Swing type sensor module

A sensor assembly, swinging technology, applied in measuring instrument assemblies, using fluid devices to transmit sensing components, instruments, etc., can solve problems such as inability to transmit signals normally, reduce product yield, vibrator adhesion and recovery force, etc., to improve product quality. Yield rate and equipment utilization rate, reduce downtime and maintenance, ensure the effect of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

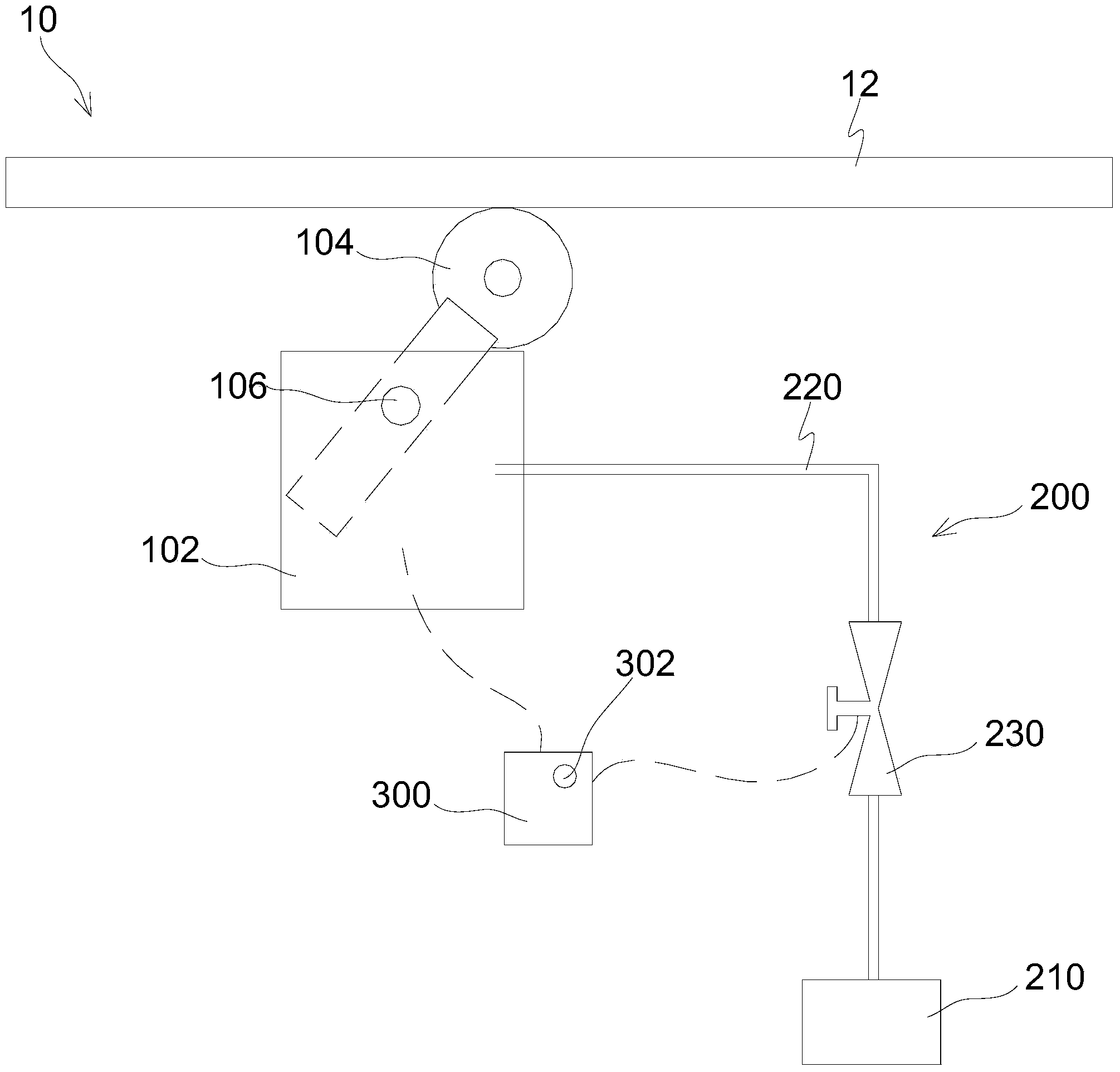

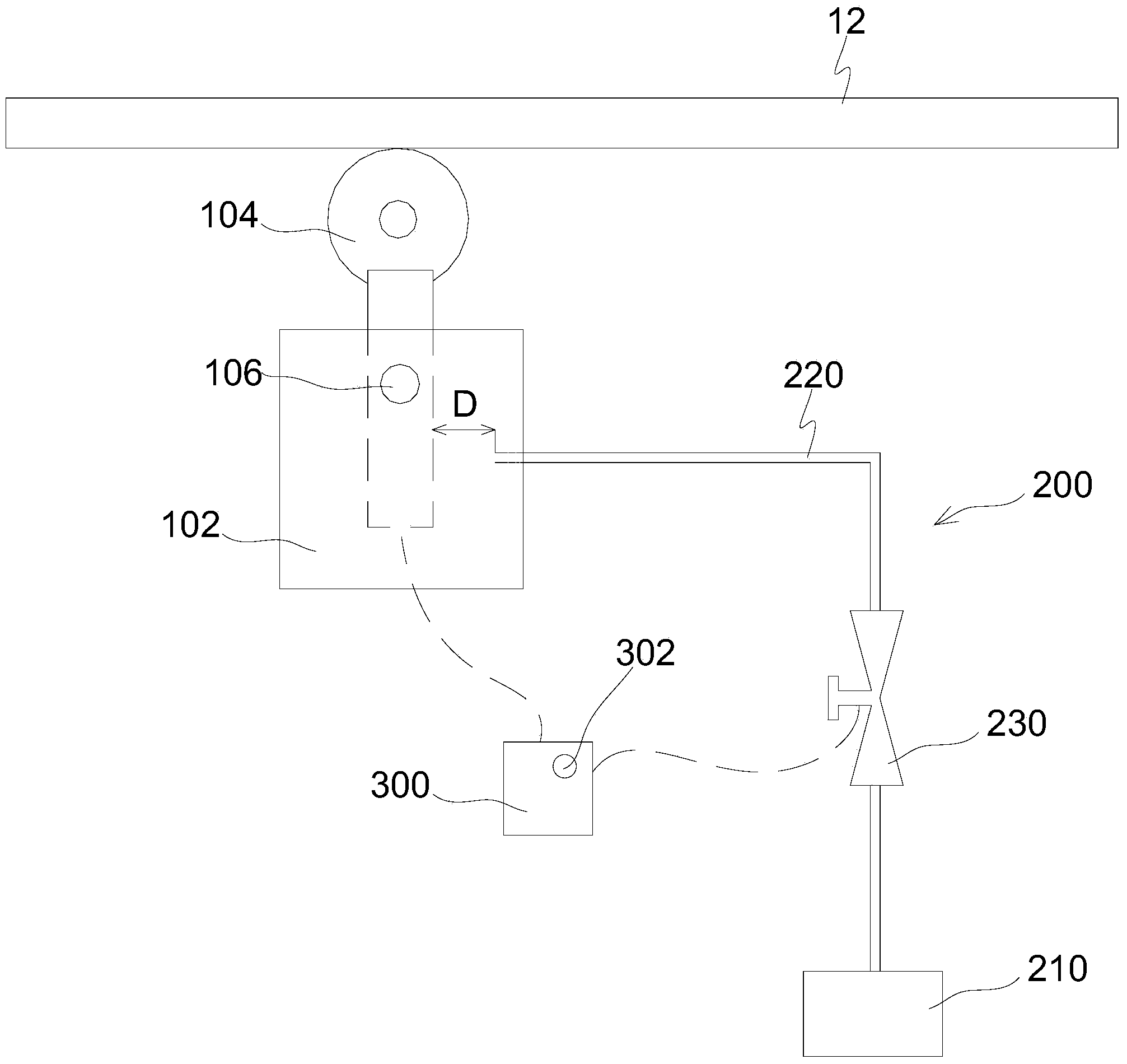

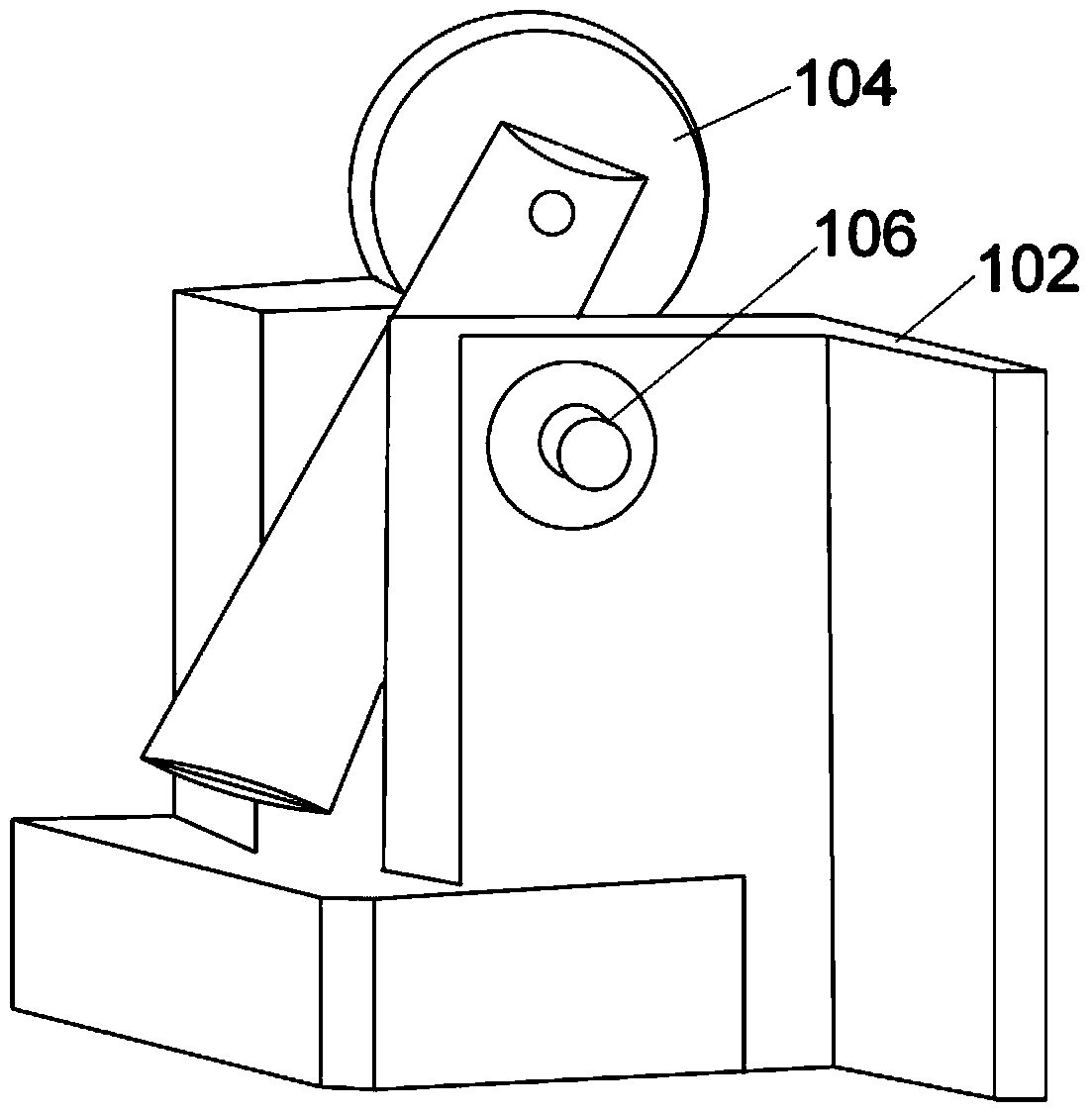

[0020] like figure 1 As shown, the swing sensor assembly 10 of this embodiment includes a bracket 102, a sensor vibrator 104, a control unit 300 and a liquid spray device 200, the sensor vibrator 104 is swingably mounted on the bracket 102, and the liquid spray device 200 is used to spray liquid to the sensor vibrator 104 . like image 3 As shown, the bracket 102 is provided with a pin shaft 106 , and the sensor vibrator 104 is connected to the pin shaft 106 in a manner of reciprocating swing around the pin shaft 106 .

[0021] In this embodiment, the liquid spray device 200 is a water spray device. Wherein, the liquid injection device 200 includes a liquid storage tank 210 , an infusion pipeline 220 and a control valve 230 arranged on the infusion pipeline 220 . The control valve 230 is preferably an electromagnetic control valve. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com