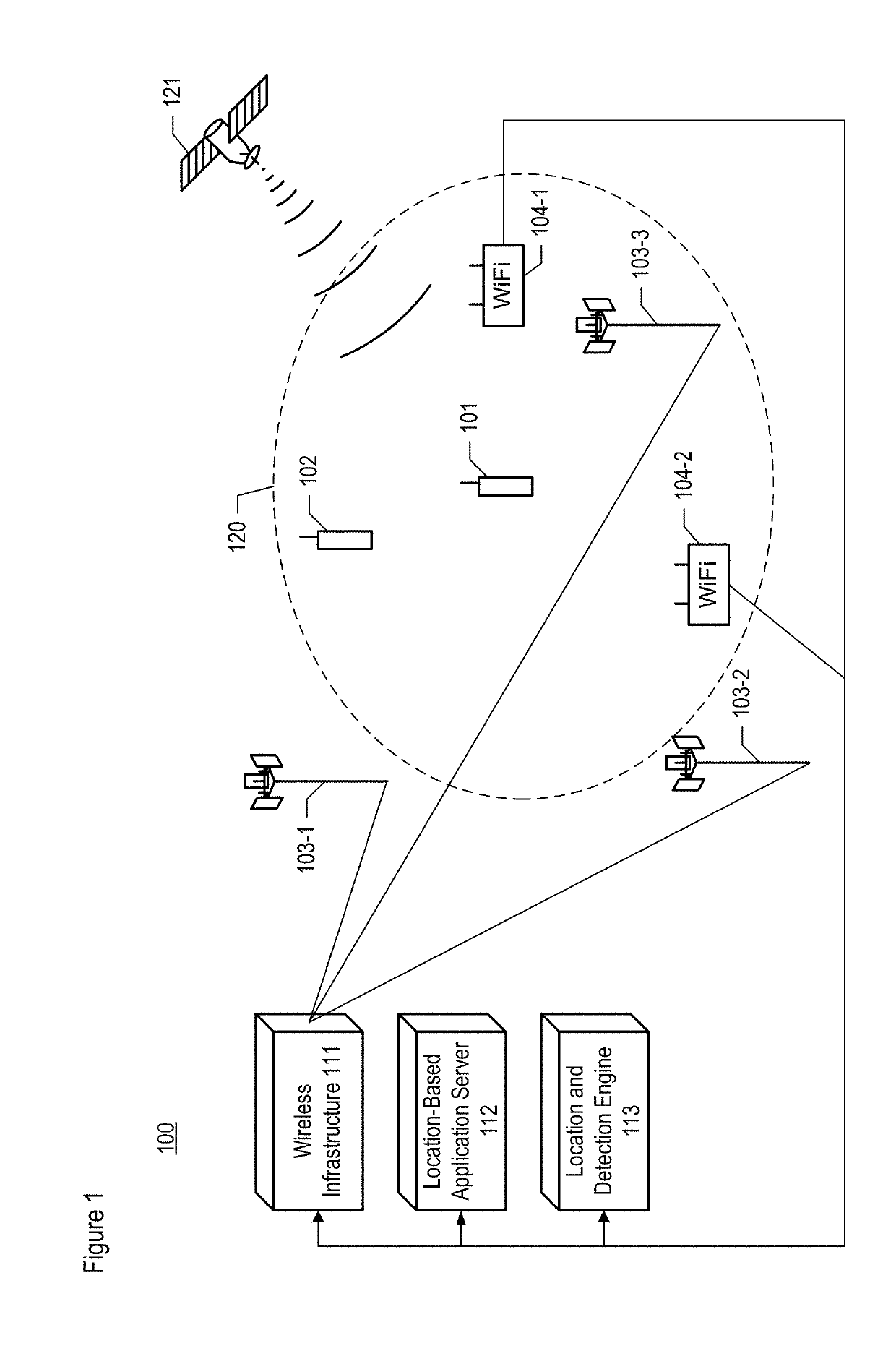

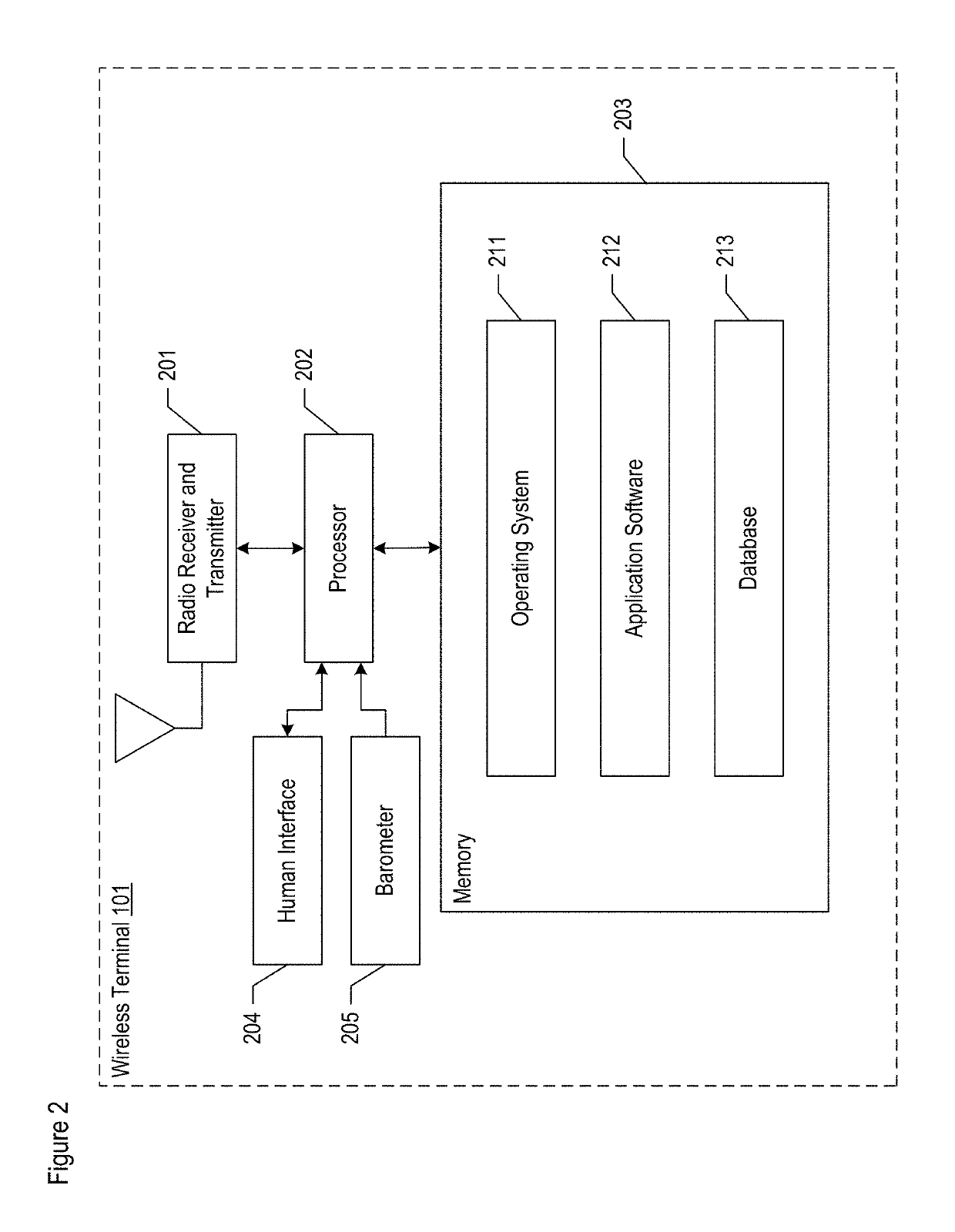

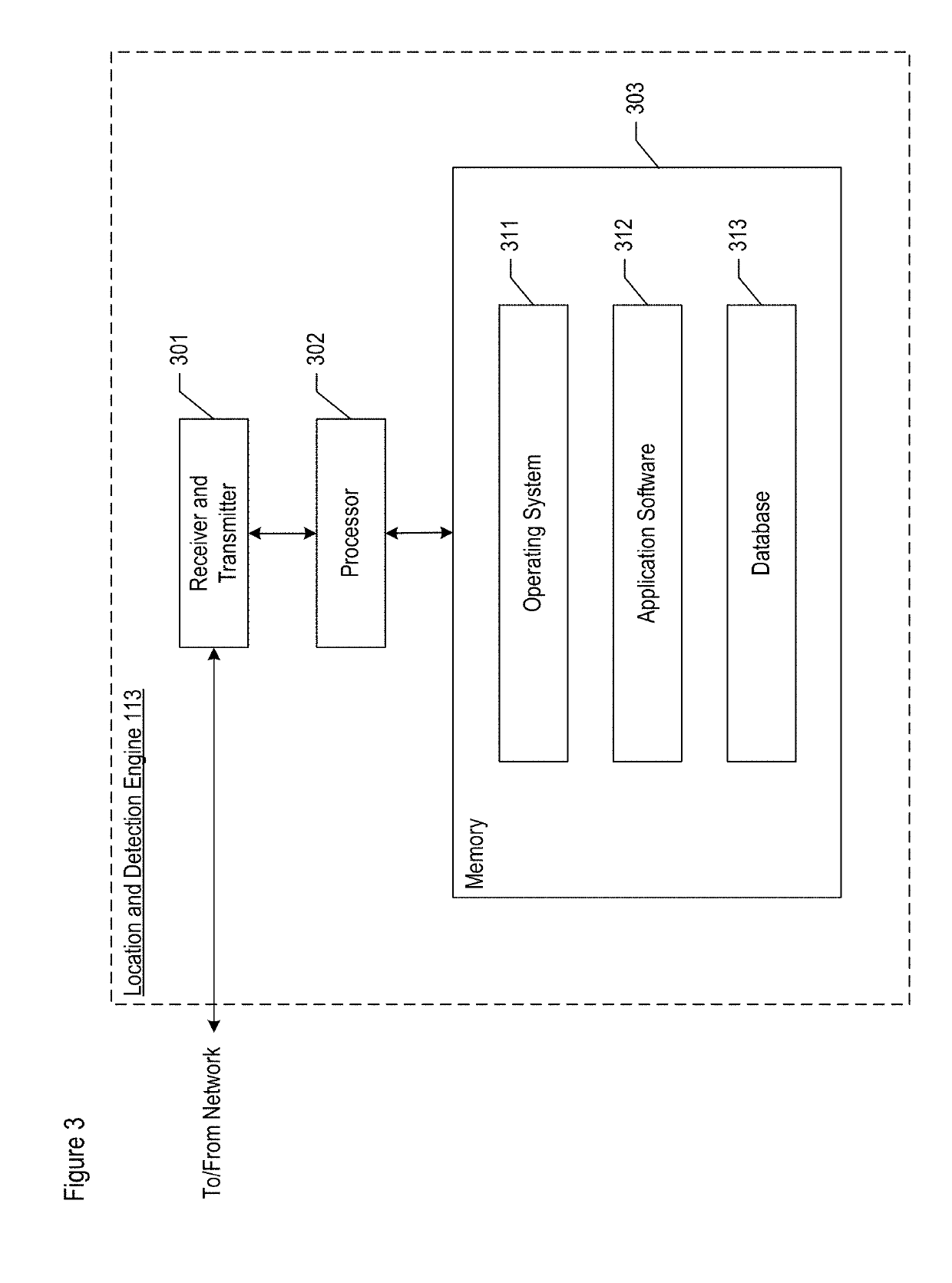

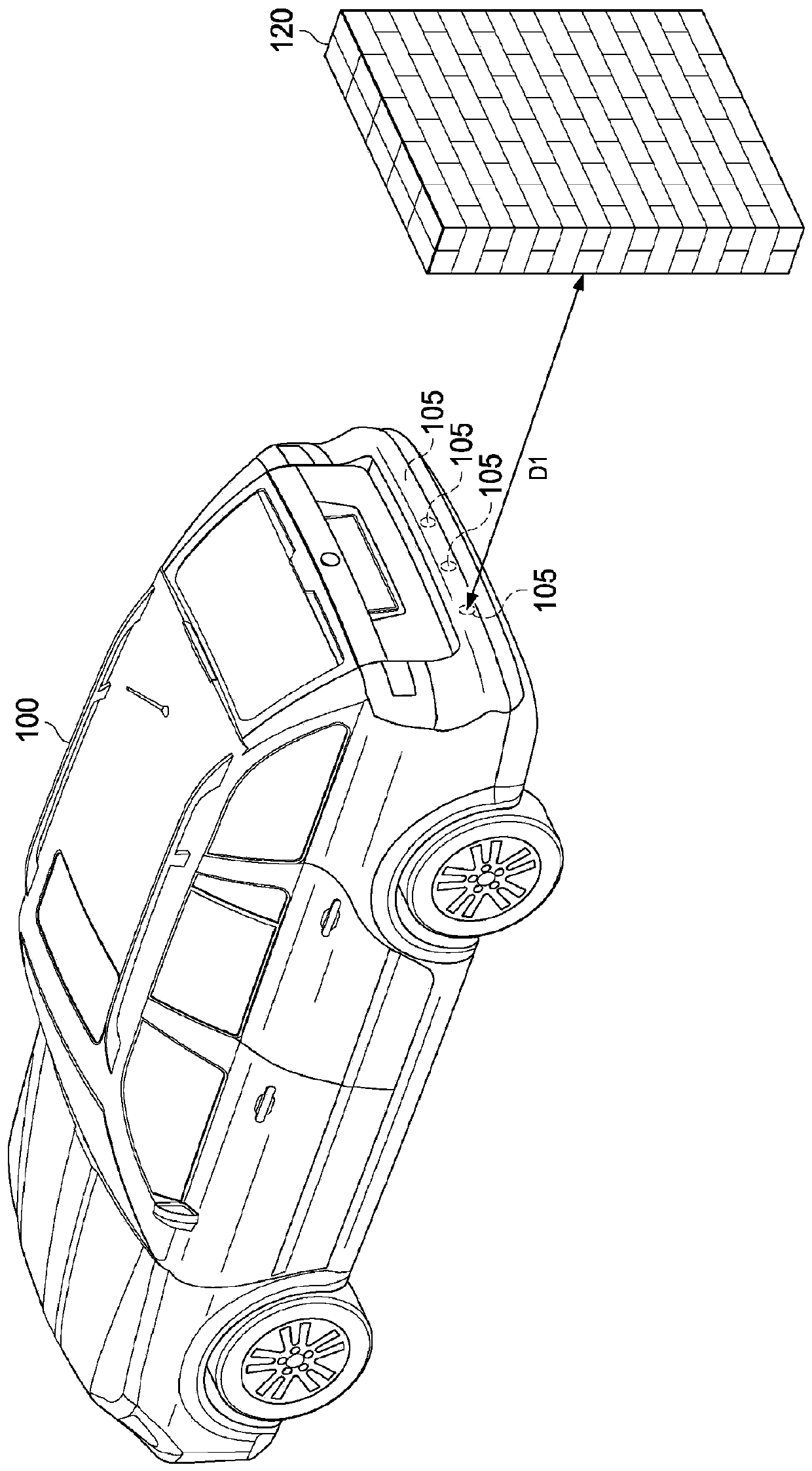

Estimation of the Location of a Wireless Terminal, Based on Characterizing a Pressure Wave

ActiveUS20190120665A1Converting sensor output using fluid meansParticular environment based servicesGeographic regionsEngineering

A technique for estimating the location of a wireless terminal at an unknown location in a geographic region. The technique is based on a two-part recognition, the first part being that a transient in atmospheric pressure attributed to a particular source, such as an entry door of a building opening and closing, is detectable in some environments while not being present in others. The second part of the recognition is that a correlation exists between i) the presence of a transient in the characterization of a pressure wave in the vicinity of a wireless terminal and ii) whether the wireless terminal is indoors or not. Transients in pressure waves are often present indoors but not outdoors. By accounting for the transients being detected or not being detected in the vicinity of the wireless terminal, the disclosed technique is able to estimate whether the wireless terminal is indoors.

Owner:POLARIS WIRELESS

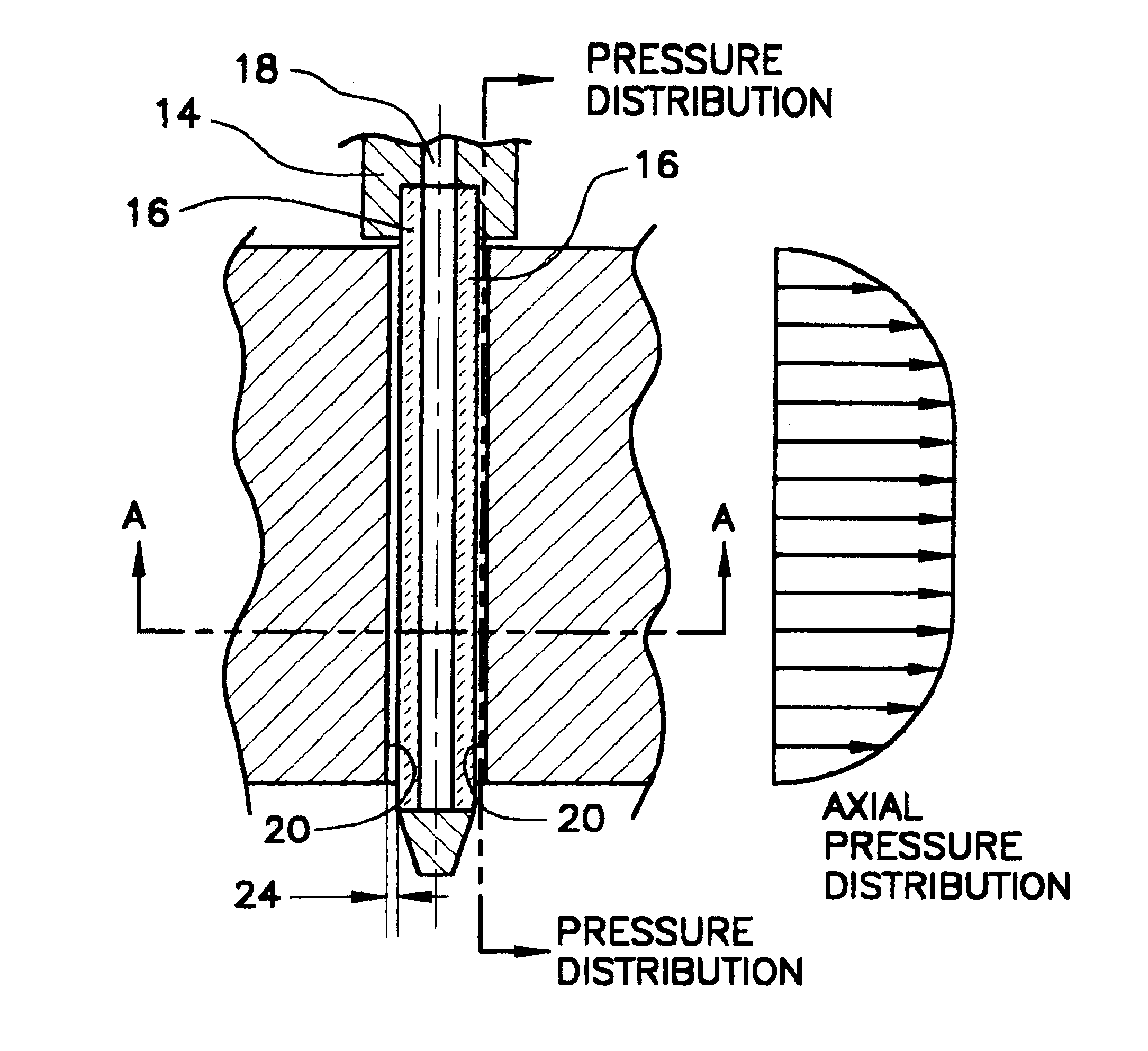

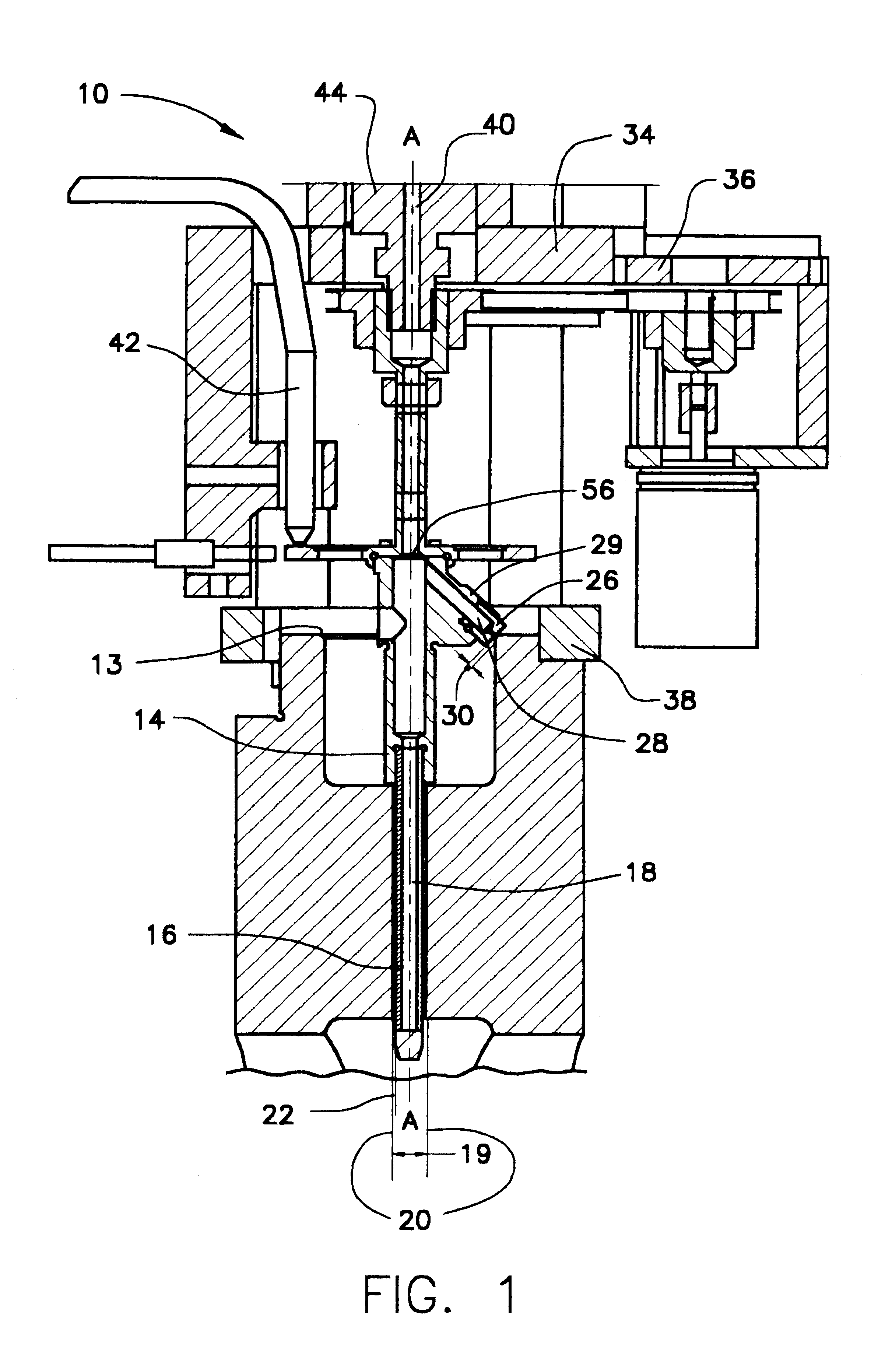

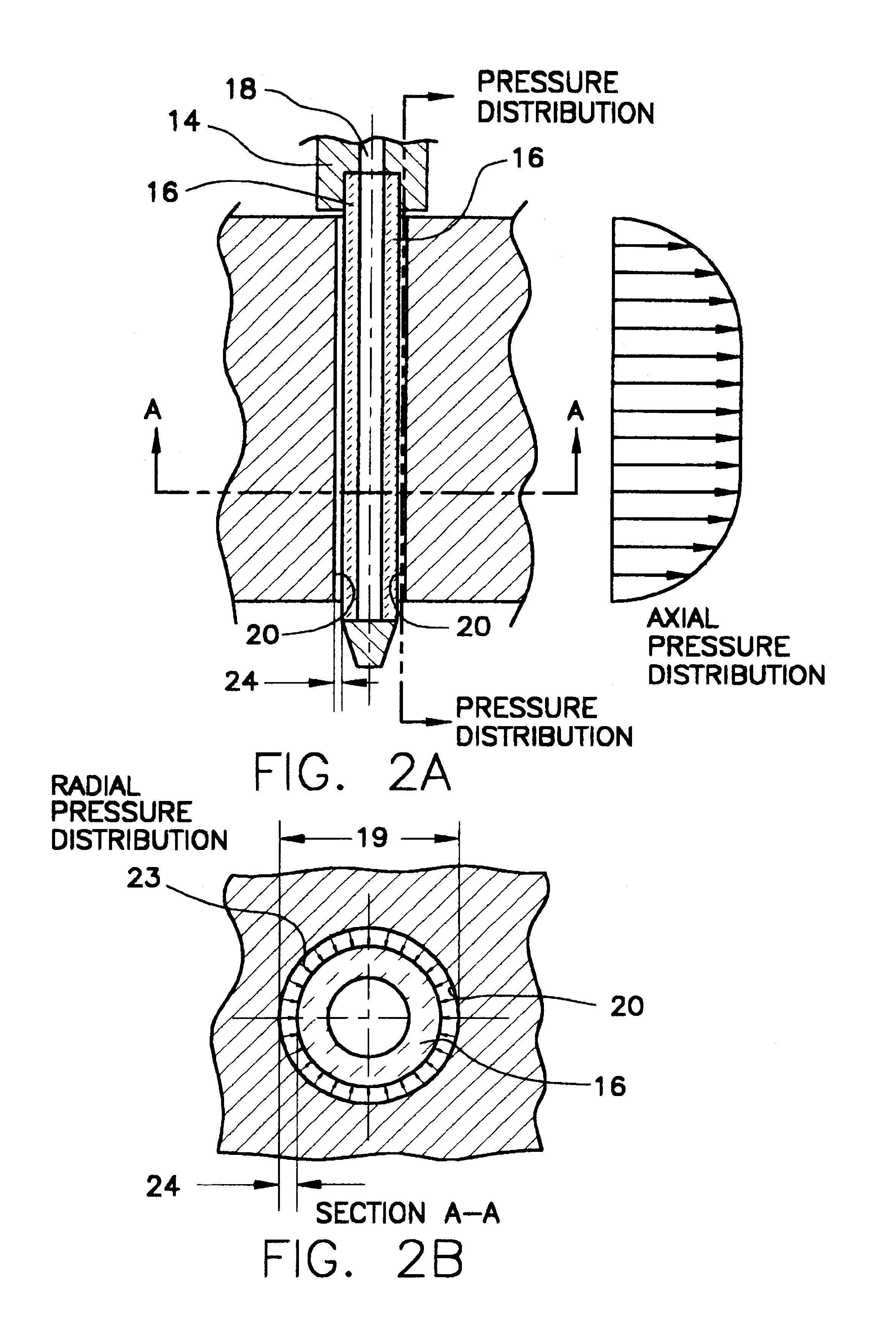

Fluid-aligned measurement apparatus and method

InactiveUS6843125B2Converting sensor output using fluid meansMachine gearing/transmission testingPhysicsFluid pressure

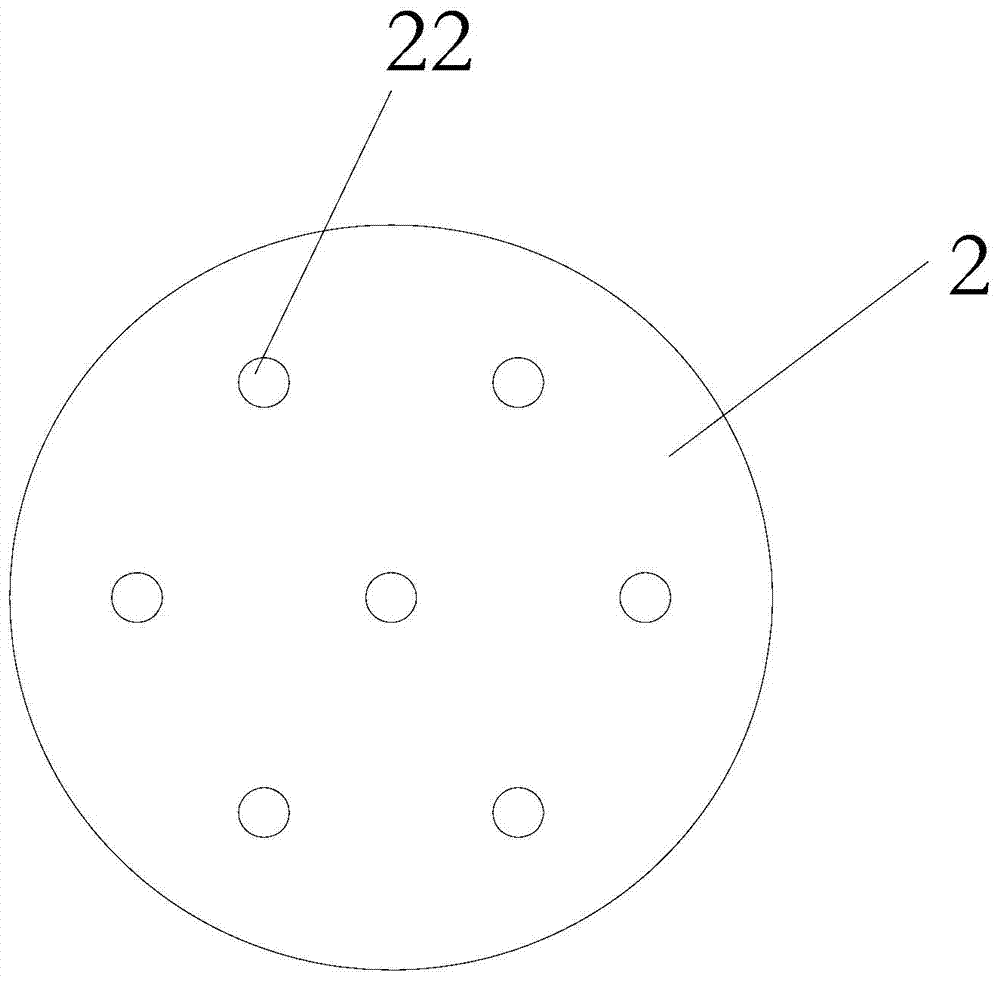

An apparatus 10 for producing one or more characterizing measurements of a surface 12 in relation to a repeatedly reproducible datum axis A-A, the apparatus 10 comprising a probe 14; a first porous surface 16 located on the probe 14, the first porous surface 16 being in communication with a first source of fluid pressure 18, the first porous surface 16 being located proximate to opposing walls 20 that defines a volume 22, so that a non-contacting fluid pressure gap 24 is formed between the first porous surface 16 and the walls 20, the first porous surface 16 defining the datum axis A-A; at least one second porous surface 26 located on the probe 14, the at least one second porous surface 26 being in communication with a second source of fluid pressure 28, the at least one second porous surface 26 being located in a cooperative relationship with the surface 12 to be measured, so that a non-contacting fluid pressure gap 30 is fanned between the at least one second porous surface 26 and the surface to be measured; and means for generating one or more characterizing measurements of the surface to be measured in relation to the datum axis.

Owner:PETERSON ROBERT +2

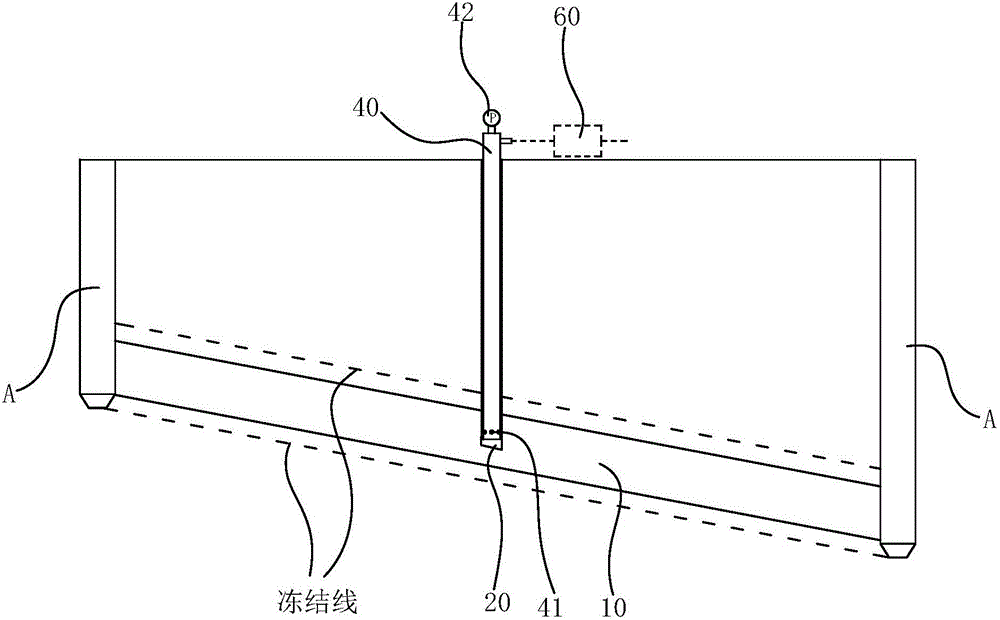

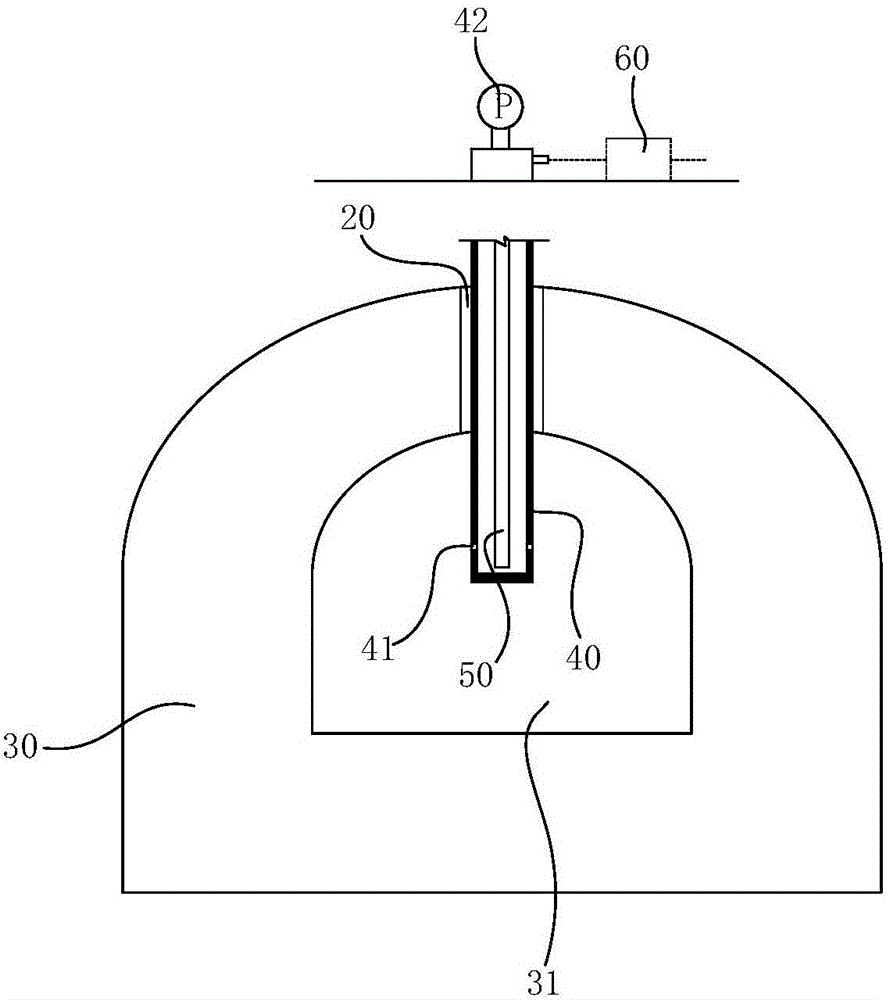

Hydrologic observation device capable of penetrating frozen wall

PendingCN106840228ADetermine excavation timeIntuitive response to frozen circlesConverting sensor output using fluid meansFluid pressure measurement using pressure-sensitive liquidHydrometryEngineering

The invention relates to a hydrologic observation device capable of penetrating a frozen wall. The hydrologic observation device comprises a plurality of hydrologic holes formed in the length direction of an inclined shaft or horizontal and inclined frozen construction passage; the hydrologic holes are formed in a way of being vertical to the ground and extend into the middle non-frozen region of the frozen wall; a pressure detection pipe is introduced into the hydrologic holes; water passing holes are formed in the pipe body, positioned in the non-frozen region of the middle of the frozen wall, of the pressure detection pipe; detection oil liquid is introduced into the pressure detection pipe; a pressure detection device used for detecting the inside pressure is arranged on the pressure detection pipe; during the inclined shaft frozen construction, the hydrologic holes are drilled; the pressure detection pipe is guided into the hydrologic holes; the detection oil liquid is pressed into the pressure detection pipe; the frozen closure condition of the frozen wall is obtained through observing the number change of the pressure detection device; the inclined well digging time is precisely determined.

Owner:CHINA COAL SPECIAL DRILLING ENG +1

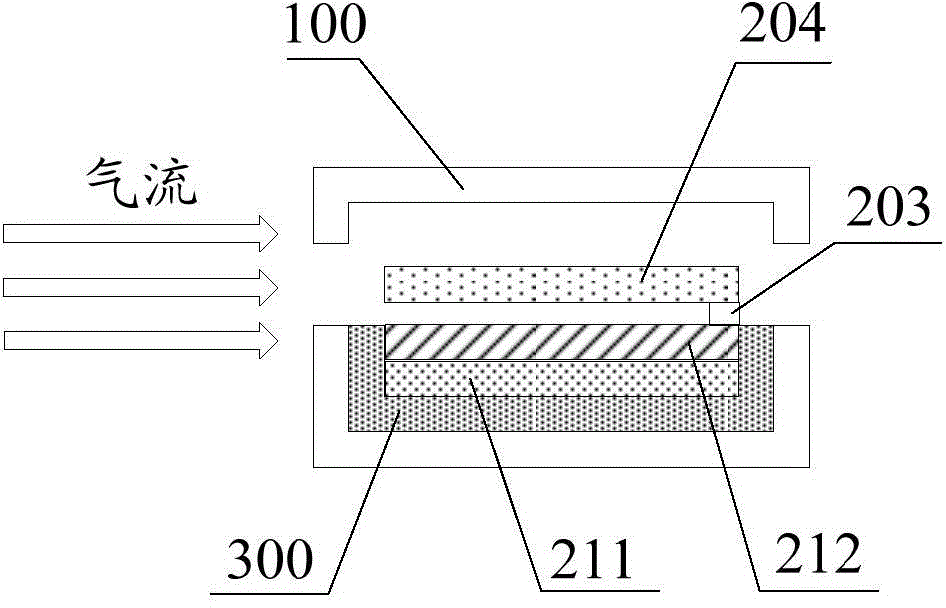

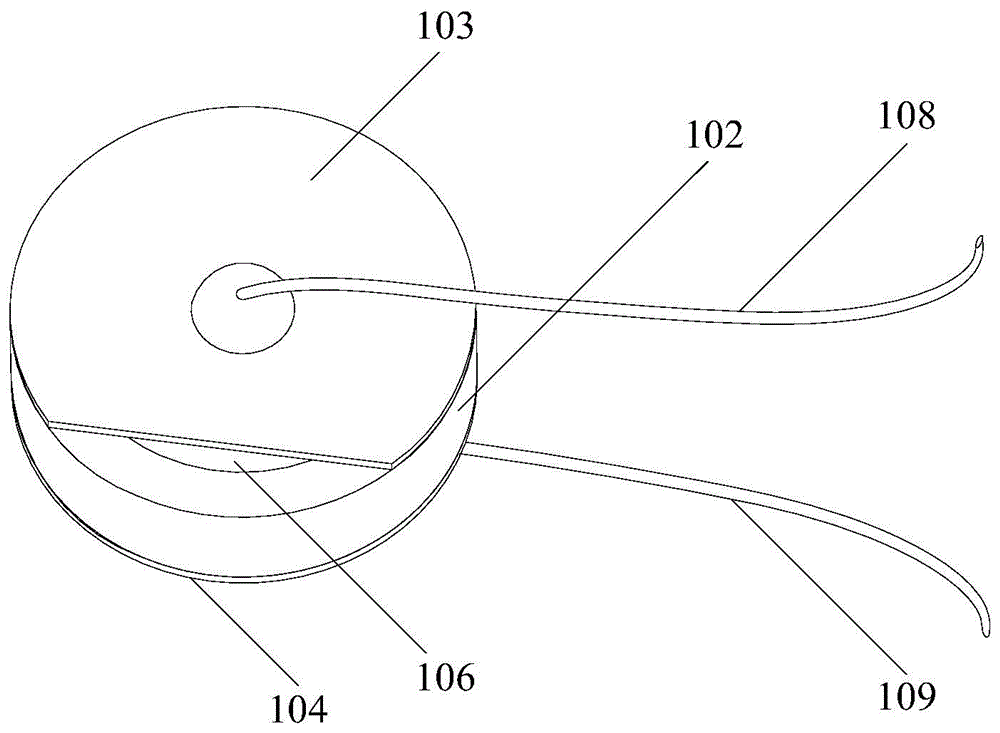

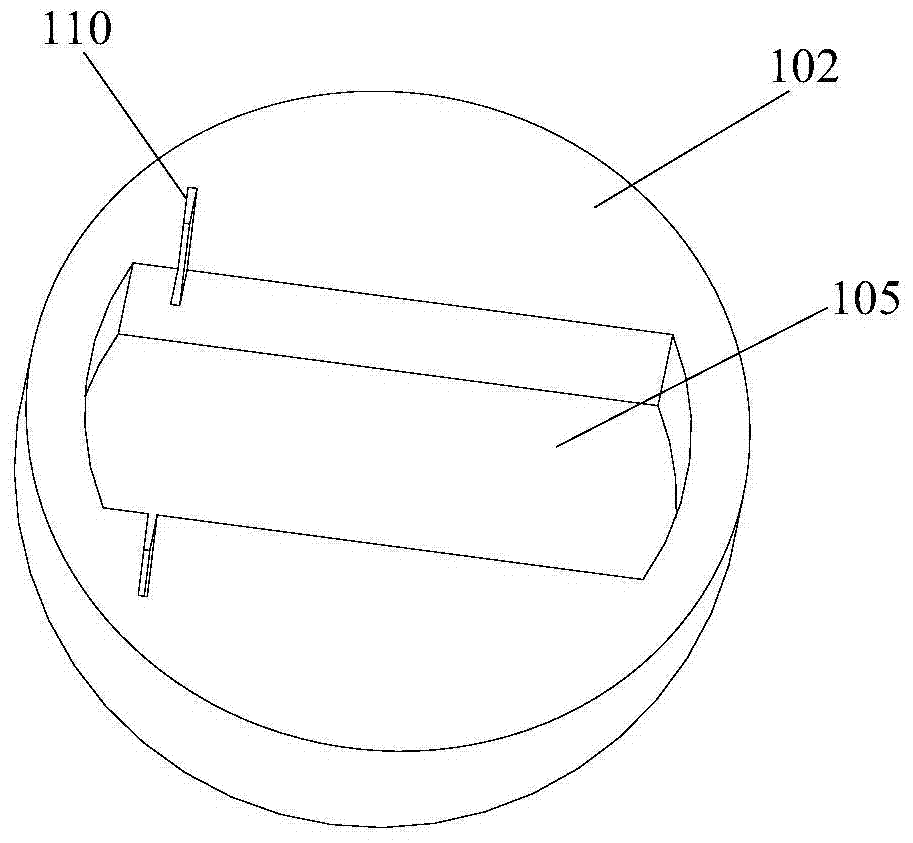

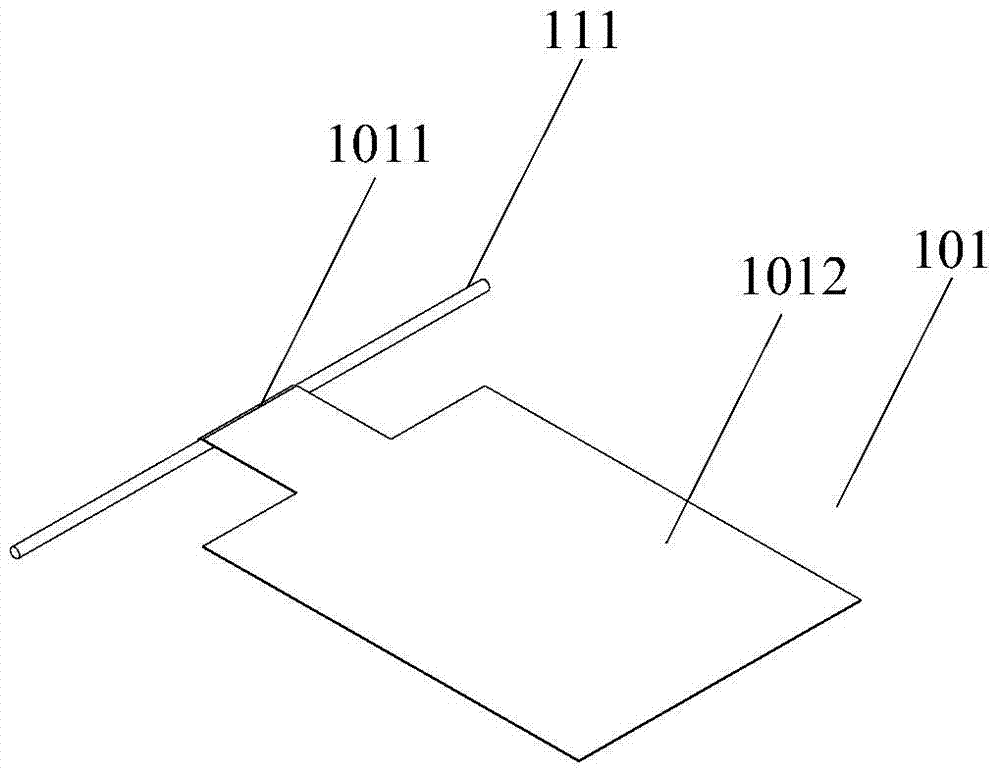

Pneumatic sensor

ActiveCN105203139ASimple manufacturing processIncrease the output voltageConverting sensor output using fluid meansEngineeringElectric signal

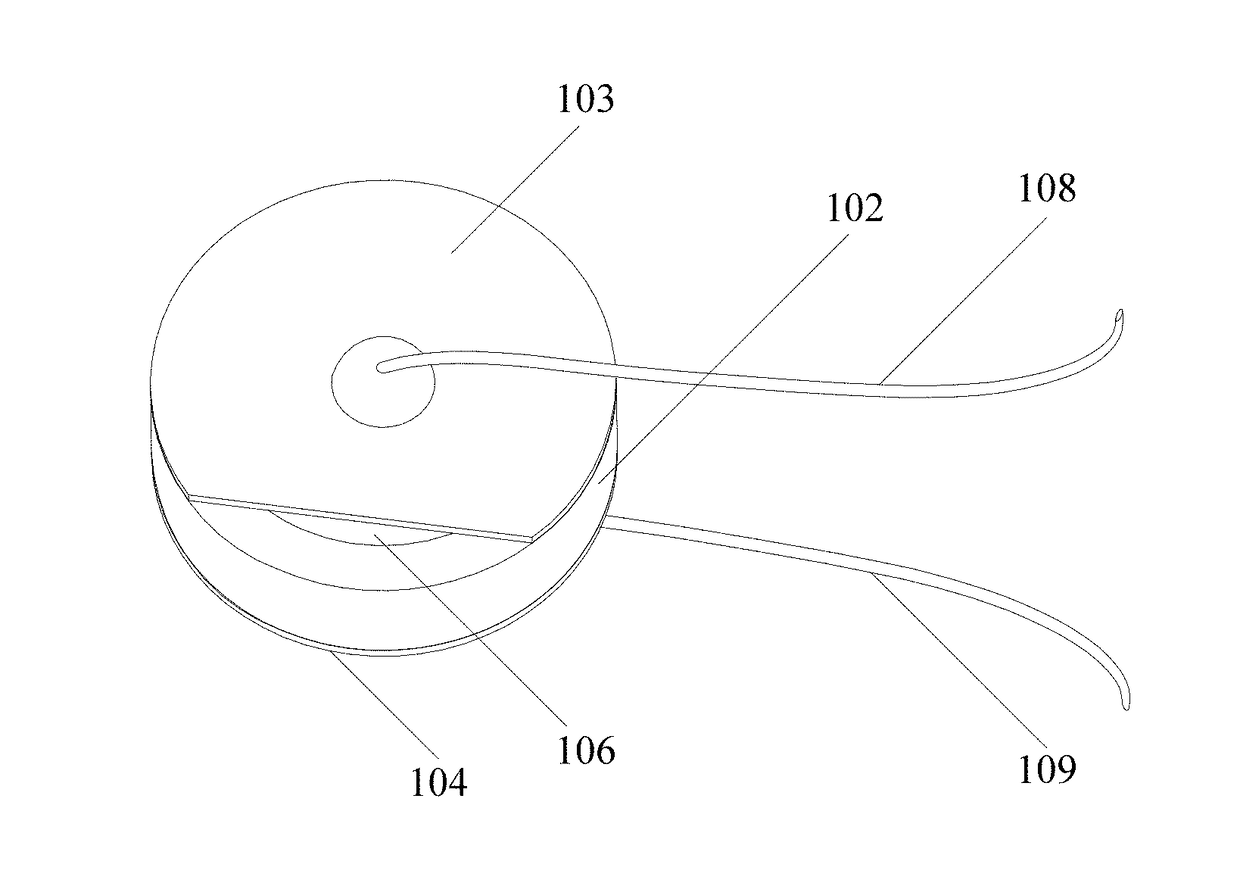

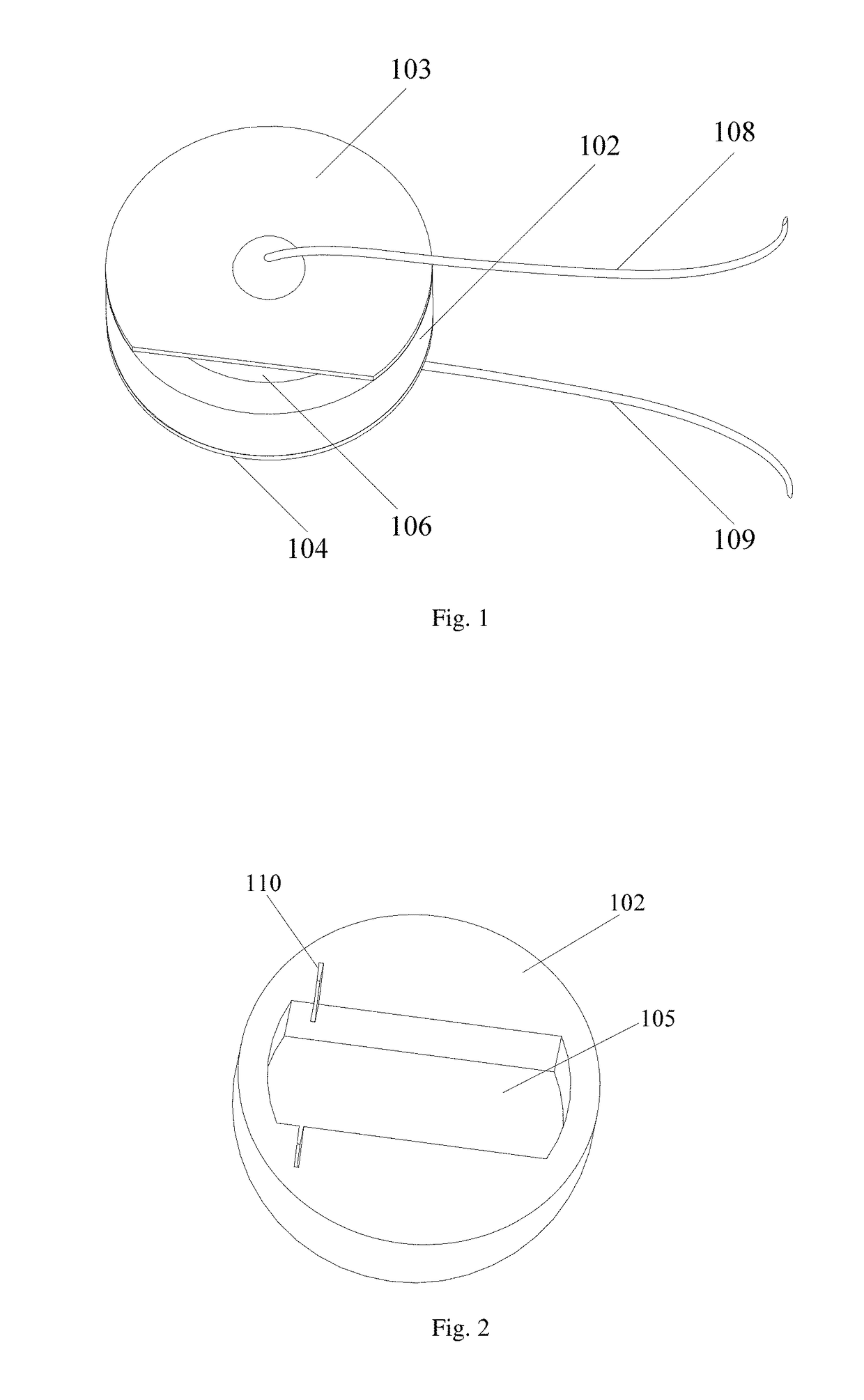

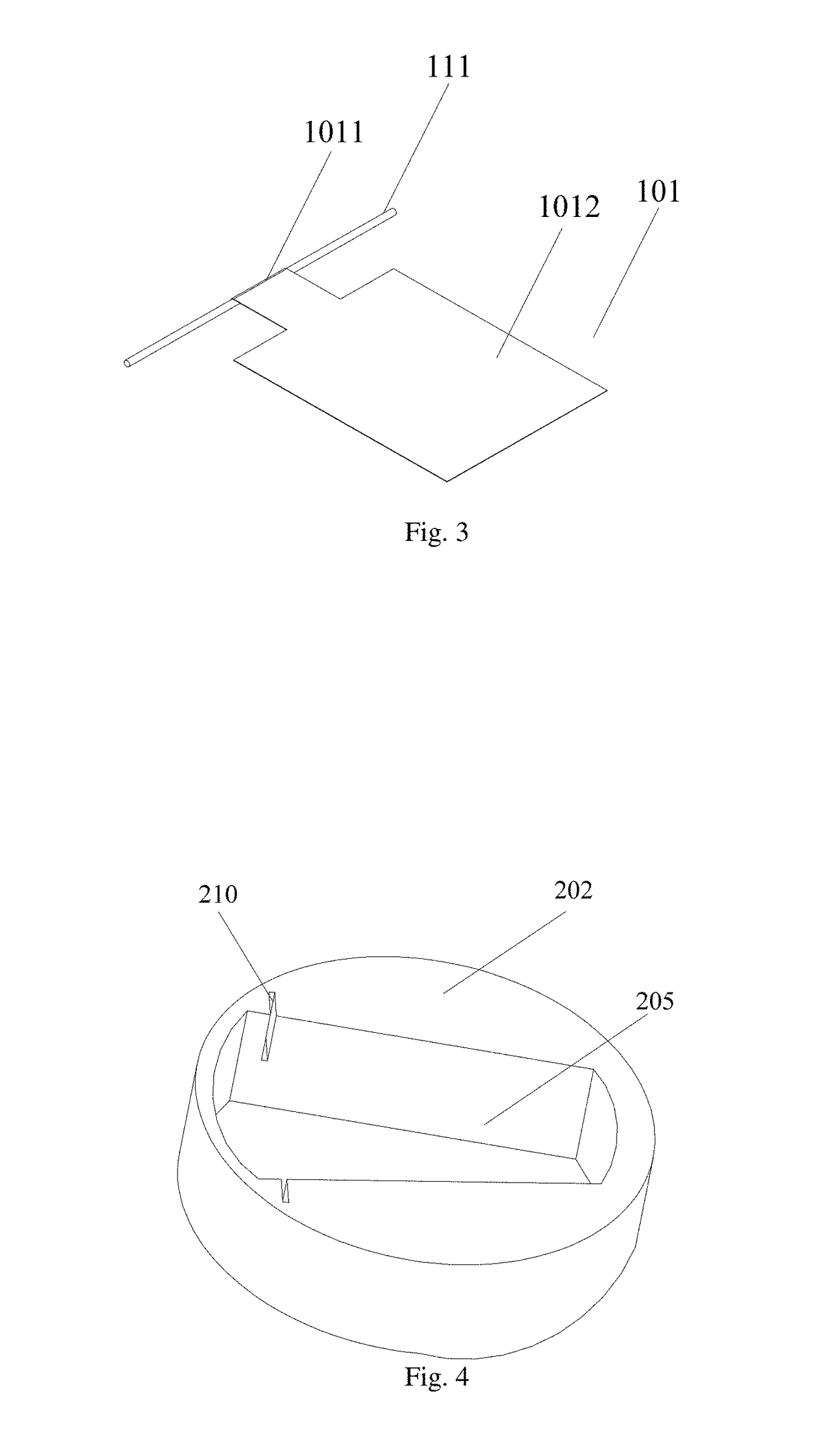

The invention discloses a pneumatic sensor which is provided with an air inlet and an air outlet. The pneumatic sensor comprises a first friction component, a shell, a second friction component and a third friction component, wherein the shell is provided with a hollow structure with a preset shape so as to form an air flow channel, and the air flow channel is communicated with the air inlet and the air outlet, thereby enabling an air flow to get into the air flow channel through the air inlet and then flow out through the air outlet; and the first friction component is arranged in the air flow channel, and the second friction component and the third friction component are arranged at positions where the second friction component and the third friction component can be contacted with the first friction component. When the air flow gets into the air flow channel through the air inlet, the first friction component generates friction with the second and / or the third friction component because of an effect of the air flow, and electric signals are generated. The second friction component and the third friction component comprise an electric signal output end of the pneumatic sensor. The pneumatic sensor disclosed by the invention can simplify the manufacturing process of existing pneumatic sensors, a driving force imposed on the first friction component in the pneumatic sensor by the air flow is improved, and thus the sensitivity and the stability of the pneumatic sensor in operation are improved.

Owner:NAZHIYUAN TECH TANGSHAN LLC

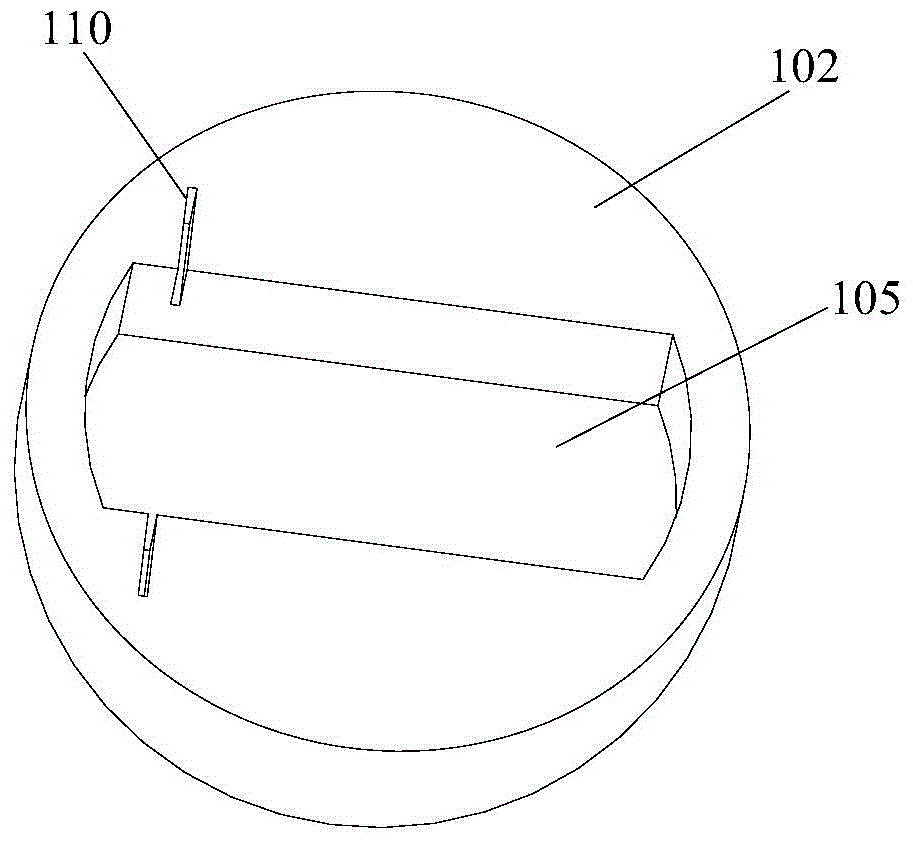

Pneumatic sensor of electronic cigarette, air flow processing device and electronic cigarette

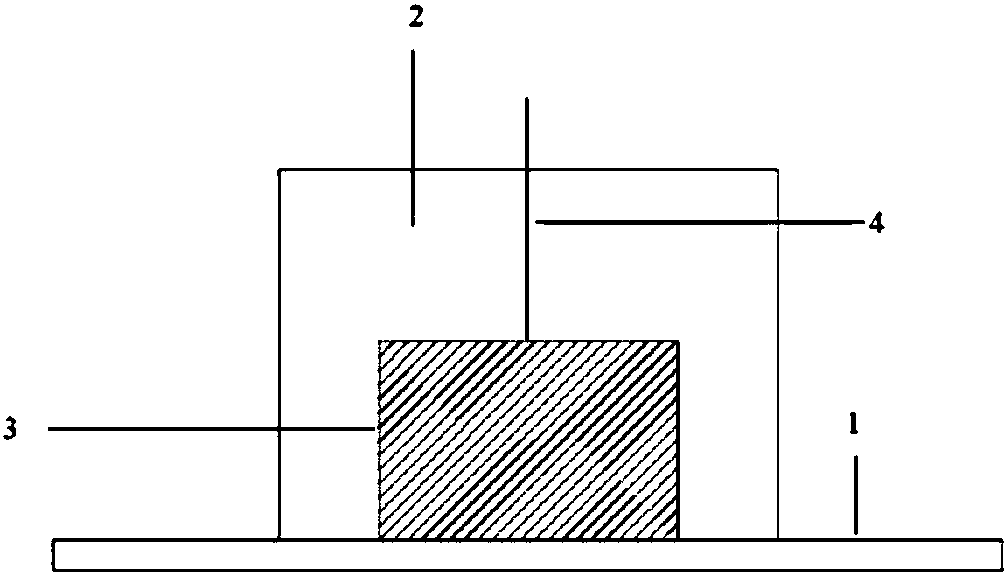

ActiveCN105433439AReduce manufacturing costImprove stabilityConverting sensor output using fluid meansTobacco devicesManufacturing technologySignal processing circuits

The invention provides a pneumatic sensor of an electronic cigarette, an air flow processing device and the electronic cigarette. The pneumatic sensor of the electronic cigarette comprises an electrode plate, a vibrating diaphragm unit and a shell. The air flow processing device comprises the pneumatic sensor of the electronic cigarette and a circuit module. The pneumatic sensor of the electronic cigarette is used for sensing flowing of air flow and outputting a sensing signal. The circuit module receives and processes the sensing signal and outputs a control signal. The electronic cigarette comprises the air flow processing device, a cigarette rod, an atomizer and a power device. The pneumatic sensor of the electronic cigarette, the air flow processing device and the electronic cigarette solve the problems that a pneumatic sensor in the prior art is high in manufacturing cost, complex in manufacturing technology, high in requirement for an external signal processing circuit and prone to external vibration interference.

Owner:NAZHIYUAN TECH TANGSHAN LLC

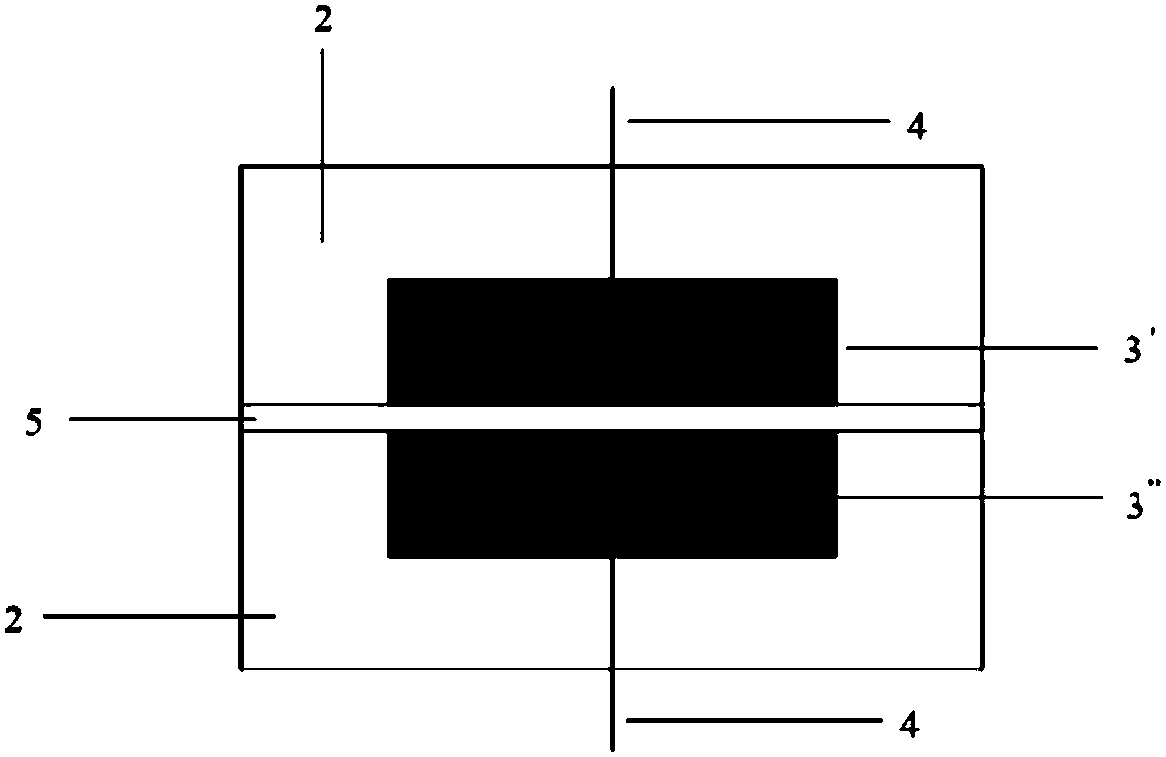

Contact pressure and position detecting device and detecting method for same

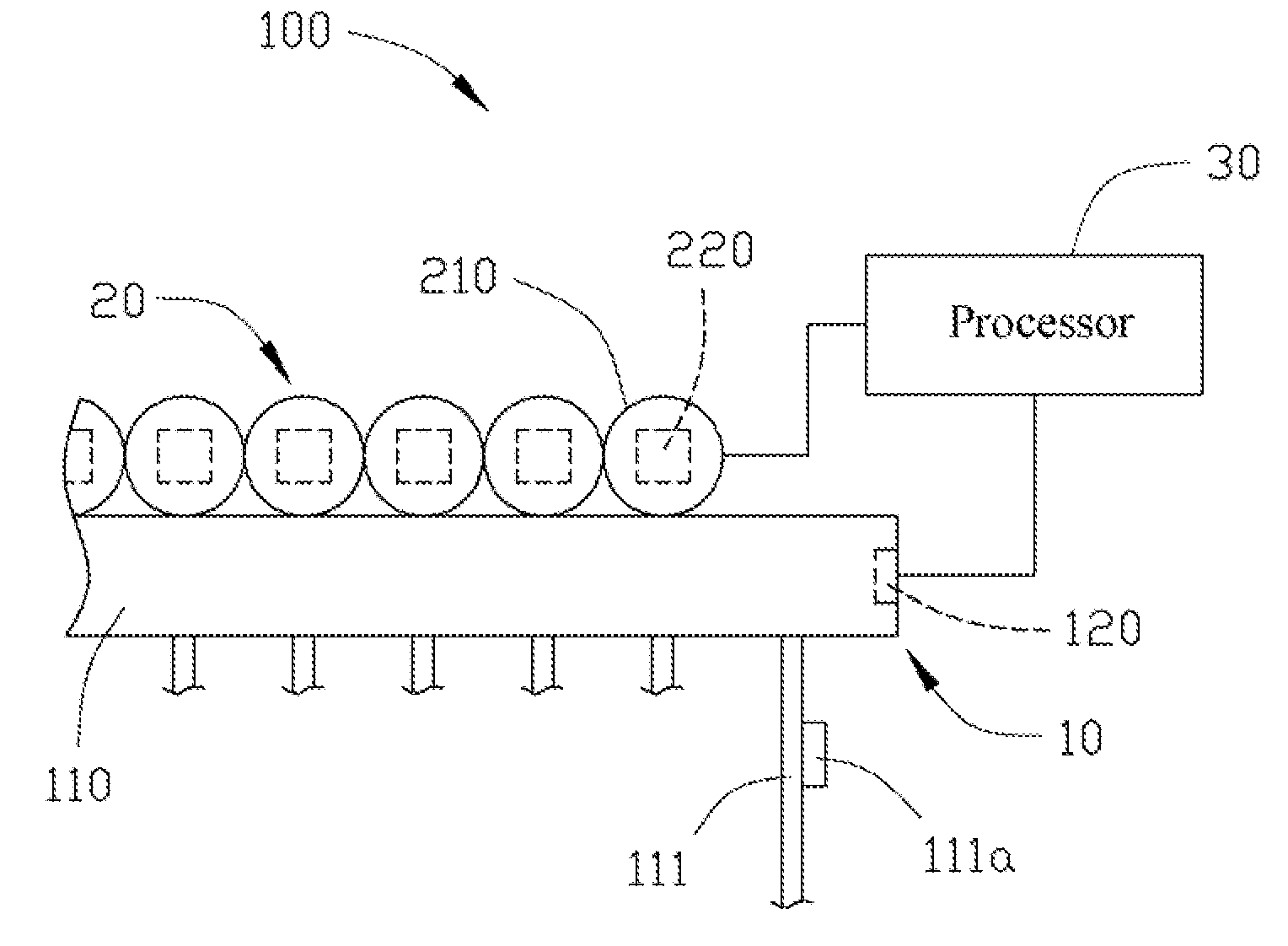

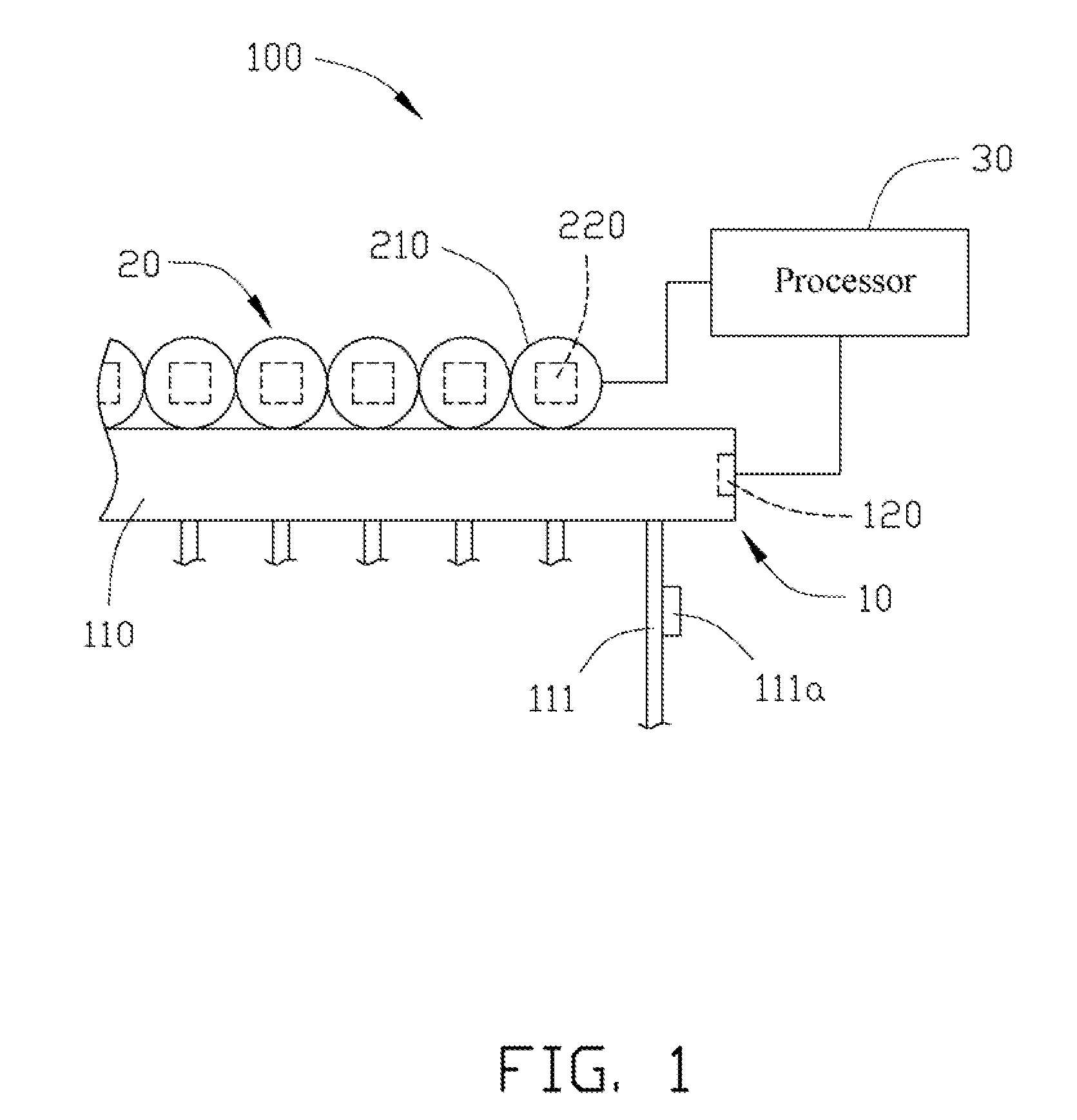

InactiveUS20110010114A1Converting sensor output using fluid meansFlow propertiesLocation detectionElectricity

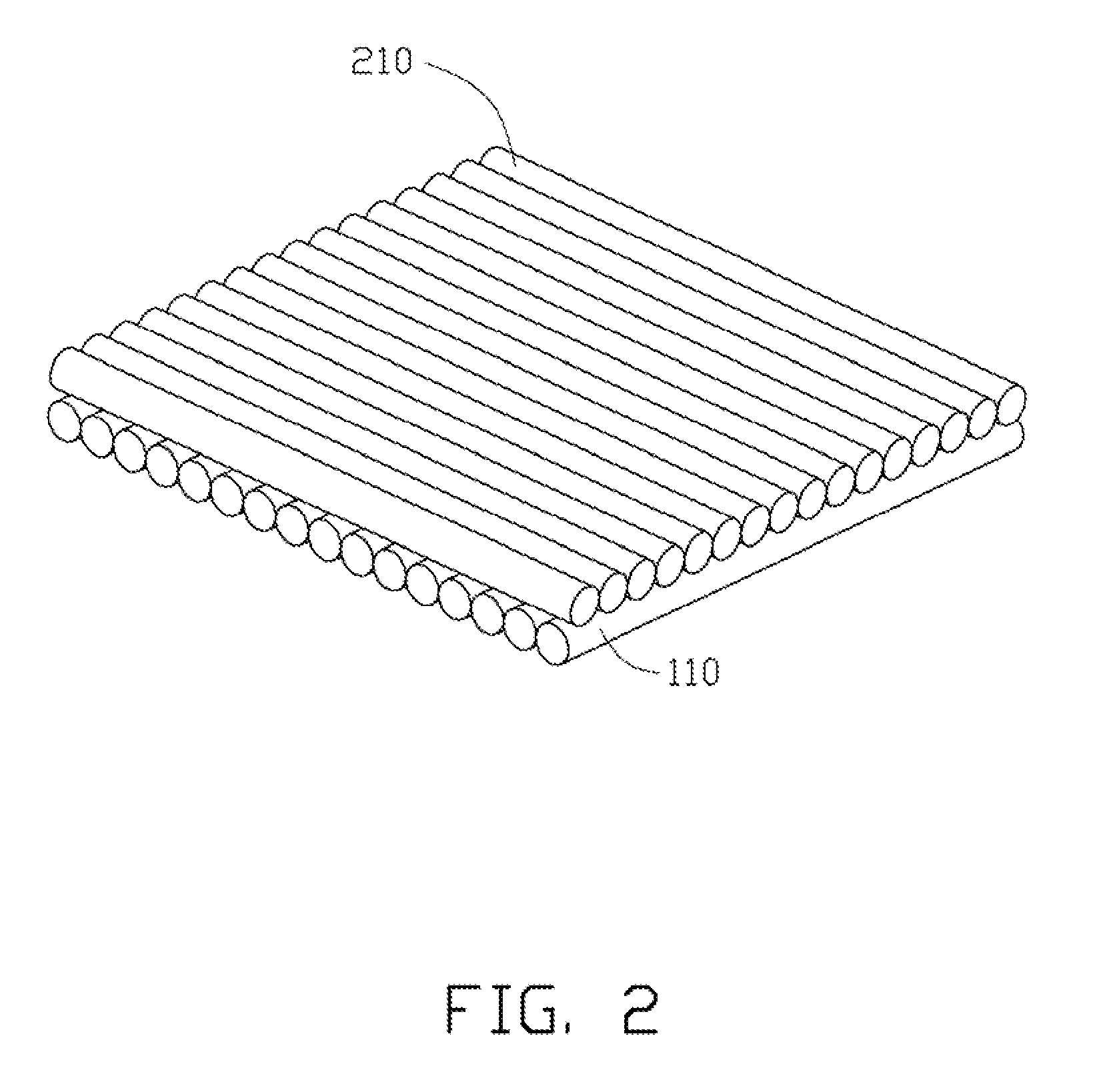

A contact pressure and position detecting device includes a first sensing layer, a second sensing layer located on the first sensing layer, and a processor. The first sensing layer includes a number of parallel first pipes, and the second sensing layer includes a number of parallel second pipes perpendicular to the first pipes. Each first pipe includes a first pressure sensor received therein for generating a first electrical signal according to the gas pressure therein. Each second pipe includes a second pressure sensor received therein for generating a second electrical signal according to the gas pressure therein. The processor compares the first electrical signals with a first threshold value, and the second electrical signals with a second threshold value to judge which first pipe and second pipe is pressed, and then obtains the contact position on the detecting device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Injection quality detection method of L-shaped water pipe used for ice production water storage box of refrigerator and detection device

ActiveCN110530587AThe test result is accurateAvoid measurement errorsMachine part testingMeasurement of fluid loss/gain rateWater storageEngineering

The invention relates to an injection quality detection method of an L-shaped water pipe used for an ice production water storage box of a refrigerator and a detection device. The detection method includes the following steps: recording air pressure A of an air source at the time when the same is not communicated onto the to-be-detected water pipe; communicating the air source to one end of the to-be-detected water pipe, and recording air pressure B of the air source; comparing a first difference value of the air pressure B and the air pressure A and a standard difference value range, determining a product as qualified if the same is in the range, and determining the product as unqualified if the same is out of the range; closing the other end of the to-be-detected water pipe, recording air pressure C in the to-be-detected water pipe, comparing a second difference value of the pressure C and a standard value and a first standard difference value, and determining the product as unqualified if the second difference value is greater than the first standard difference value; and if the second difference value is less than the first standard difference value, stopping air intaking, recording air pressure D, comparing a third difference value of the air pressure D and the air pressure C and the second standard difference value, determining the product as qualified if the third difference value is less than the second standard difference value, and determining the product as unqualified if the third difference value is greater than the second standard difference value. Through themethod, a detection result on injection quality of the water pipe is accurate, and detection speed is high.

Owner:苏州向心圆电子科技有限公司

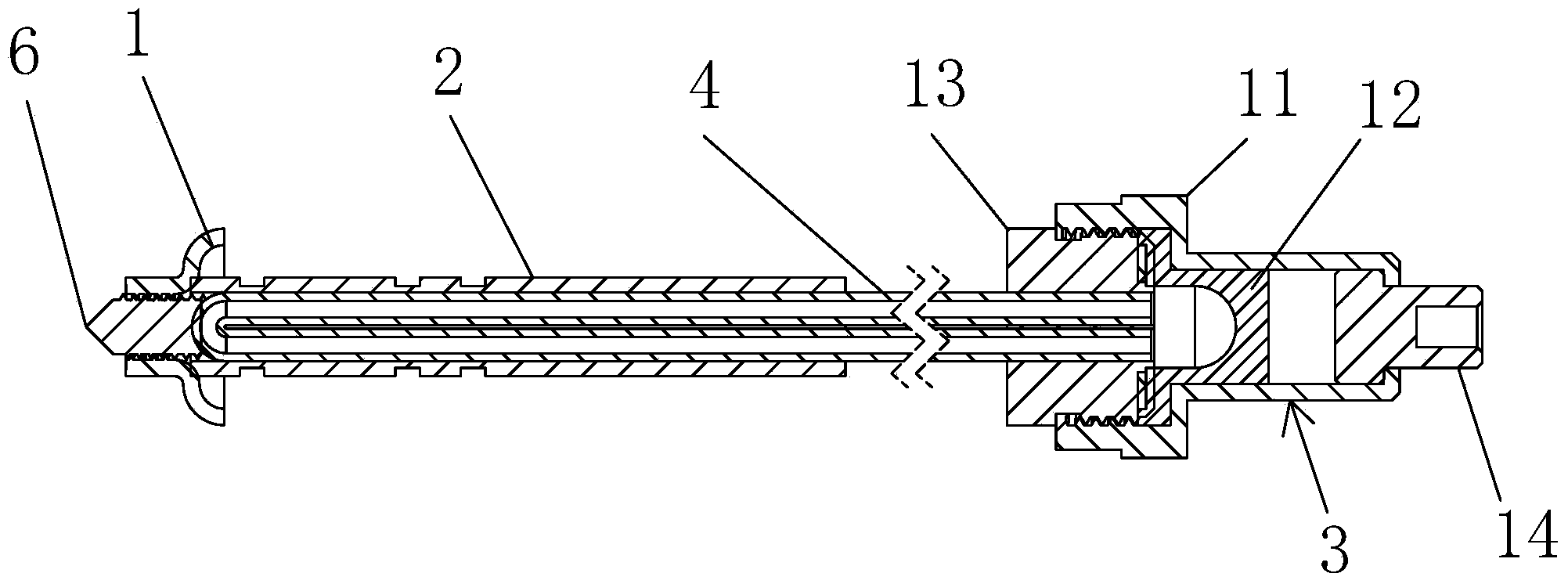

Heat sensor with driving function

InactiveCN104019838AAvoid hidden dangersEliminate the disadvantages of high temperature resistanceConverting sensor output using fluid meansEngineeringControl switch

Provided is a heat sensor with a driving function. The heat sensor is provided with a sleeve, an air cylinder for driving and a U-shaped tube. One end of the sleeve is provided with a sleeve cap, and the other end of the sleeve is open; one end of the U-shaped tube is inserted into the sleeve from the open end of the sleeve, and the other end of the U-shaped tube is connected with the air cylinder; sleeve inner threads running through the sleeve are formed in the center of the sleeve cap, and the sleeve cap is connected with a heat collection needle through the sleeve inner threads, wherein the heat collection needle is used for absorbing heat sources. The air cylinder is provided with a two-hole screw arranged at one end of a longitudinally through air cylinder body and used for being inserted into the two open ends of the U-shaped tube, a rubber sealing cap arranged in the air cylinder body and combined with the two-hole screw tightly and a T-shaped tubular piston arranged at the other end of the air cylinder body, and the T-shaped tubular piston can stretch out to be used for driving an external part to move when the rubber sealing cap is heated to expand. Thermal cycle power can be generated after the inner portion of the heat sensor is under the high temperature, power is conveyed to a control switch repeatedly and continuously, and the heat sensor cannot be damaged because of flame ablation, and is reliable and durable.

Owner:李仲伦

System and method for detecting ground engaging tool float for an agricultural implement

In one aspect, a system for detecting ground engaging tool float for an agricultural implement may include an implement having a ground engaging tool pivotally coupled to a frame and a biasing element coupled between the frame and the ground engaging tool. The biasing element may be configured to bias the ground engaging tool to a predetermined ground engaging tool position relative to the frame. The system may also include a sensor configured to detect a parameter indicative of a current position of the ground engaging tool relative to the frame. Additionally, the system may include a controller configured to monitor the current position of the ground engaging tool based on measurement signals received from the sensor and identify a time period across which the ground engaging tool is displaced from the predetermined ground engaging tool position. The controller may be further configured to compare the identified time period to a threshold time period to determine when a ground engaging tool float event is occurring during operation of the implement.

Owner:INC BLUE LEAF I

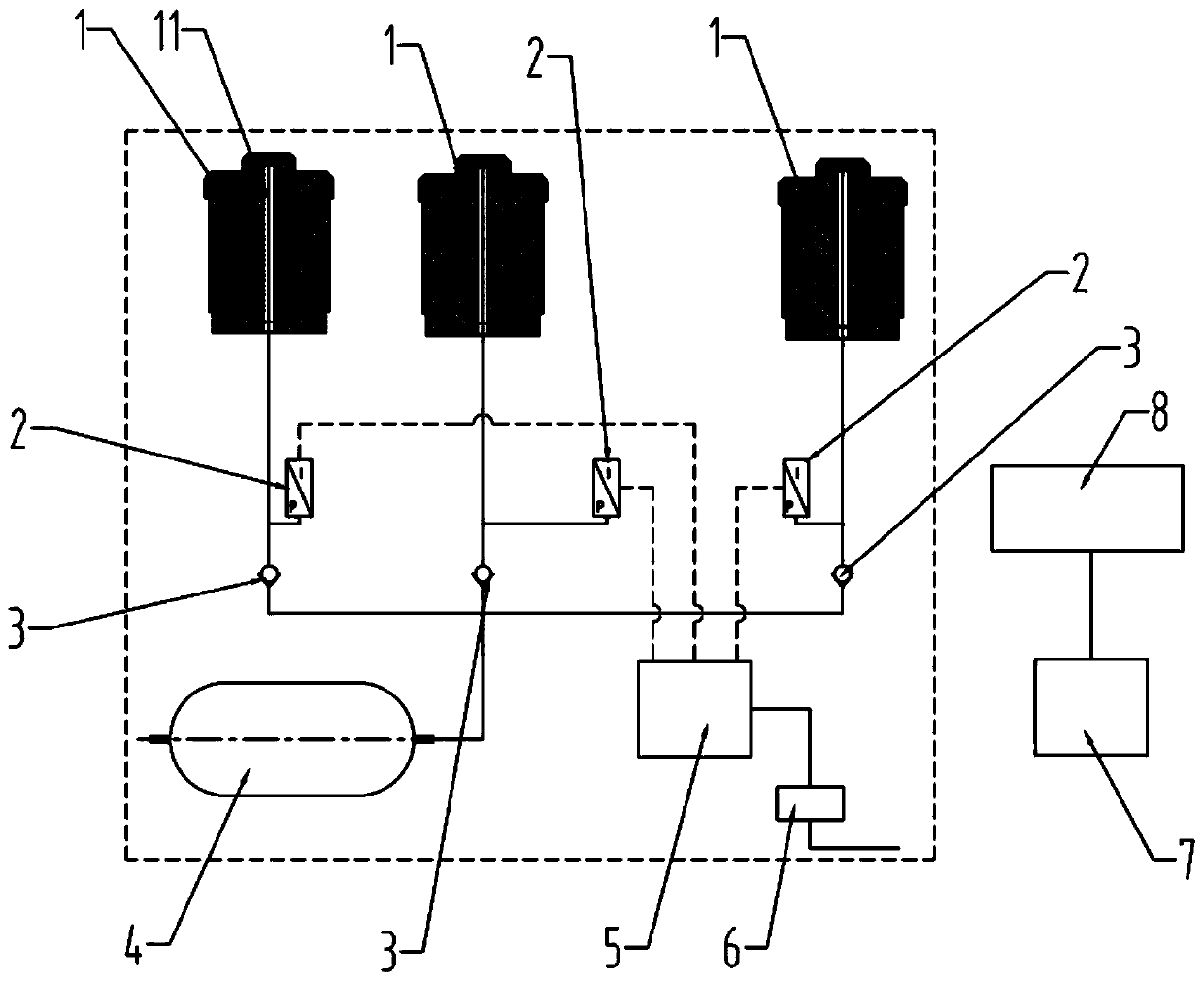

Cutter head wear detection device for shield machine

PendingCN110645924AEnsure safetyGuarantee stabilityConverting sensor output using fluid meansUsing fluid meansGas cylinderStructural engineering

The present invention discloses a cutter head wear detection device for a shield machine. The cutter head wear detection device comprises a detection head, a pressure sensor, a check valve, a gas cylinder, a signal transmitter, a conductive slip ring and a signal receiver; the detection head is internally provided with a detection hole; the detection hole is connected with the gas cylinder through a pipeline; the connection pipeline between the detection head and the gas cylinder is provided with the check valve and the pressure sensor; and the pressure sensor is configured to check the pressure on the connection pipeline and transmit the pressure to a controller of the shield machine through the signal transmitter and the signal receiver. According to the cutter head wear detection device for the shield machine provided by the present invention, the pressure signal can be automatically detected when the detection hole is worn, the pressure signal can be wirelessly transmitted to thecontroller, and a shield machine operation program is locked, so that the machine is unable to continue digging, and the safety and stability of the cutter head structure of the shield machine are ensured; the compressed air is used for detection, and the compressed air will not pollute the water and soil in the tunnel after the detection hole is worn through; and the cutter head wear detection device for the shield machine has no hydraulic rotary joint, and has a compact installation structure for convenient installation, so that the space and the cost are saved.

Owner:XCMG KAIGONG HEAVY IND NANJING

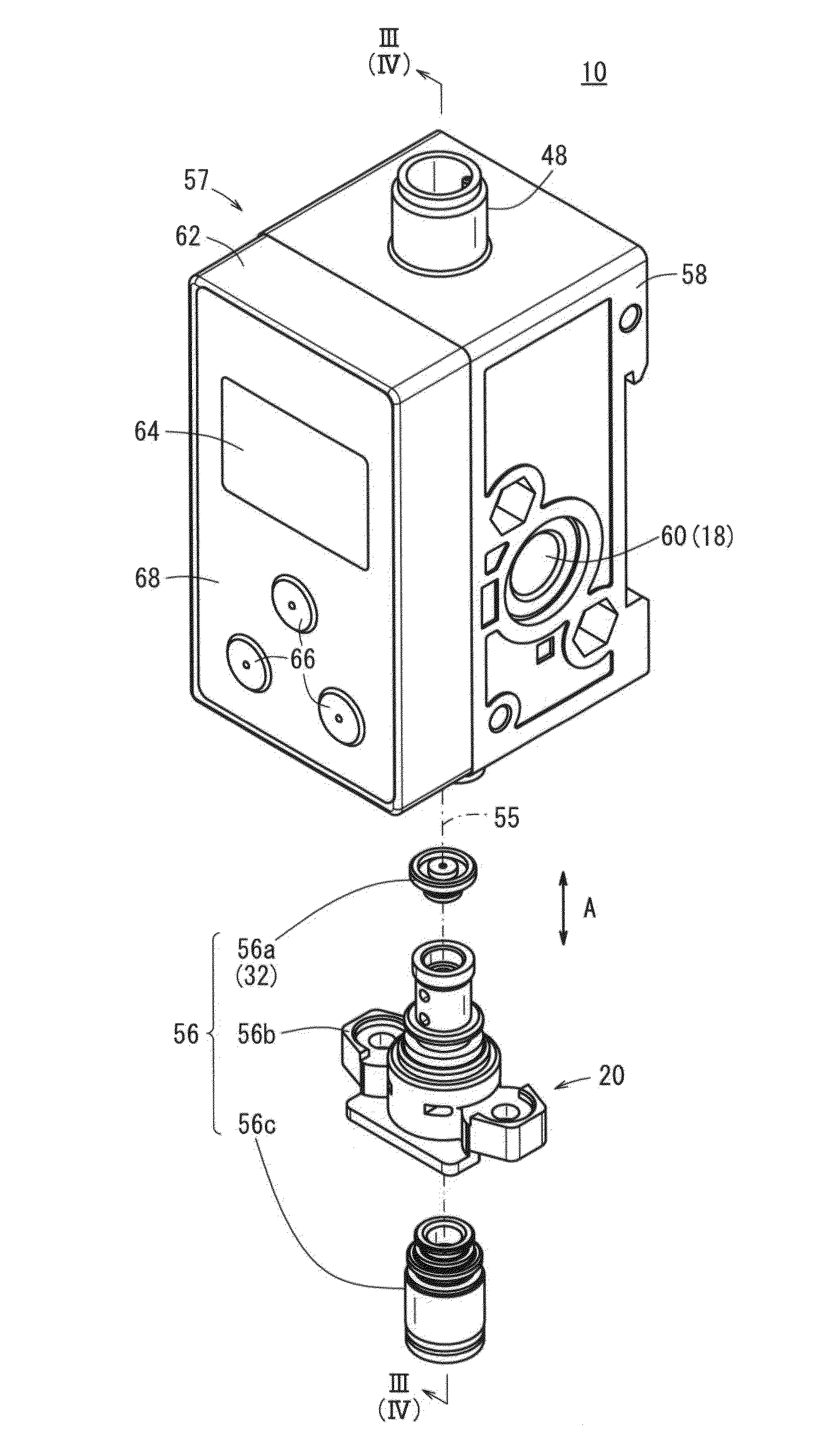

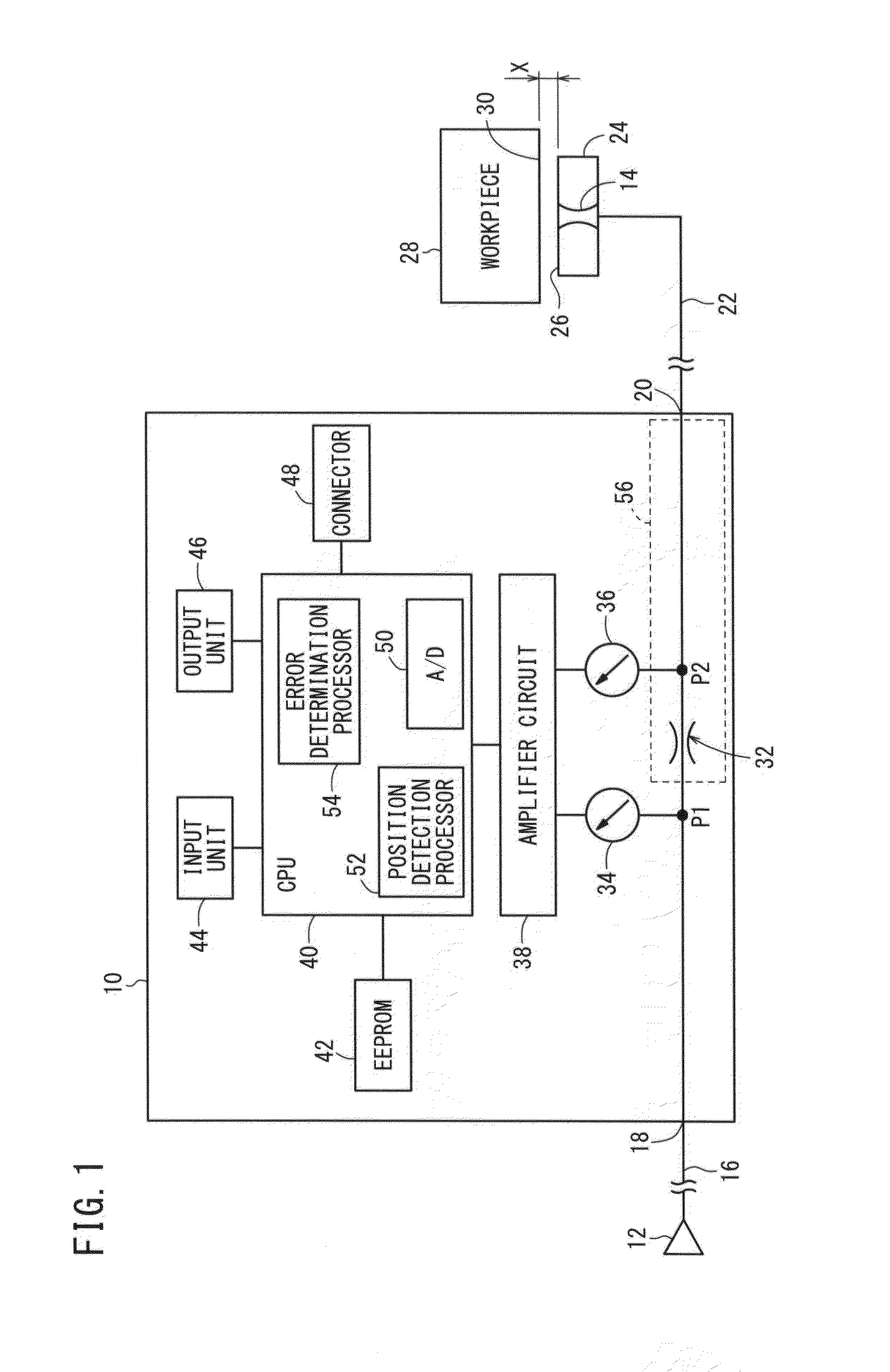

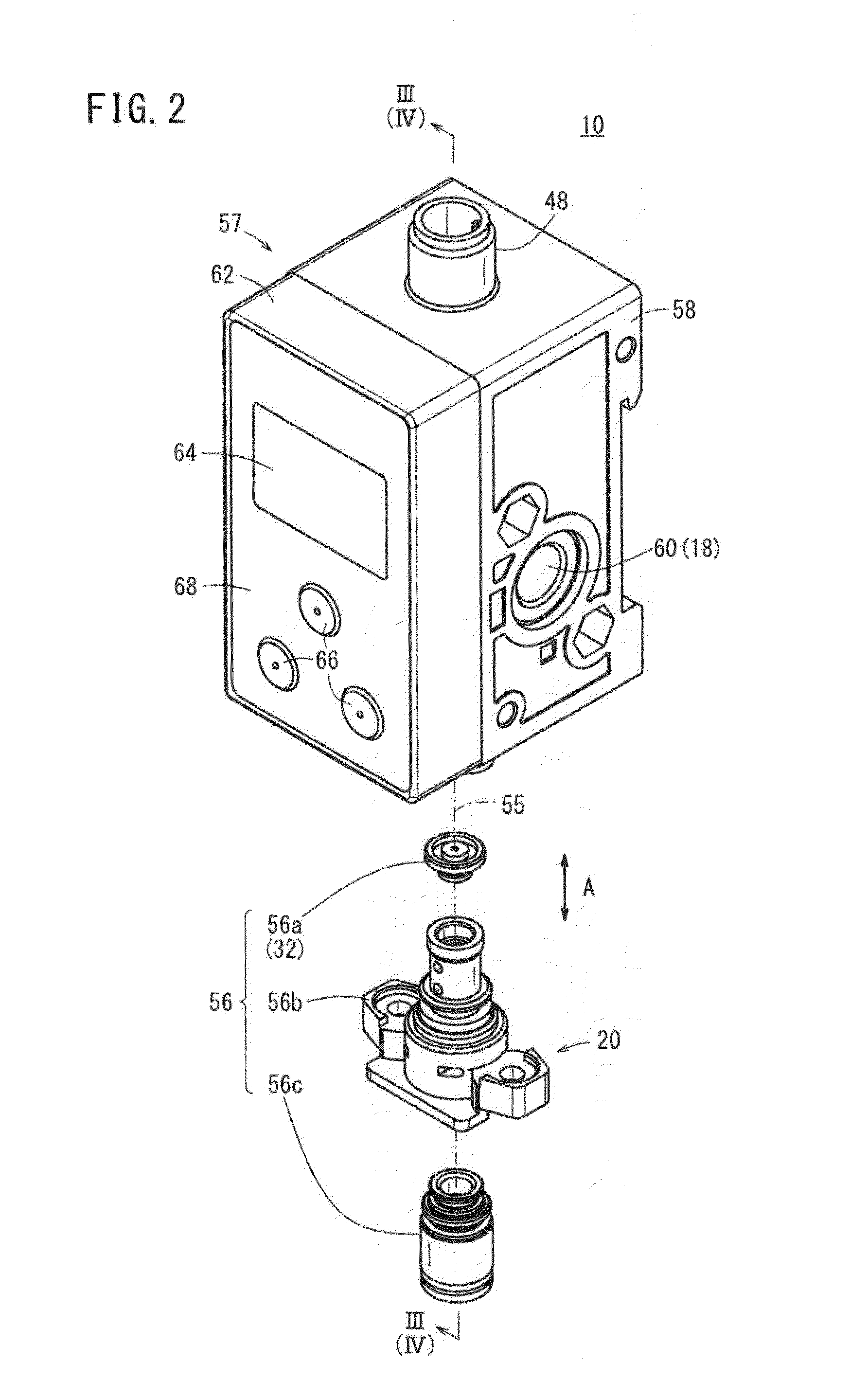

Position detecting device

ActiveUS20140083203A1Detected reliably and accuratelyPromote exchangeConverting sensor output using fluid meansMeasurement/indication equipmentsLocation detectionBiomedical engineering

A position detecting device is equipped with a device main body into which a pressure fluid supplied from a pressure fluid supply source is introduced, and an attaching / detaching mechanism that enables attachment and detachment with respect to the device main body. The attaching / detaching mechanism includes an internal nozzle that delivers, toward the side of a detection nozzle, the pressure fluid supplied to the device main body, and a detection port that supplies, to the detection nozzle, the pressure fluid delivered from the internal nozzle.

Owner:SMC CORP

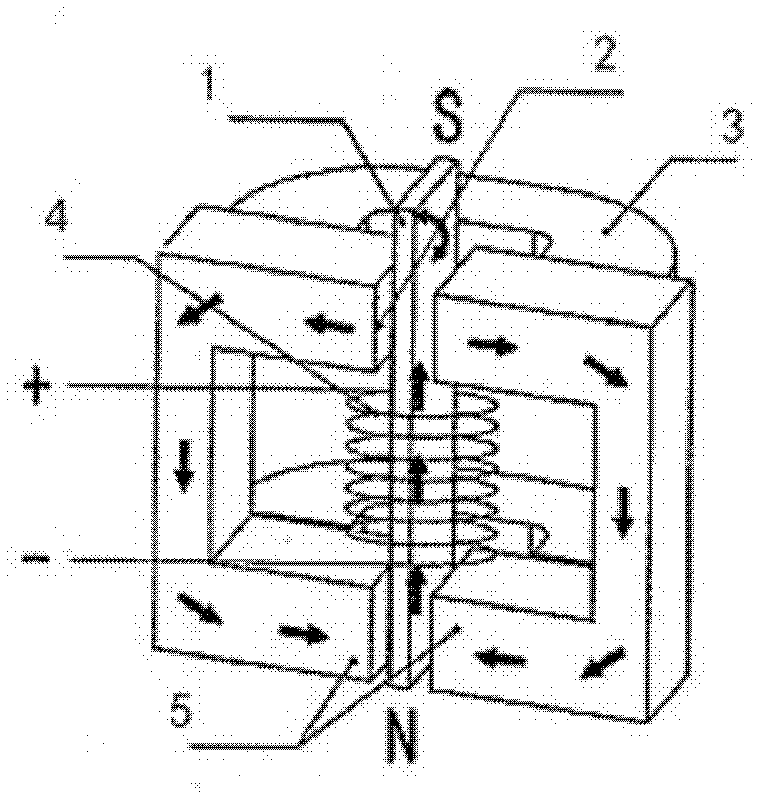

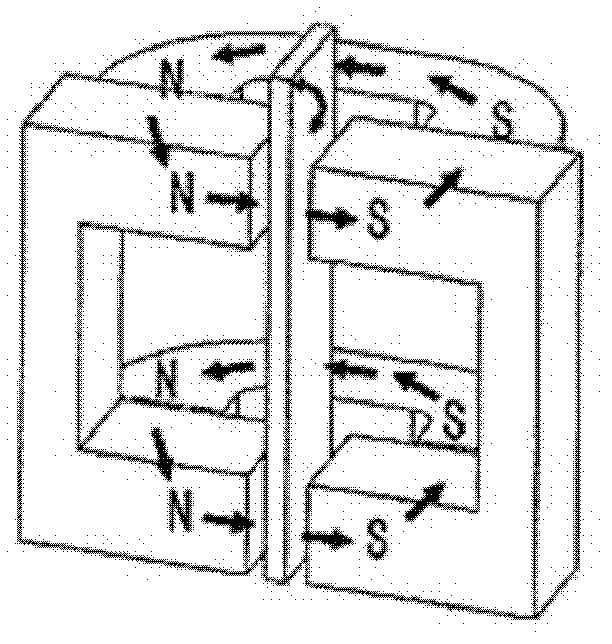

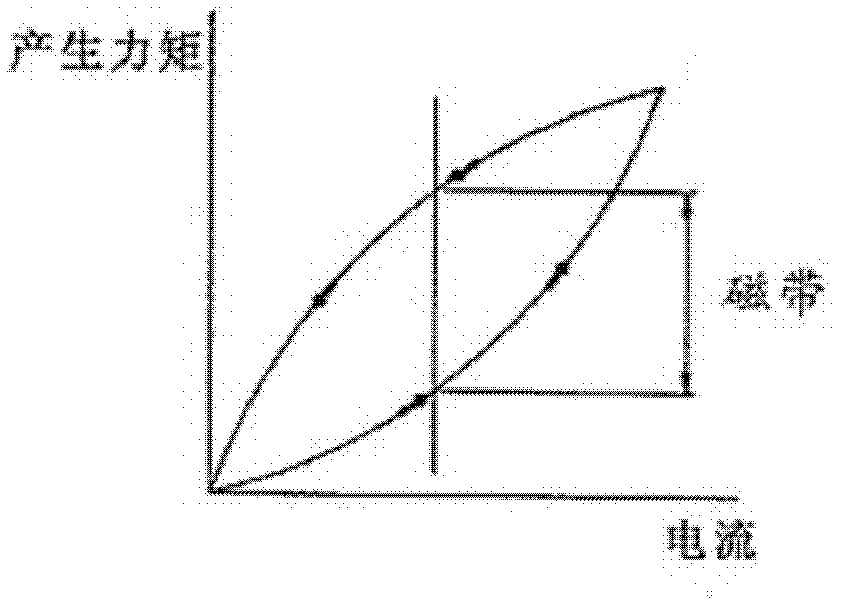

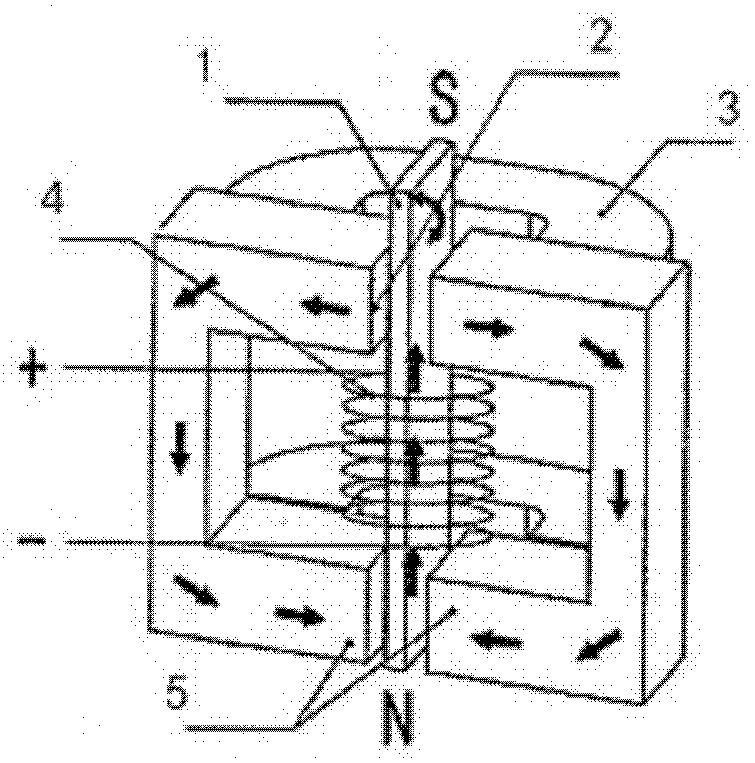

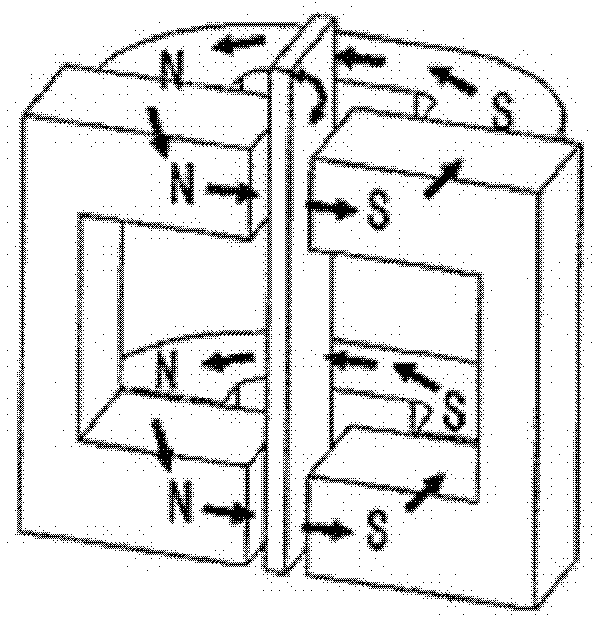

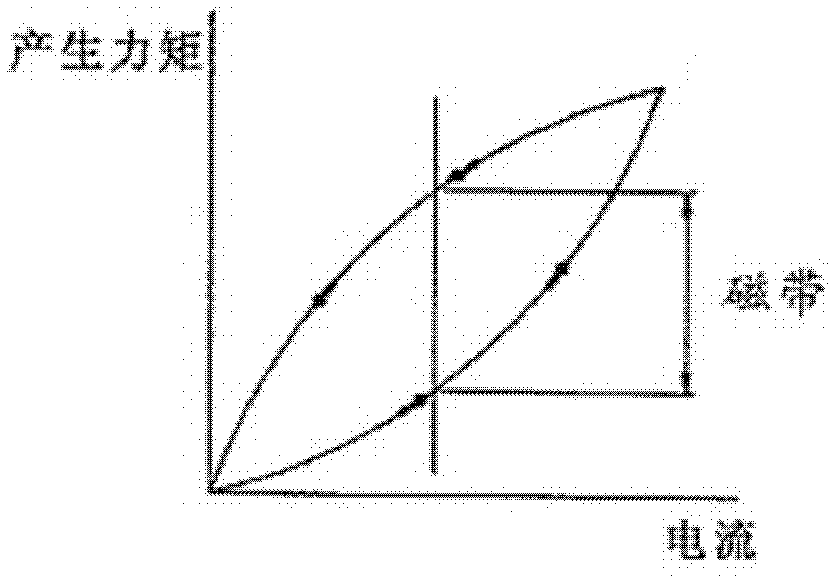

An electro pneumatic converter with low hysteresis characteristic

ActiveCN103166398AReduce hysteresisHigh precision adjustmentConverting sensor output using fluid meansMagnetsHysteresisEngineering

An electro pneumatic converter with low hysteresis. The electro pneumatic converter includes a first stator, a bent plated second stator, and a rotor. The first stator is equipped with a first stator gap and partially wrapped with a coil. The second stator is equipped with a second stator gap on one side end and a permanent magnet which magnetizes the rotor, on the other side. The first and second stators are installed side by side. The rotor's one side is installed near the permanent magnet, and the other end is installed towards the first and second stator gaps, and in between the first and second stator gaps. The above mentioned rotor will be moved according to electric current.

Owner:ROTORK YTC LTD

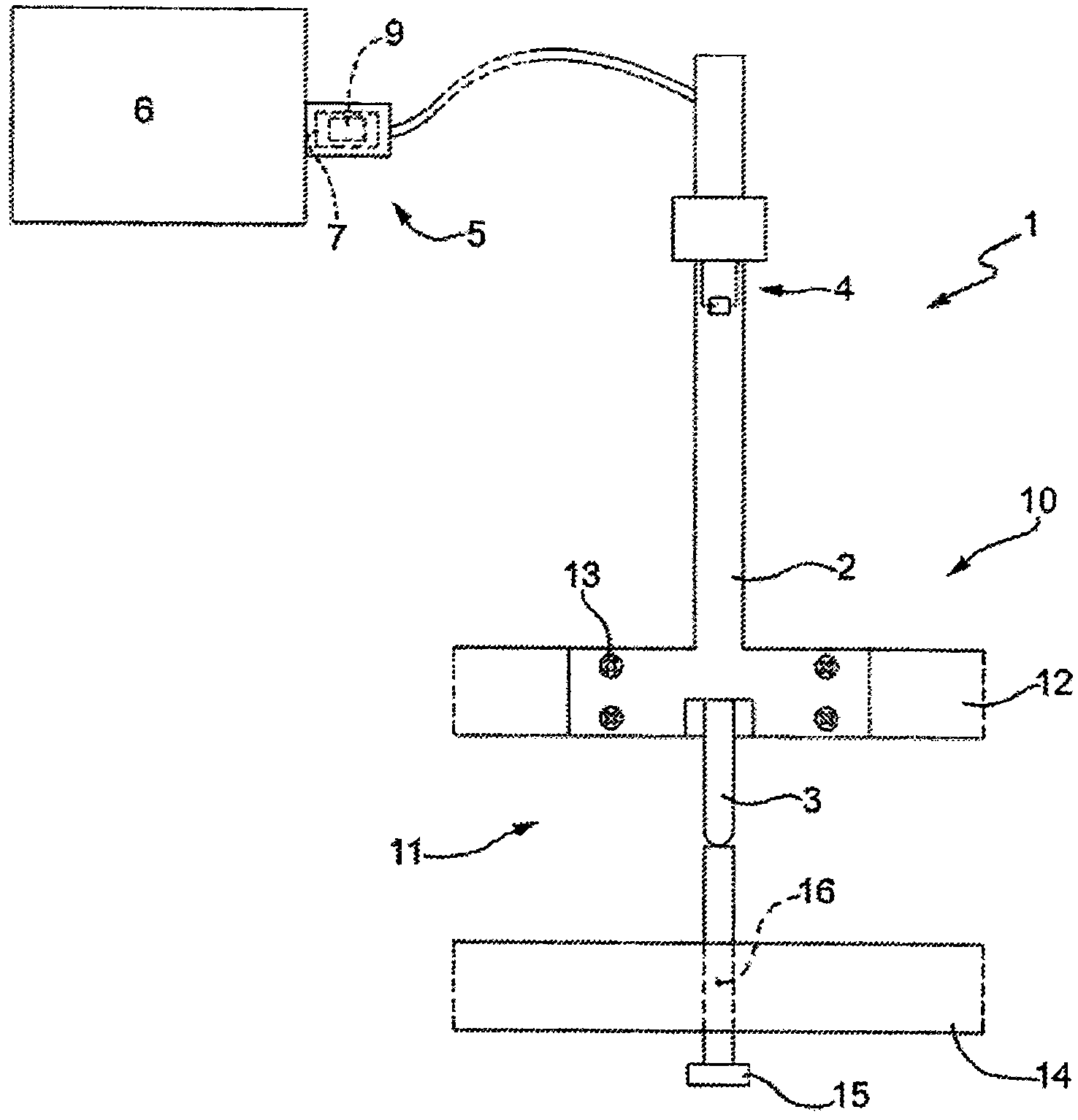

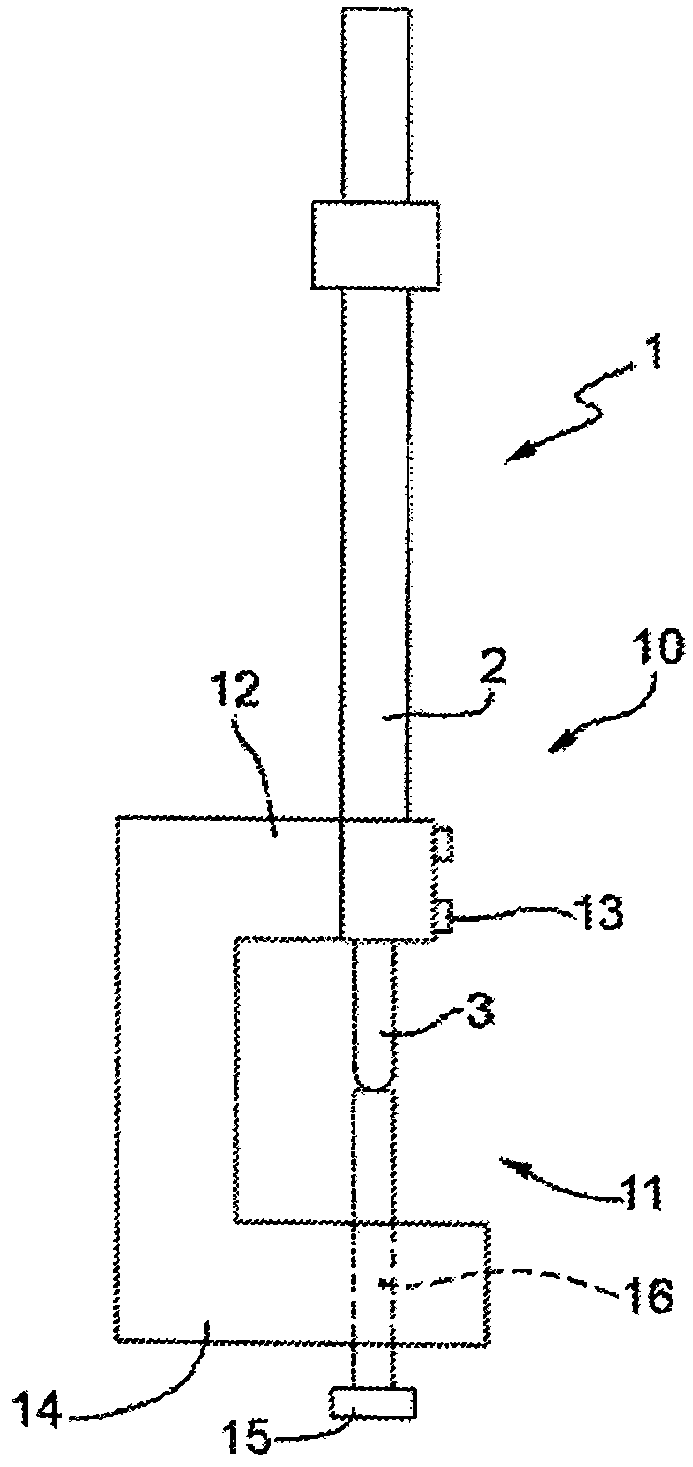

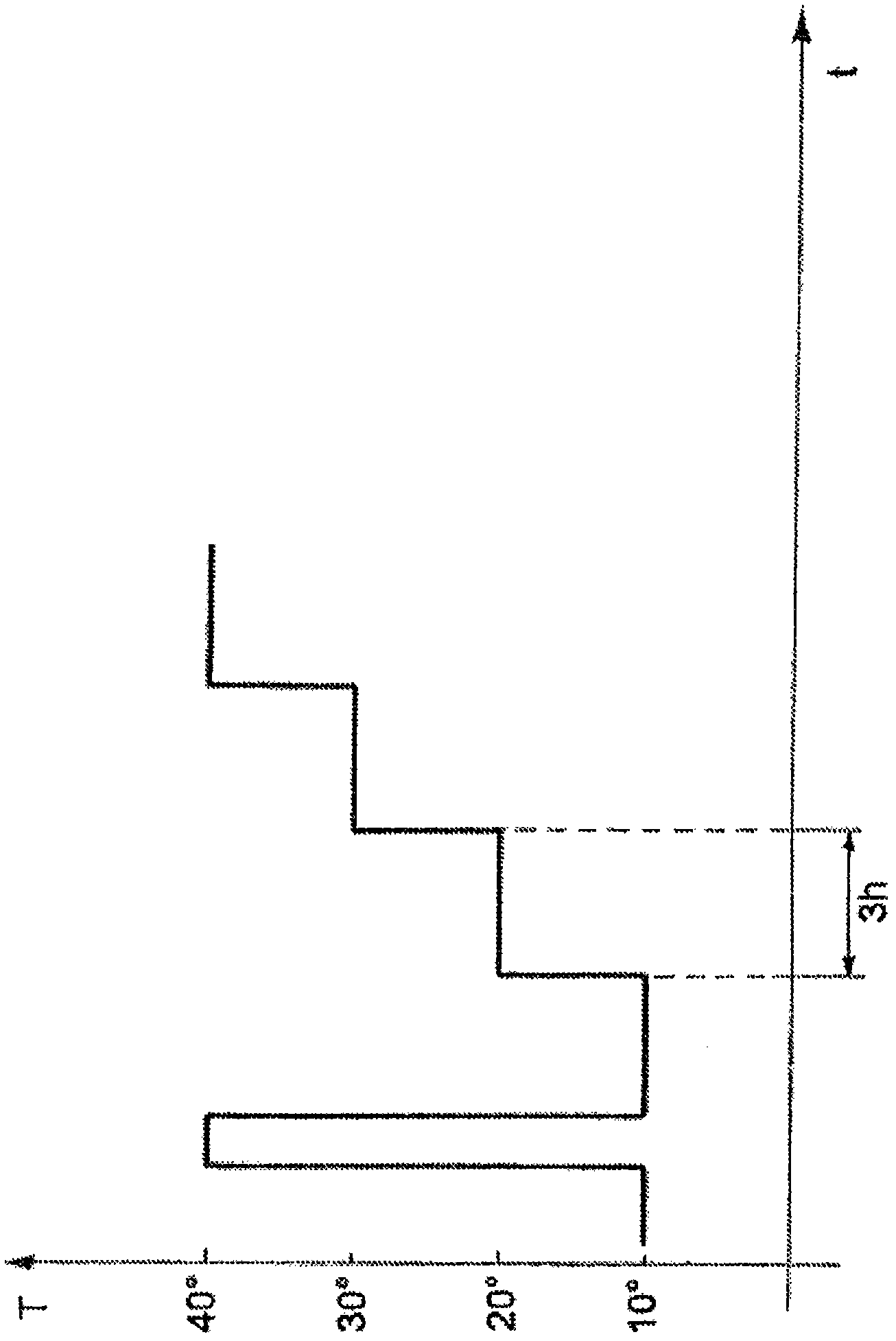

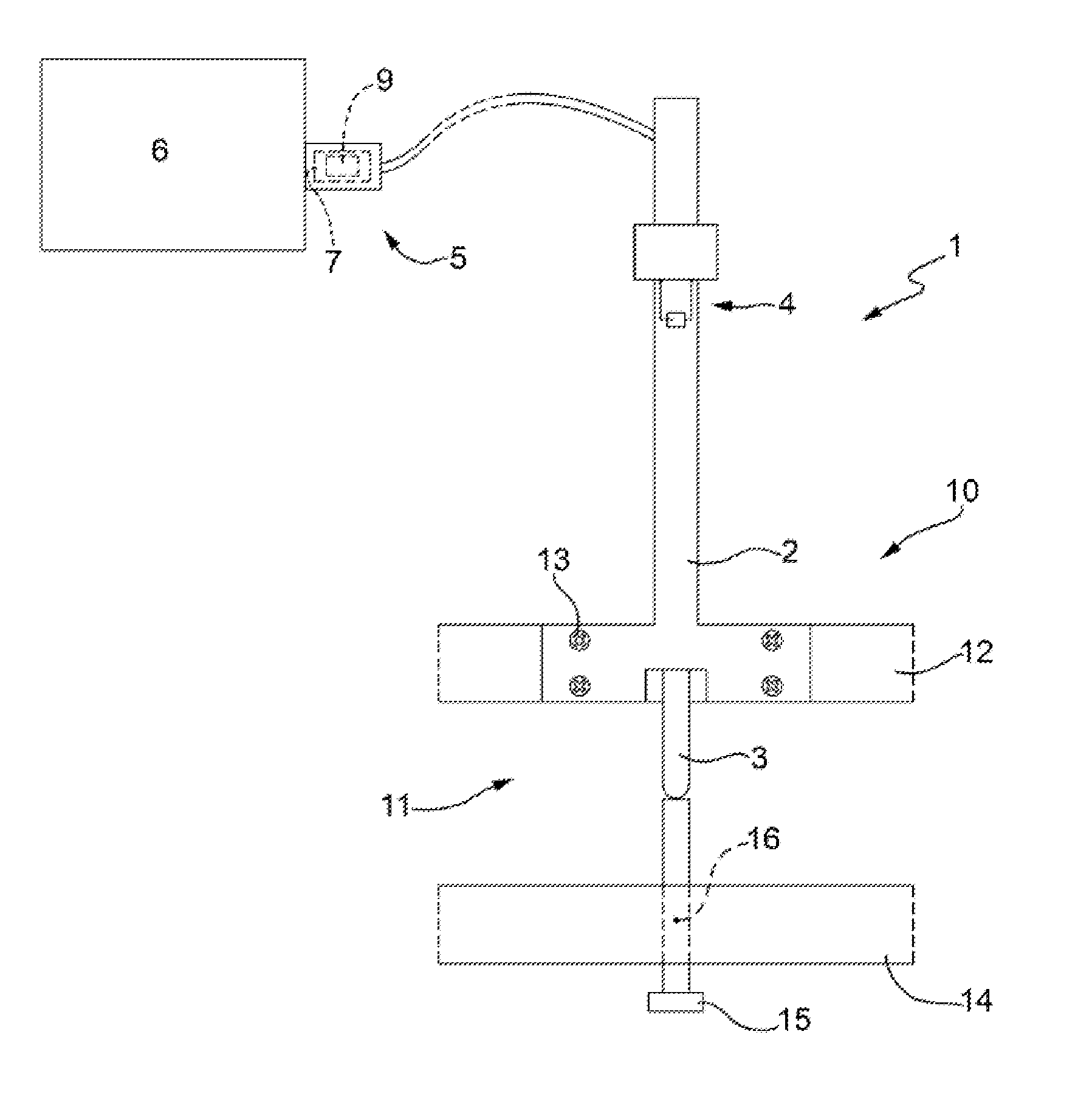

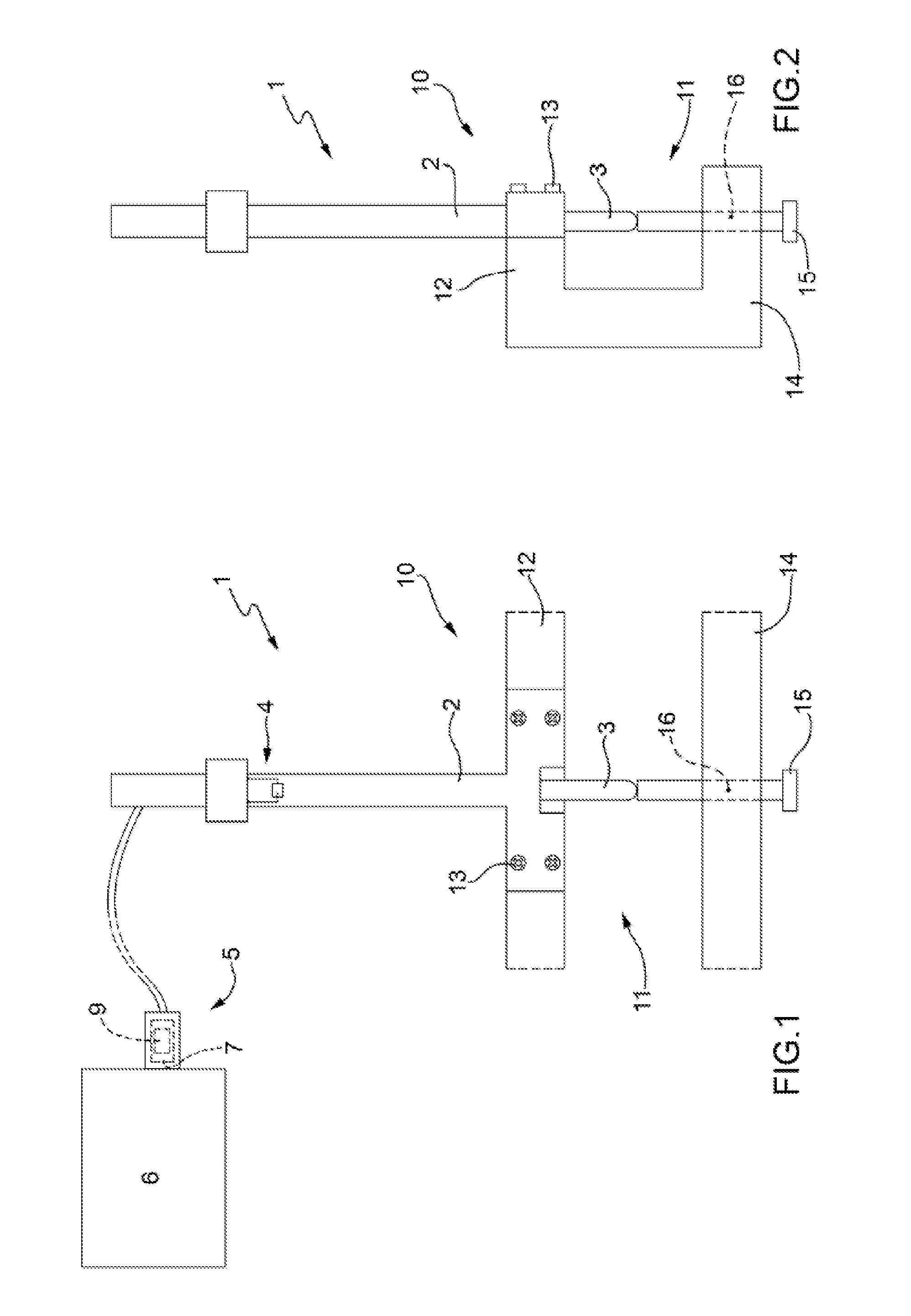

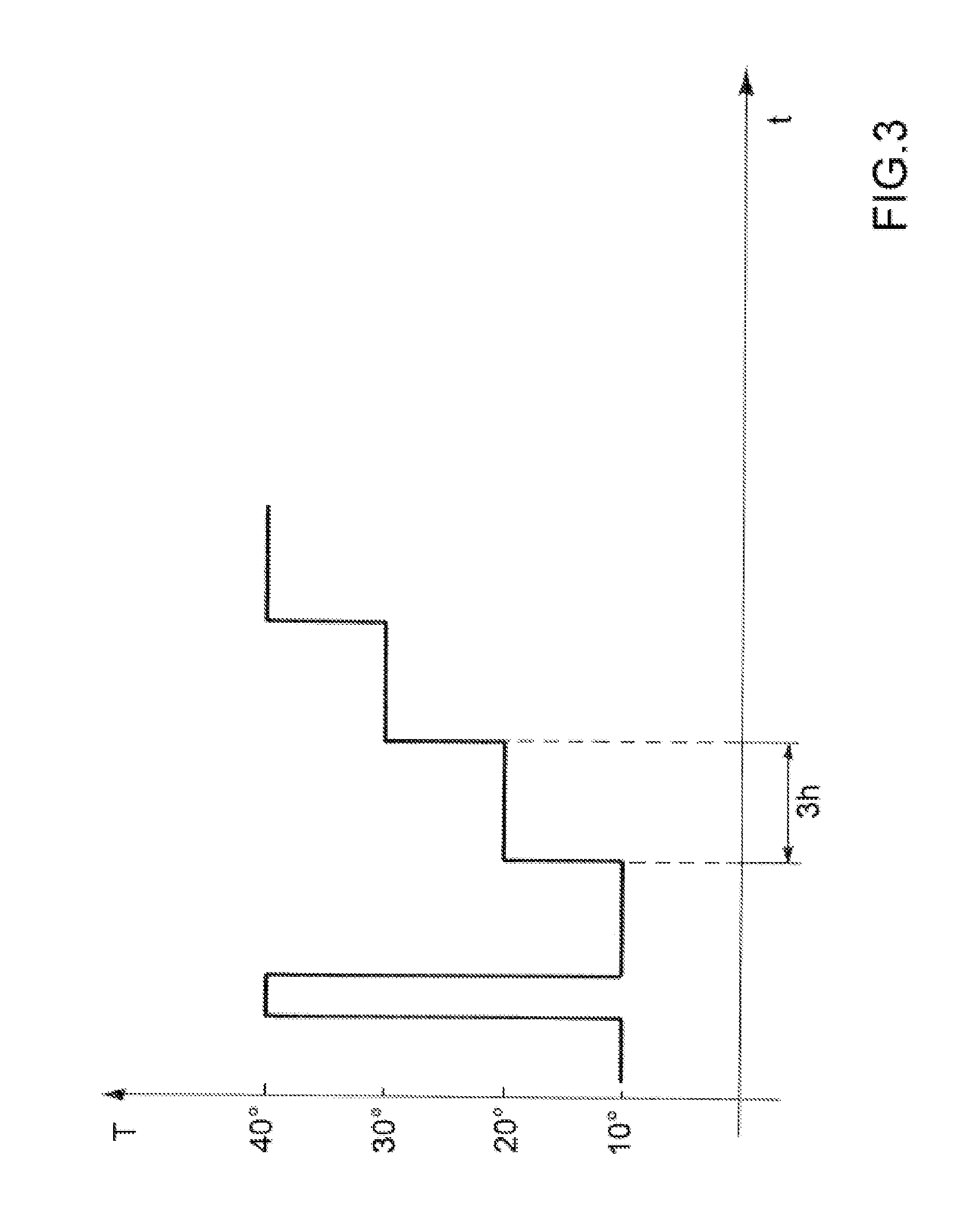

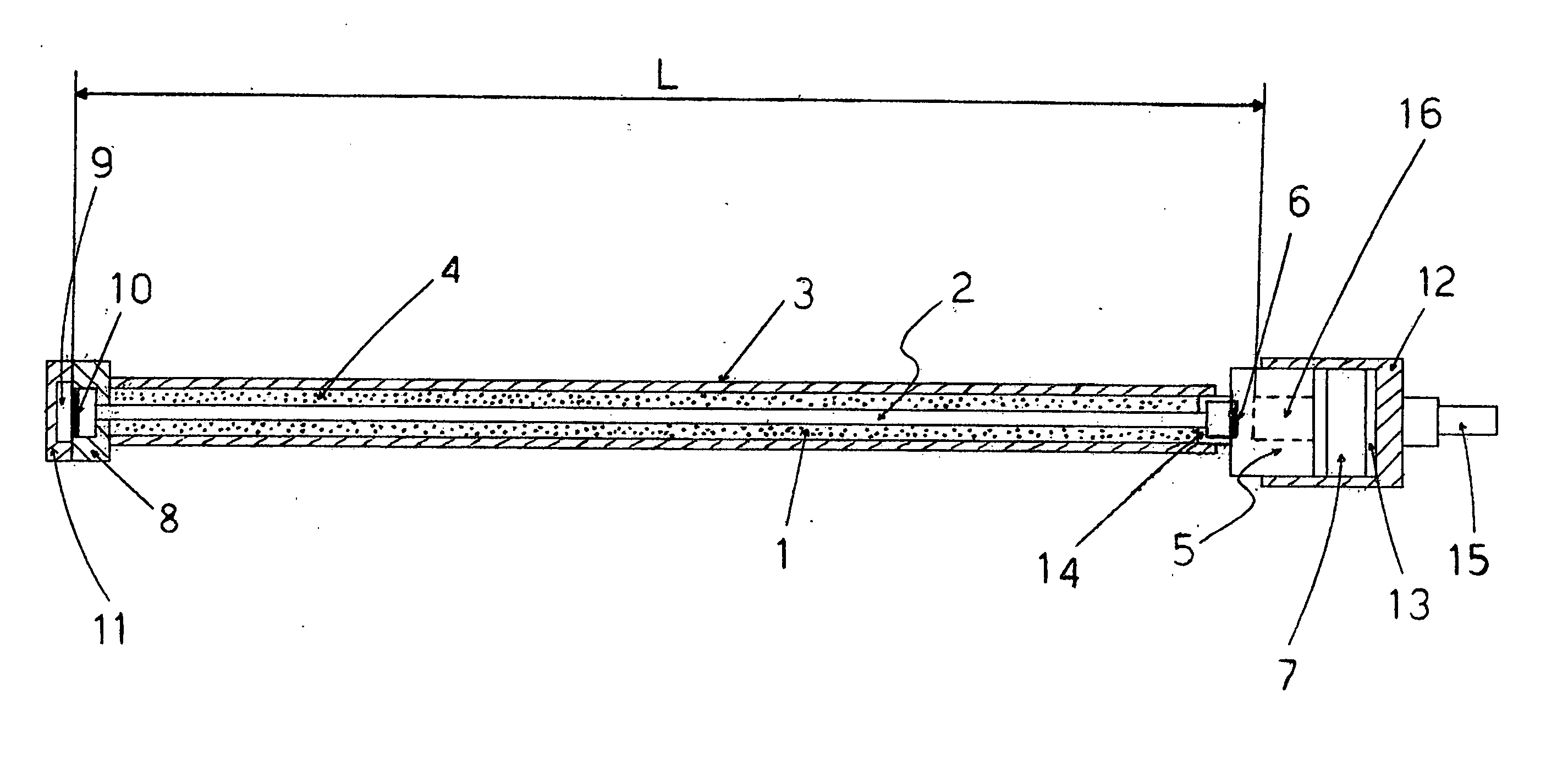

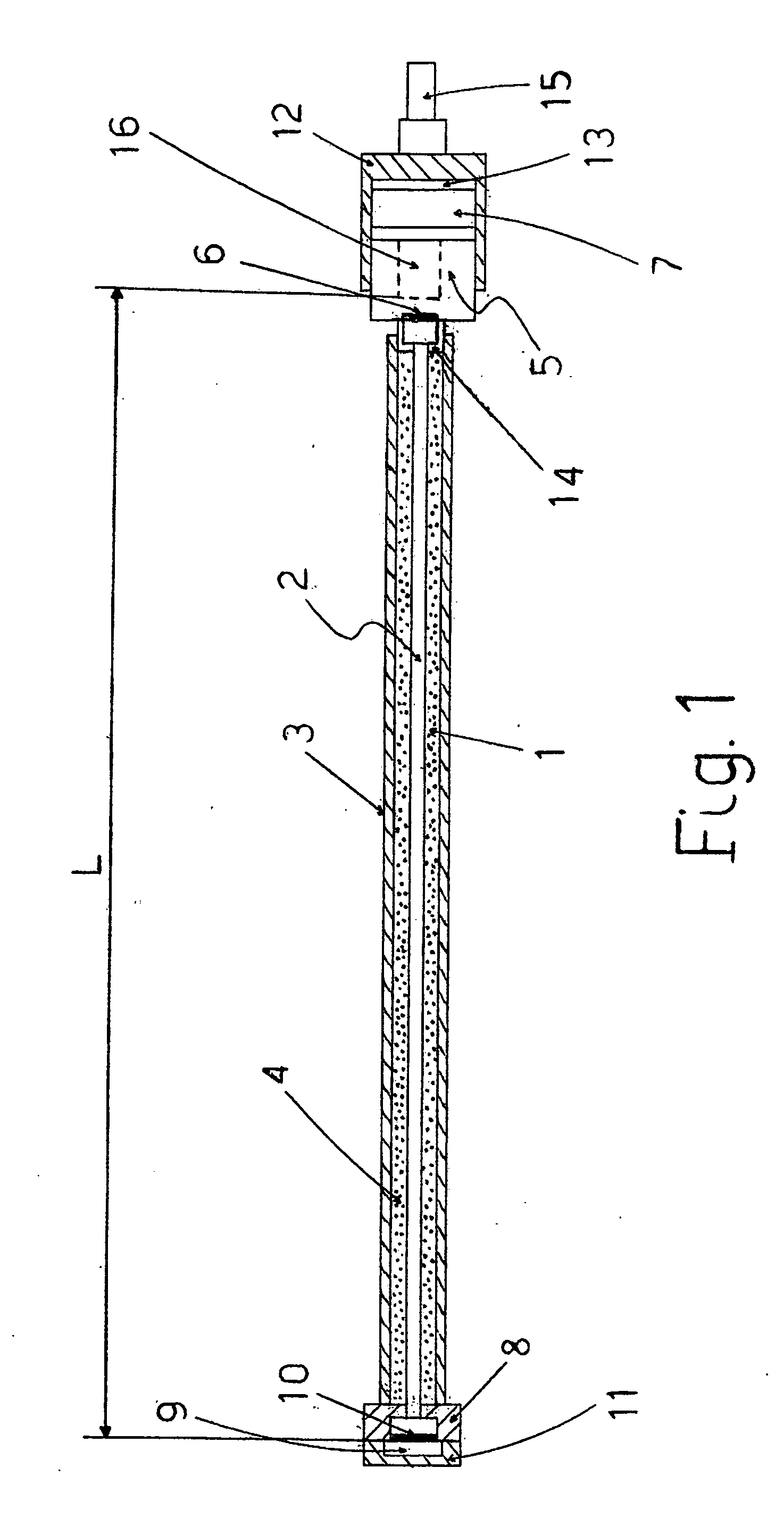

Method for thermally compensating gaging device and thermally compensated gaging station

Thermal drifts compensation method in a gaging device (1) with a transducer; the compensation method includes the steps of : determining and storing, in the course of a calibration operation, values of a thermal compensation coefficient (K) upon variation of a temperature (T) of the gaging device (1); detecting, in the course of a gaging operation, a current reading (X) of the gaging device (1); detecting, in the course of the gaging operation, a current temperature (T) of the gaging device (1); determining, in the course of the gaging operation, the current value of the thermal compensation coefficient (K) by means of the values of the thermal compensation coefficient (K) previously determined and stored in the course of the calibration operation as a function of both the current temperature (T) of the gaging device (1) and the current reading (X) of the gaging device (1); and correcting, in the course of the gaging operation, the current reading (X) of the gaging device (1) by meansof the current value of the thermal compensation coefficient (K).

Owner:MARPOSS SPA

Method for thermally compensating a gaging device and thermally compensated gaging station

InactiveUS20110077890A1Easily and cheaply implementedConverting sensor output using fluid meansCalibration apparatusTransducerSimulation

Thermal drifts compensation method in a gaging device (1) with a transducer; the compensation method includes the steps of: determining and storing, in the course of a calibration operation, values of a thermal compensation coefficient (K) upon variation of a temperature (T) of the gaging device (1); detecting, in the course of a gaging operation, a current reading (X) of the gaging device (1); detecting, in the course of the gaging operation, a current temperature (T) of the gaging device (1); determining, in the course of the gaging operation, the current value of the thermal compensation coefficient (K) by means of the values of the thermal compensation coefficient (K) previously determined and stored in the course of the calibration operation as a function of both the current temperature (T) of the gaging device (1) and the current reading (X) of the gaging device (1); and correcting, in the course of the gaging operation, the current reading (X) of the gaging device (1) by means of the current value of the thermal compensation coefficient (K).

Owner:MARPOSS SPA

Electropneumatic converter with low hysteresis

ActiveCN103166398BReduce hysteresisHigh precision adjustmentConverting sensor output using fluid meansMagnetsHysteresisEngineering

The present invention provides an electropneumatic converter with low hysteresis characteristics. The electropneumatic converter includes a first stator, a second stator having a curved plate shape, and a movable member. The first stator has a first stator gap and a coil wound around a portion of the first stator. One end of the second stator has a second stator gap, and the other end of the second stator is attached with a permanent magnet for magnetizing the moving part. The first stator gap and the second stator gap are arranged next to each other. One end of the moving part is adjacent to the permanent magnet, and the other end of the moving part extends through the first stator gap and the second stator gap. The traveling member is provided to swim in the first stator gap and the second stator gap according to the current applied to the coil.

Owner:ROTORK YTC LTD

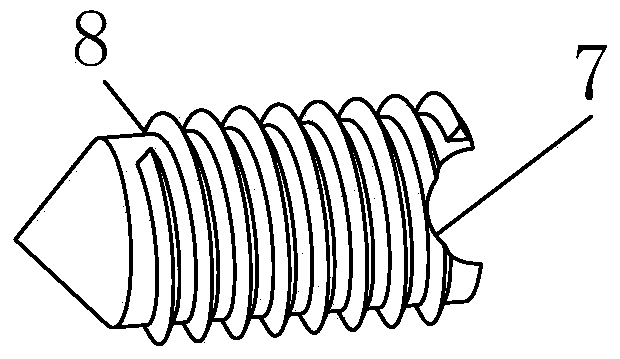

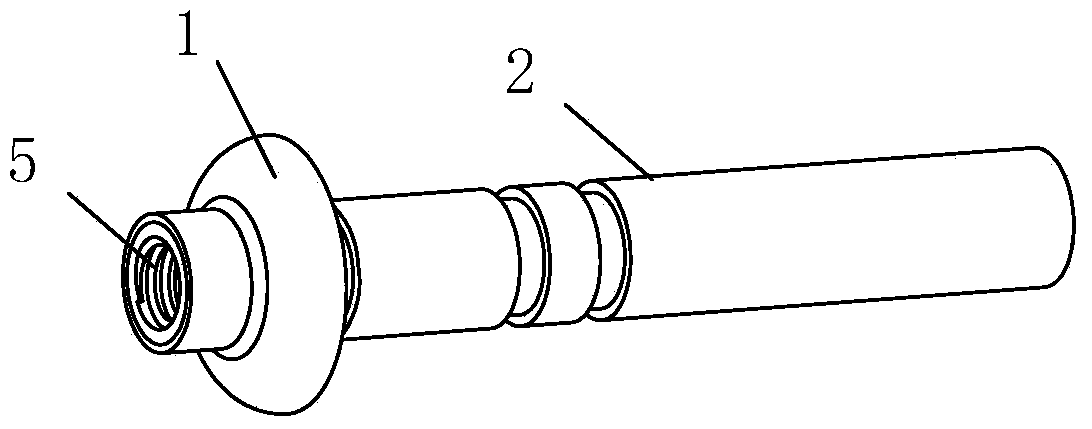

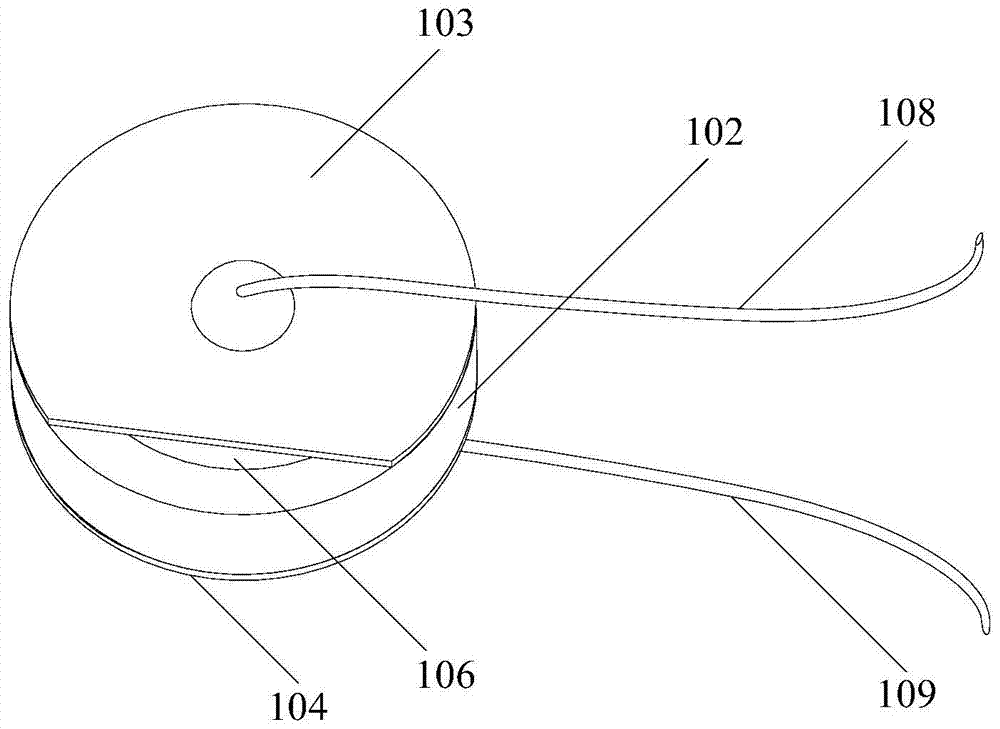

Eddy current type sensor measuring head

InactiveCN104374415AAvoid damageAvoid collisionConverting sensor output using fluid meansEddy currentEngineering

The invention relates to the technical field of pneumatic sensors, in particular to an eddy current type sensor measuring head. The eddy current type sensor measuring head comprises a volute, the diameter of the upper end of the volute is large, the diameter of the lower end of the volute is small, an input port is formed in the large-diameter upper end of the volute in the tangent direction of the volute, the small-diameter lower end is an exhaust port, an axis pipe is arranged at the axis position of the volute from top to bottom, the upper portion of the axis pipe extends out of the top face of the volute to form an output port, the output port is provided with a corrugated pipe connected with a sensor, the lower portion of the axis pipe retracts in the volute, the lower end face of the axis pipe is not flush with the bottom end face of the volute, the outer diameter of the axis pipe is smaller than the diameter of the lower end of the volute, and the measuring head is connected with the sensor through the corrugated pipe. The sensor is protected against damage when impacted, the measuring head feeds back measurement information in an eddy current mode, and measurement is sensitive and accurate.

Owner:CHANGZHOU HUAXIAN HARDWARE FACTORY

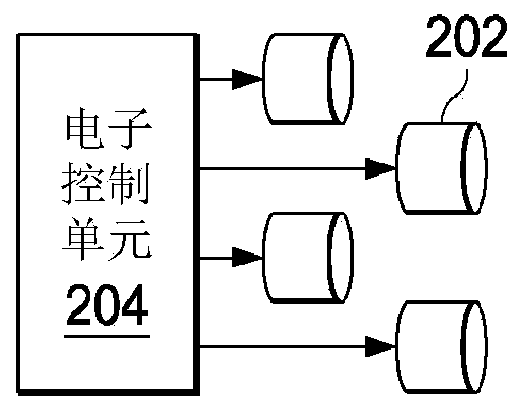

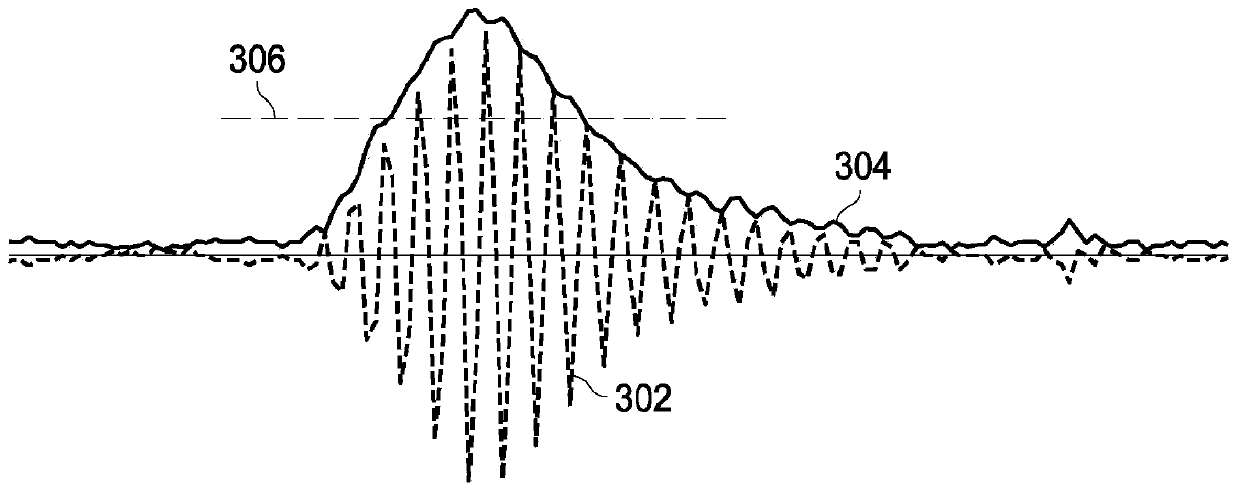

Threshold generation for coded ultrasonic sensing

PendingCN110780301AConverting sensor output using fluid meansAcoustic wave reradiationEnvironmental noiseTransducer

Embodiments of the present application relate to threshold value generation for coded ultrasonic sensing. In an ultrasonic detection system that uses frequency-modulation coding to distinguish emittedbursts from multiple transducers, a receiver (600) associated with a transducer uses dynamic thresholding to discriminate valid echoes (906) from system and environmental noise in multiple envelope signals produced by multiple correlators (608, 610). The time-varying dynamic thresholds are generated from the mean of noise in a respective envelope derived from the output of a respective correlator. Multiple thresholds can be combined together (620) such that a single time-varying threshold is applied to all correlators' envelopes. Such thresholding has the benefits of a constant false-alarm rate with regard to detection of echoes (as opposed to false triggering from noise), and, owing to finer-resolution and adaptive thresholds, can detect targets or obstacles as further distances and withgreater time responsiveness.

Owner:TEXAS INSTR INC

Device for detecting the position of a mobile element to which it is coupled and related mobile element

InactiveUS20060255792A1Accurate and reliable detectionHighly aggressiveProduction of permanent recordsConverting sensor output using fluid meansEngineeringOperant conditioning

A device for detecting the position occupied by a mobile element operatively associated therewith in relation to a reference position, comprising at least one container containing a fluid and a detector device operatively connected to said container, said detector device being configured so as to provide a signal to indicate the actual position of said mobile element as a function of at least one parameter recorded thereby and indicative of an operative condition of the fluid, or of a condition of operative interaction between the fluid and the detector device.

Owner:ABB SPA

Injection molding quality testing method and testing device for L-shaped water pipes used in refrigerator ice-making water storage boxes

ActiveCN110530587BThe test result is accurateAvoid measurement errorsMachine part testingMeasurement of fluid loss/gain rateWater storageIcebox

The invention relates to a method and a detection device for the injection molding quality of an L-shaped water pipe used in an ice-making water storage box of a refrigerator. The detection method includes the following steps: recording the air pressure A when the air source is not connected to the water pipe to be tested; Connect to one end of the water pipe to be tested, and record the air pressure B of the air source; compare the first difference between air pressure B and air pressure A with the standard deviation range, if it is within the range, it is a qualified product, and if it exceeds, it is an unqualified product ; The other end of the water pipe to be tested is closed, record the air pressure C in the water pipe to be tested, compare the second difference between the air pressure C and the standard value with the first standard deviation, if it is greater, it is an unqualified product; if it is less than, Then stop the air intake, record the air pressure D, compare the third difference between the air pressure D and the air pressure C with the second standard deviation, if it is less than, it is a qualified product, if it is greater, it is an unqualified product. Through the invention, the detection result of the injection molding quality of the water pipe is accurate and the detection speed is fast.

Owner:苏州向心圆电子科技有限公司

An amplifying device for continuously amplifying displacement

InactiveCN103196476BSimple structureLow costConverting sensor output using fluid meansHydraulic cylinderEngineering

The invention relates to a displacement amplification device, and aims at resolving the problems that a device in the prior art is complex in structure and high in cost, and occupied installation space by a displacement amplification mechanism and other devices is large. The displacement amplification device comprises a lever structure and a hydraulic cylinder mechanism, wherein the lever structure comprises an ejection column, a lever and a support shaft; and the hydraulic cylinder mechanism comprises a first piston, a second piston, a connecting rod, hydraulic oil, a hydraulic cylinder and an oil outlet tube. The lever penetrates through the support shaft, the axis of the lever is vertical to the axis of the support shaft, the upper end of the ejection column is arranged below the left end of the lever, one end of the oil outlet tube is communicated with the middle portion of the lower end face of the hydraulic cylinder in a sealed mode, the lower end of the connecting rod is fixedly connected with the upper end face of the first piston, the first piston is arranged in a cylinder body of the hydraulic cylinder, the upper end of the connecting rod is arranged below the right end of the lever, the second piston is arranged in the other end of the oil outlet tube, and hydraulic oil is filled both in the hydraulic cylinder and the oil outlet tube. The displacement amplification device is used in the field of mechanical tools.

Owner:HARBIN INST OF TECH

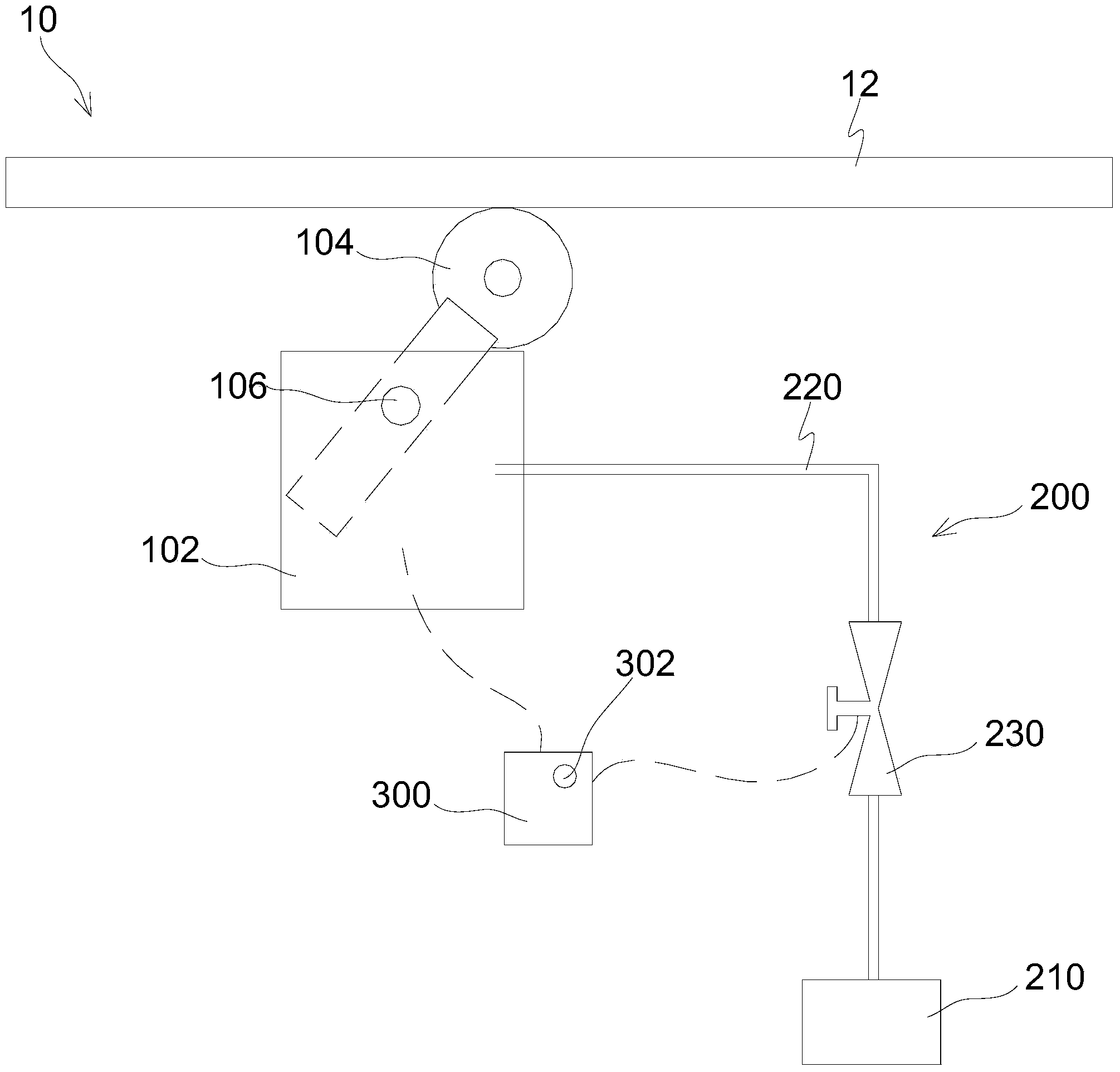

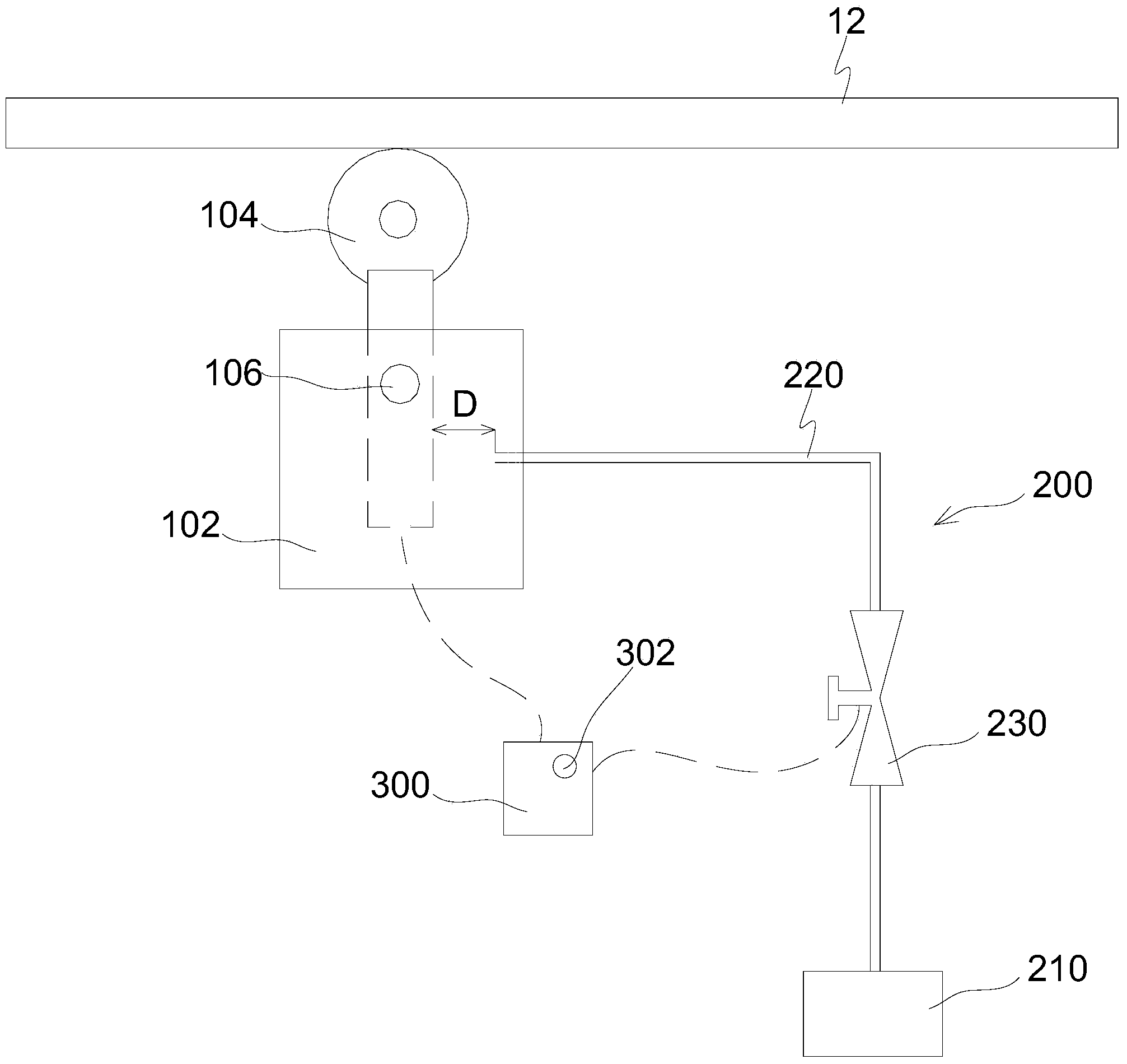

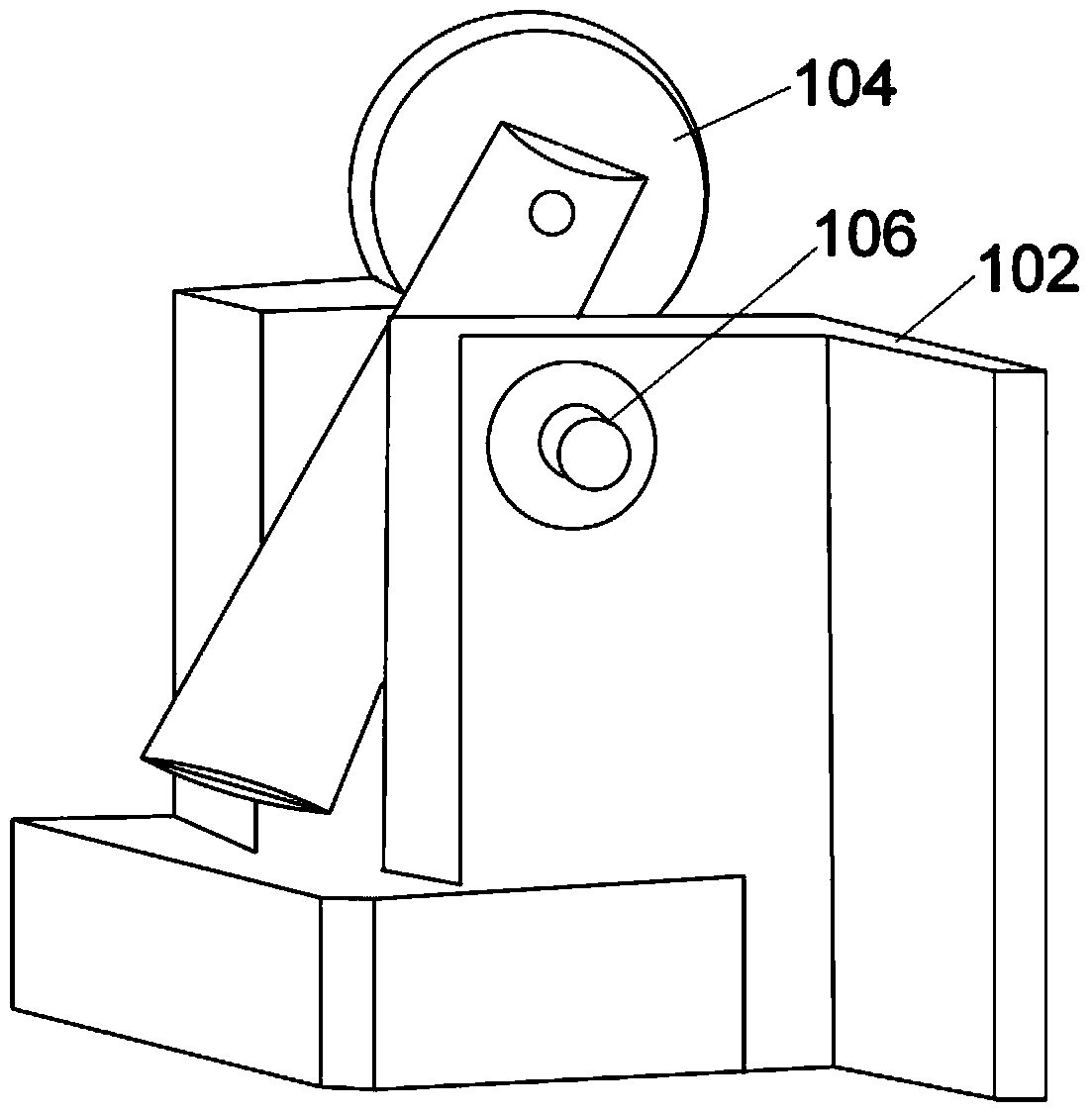

Swing type sensor module

InactiveCN103776477AGuaranteed resetResilience is sufficientOperating means/releasing devices for valvesMeasurement apparatus componentsDowntimeRestoring force

The invention discloses a swing type sensor module (10) which comprises a support (102), a sensor oscillator (104) and a liquid spraying device (200). The sensor oscillator (104) is installed on the support (102) in a swing mode, and the liquid spraying device (200) is used for spraying liquid to the sensor oscillator (104). Due to the fact that the liquid spraying device sprays the liquid to the sensor oscillator, even if the sensor oscillator (104) is not used for a long time, the phenomenon that the liquid is dried by air and adheres or restoring force is not enough occurs, the liquid sprayed out by the liquid spraying device can give power to the sensor oscillator to enable the sensor oscillator to be disengaged from the adhesion state and have enough restoring force, and it is ensured that the vibrator can be restored. Thus, when a glass substrate passes through, the state of the glass substrate can be sensitively reflected, normal transmission of signals can be ensured, downtime and overhauling are reduced, and the product yield and the equipment utilization are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

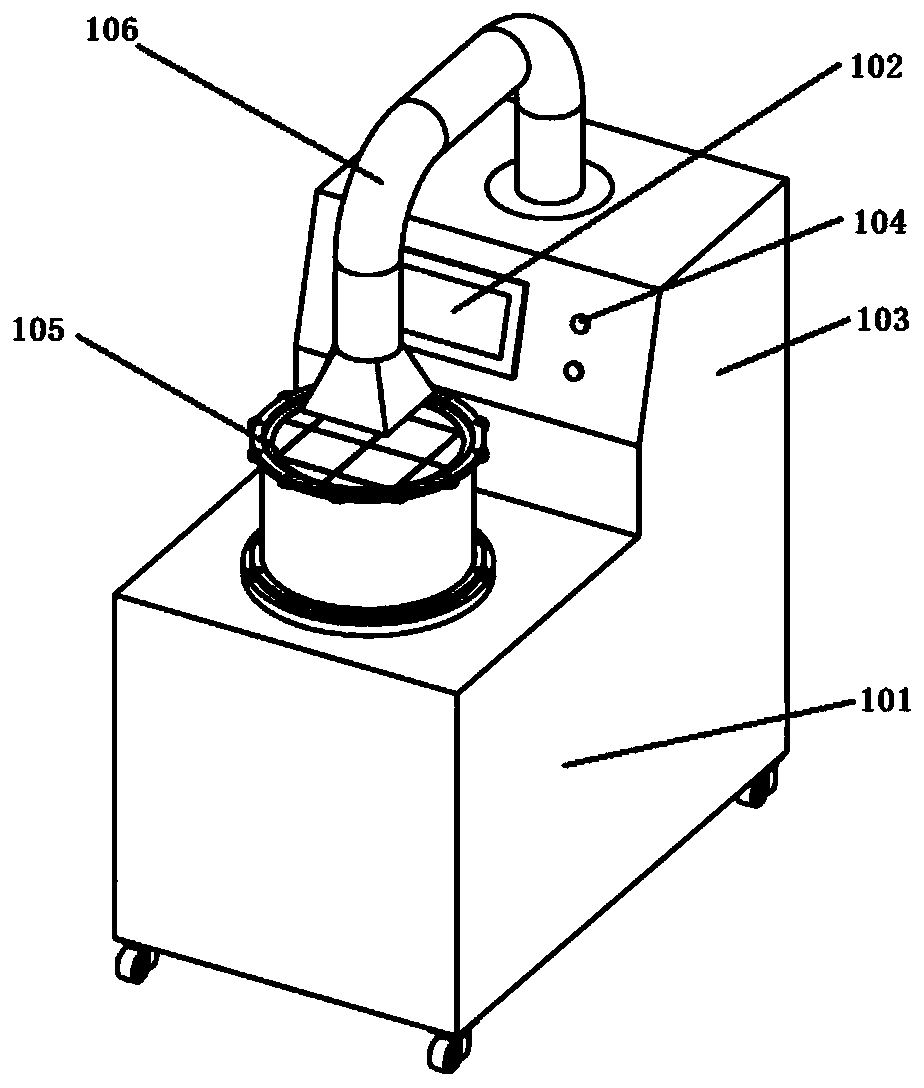

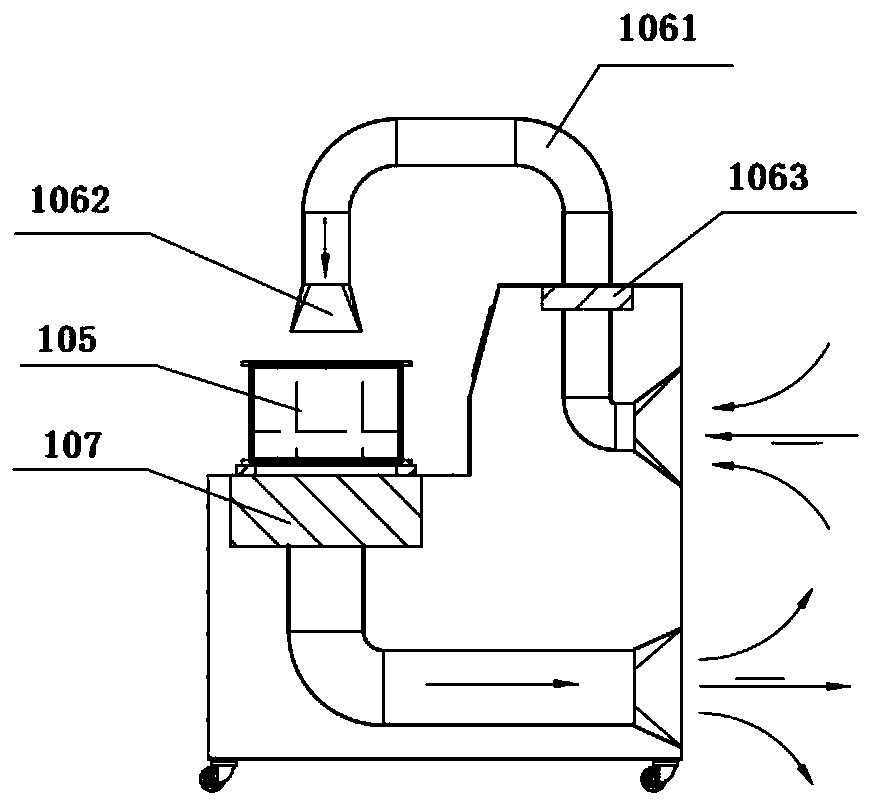

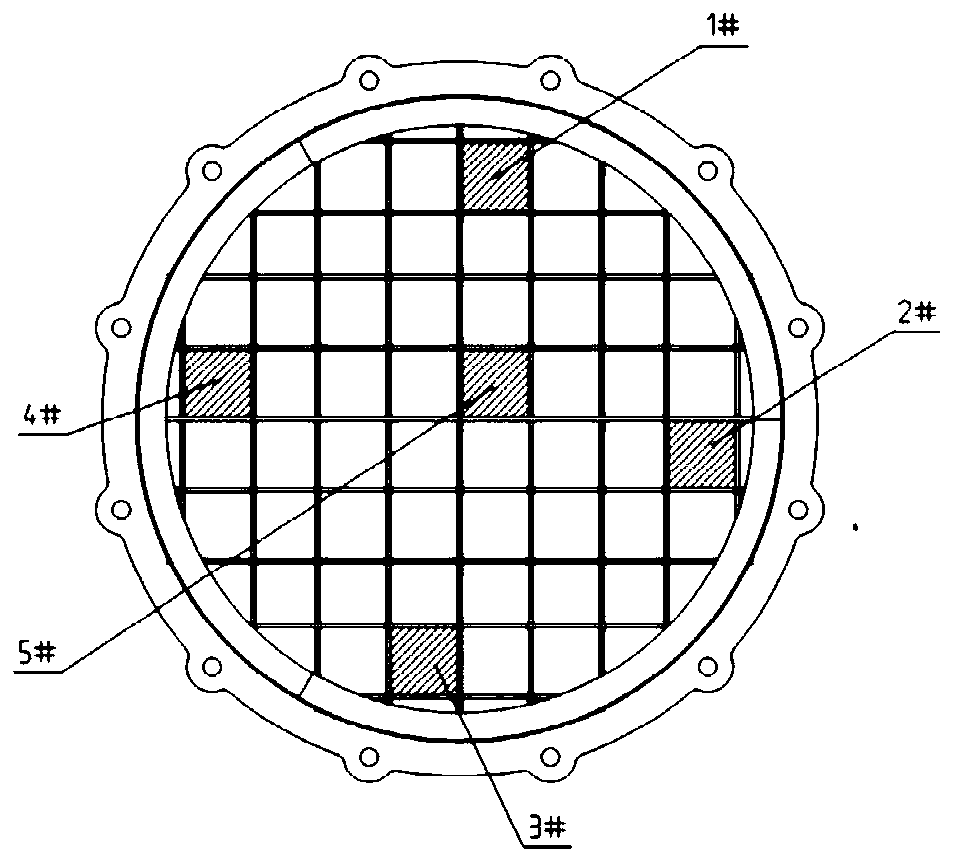

Function tester for DPF/GPF carrier

InactiveCN111473812ALearn about congestionEfficiently provideConverting sensor output using fluid meansFluid speed measurementFunctional testingAir velocity

The invention discloses a function tester for a DPF / GPF carrier. The function tester is characterized by comprising a cabinet body, an air draft device arranged in the cabinet body and a test arm connected with the cabinet body. The cabinet body comprises a cabinet body I used for placing a DPF / GPF carrier and a cabinet body II provided with a functional panel, the air inlet end of the air draft device is communicated with a test carrier, the air outlet end of the air draft device is communicated with the outside through the side wall of the cabinet body, the test arm is communicated with theoutside through the side wall of the cabinet body, and an anemograph is arranged in the test arm. By utilizing the technical scheme provided by the invention, the wind speed in the DPF / GPF to be measured, especially the wind speed in part of small holes, can be effectively provided in real time, so that the blockage condition of the DPF / GPF can be integrally or locally known based on the wind speed, and a reliable reference standard is provided for maintenance of the DPF / GPF.

Owner:杭州一轩科技有限公司

pneumatic sensor

ActiveCN105203139BSimple manufacturing processIncrease the output voltageConverting sensor output using fluid meansElectric signalAirflow

The invention discloses a pneumatic sensor, which has an air inlet and an air outlet. The pneumatic sensor includes: a first friction component, a housing, a second friction component and a third friction component; wherein, the housing has a hollow hollow with a preset shape structure to form an airflow passage, and the airflow passage communicates with the air inlet and the air outlet, so that the airflow enters the airflow passage through the air inlet and flows out through the air outlet; the first friction part is arranged in the airflow passage, and the second and third friction parts Set at a position where it can be in contact with the first friction part; when the airflow enters the airflow channel through the air inlet, the first friction part will rub against the second and / or third friction part respectively due to the action of the airflow and generate electrical signals, the second and The third friction component includes an electrical signal output of the pneumatic sensor. The pneumatic sensor can simplify the manufacturing process of the existing pneumatic sensor, increase the driving force of the air flow on the first friction part in the pneumatic sensor, and further improve the working sensitivity and stability of the pneumatic sensor.

Owner:NAZHIYUAN TECH TANGSHAN LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com