Pneumatic sensor

A pneumatic sensor and air flow technology, applied in the field of sensors, can solve the problems of false triggering, poor sensitivity and stability, complicated manufacturing process, etc., and achieve the effect of simplifying the manufacturing process, improving the driving force, and increasing the vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

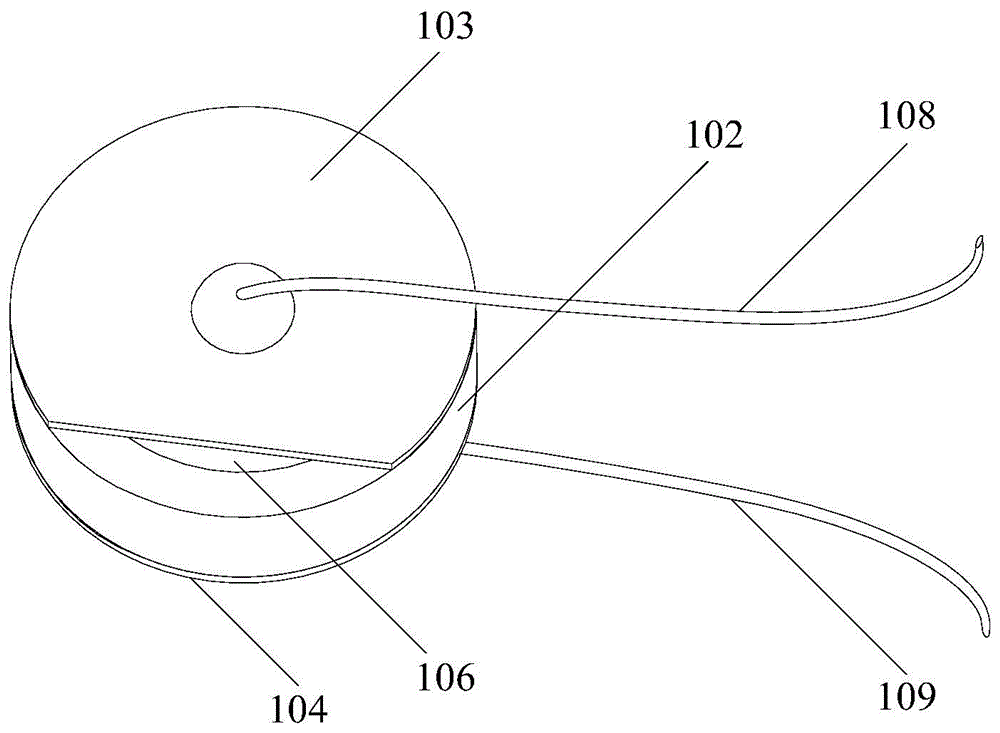

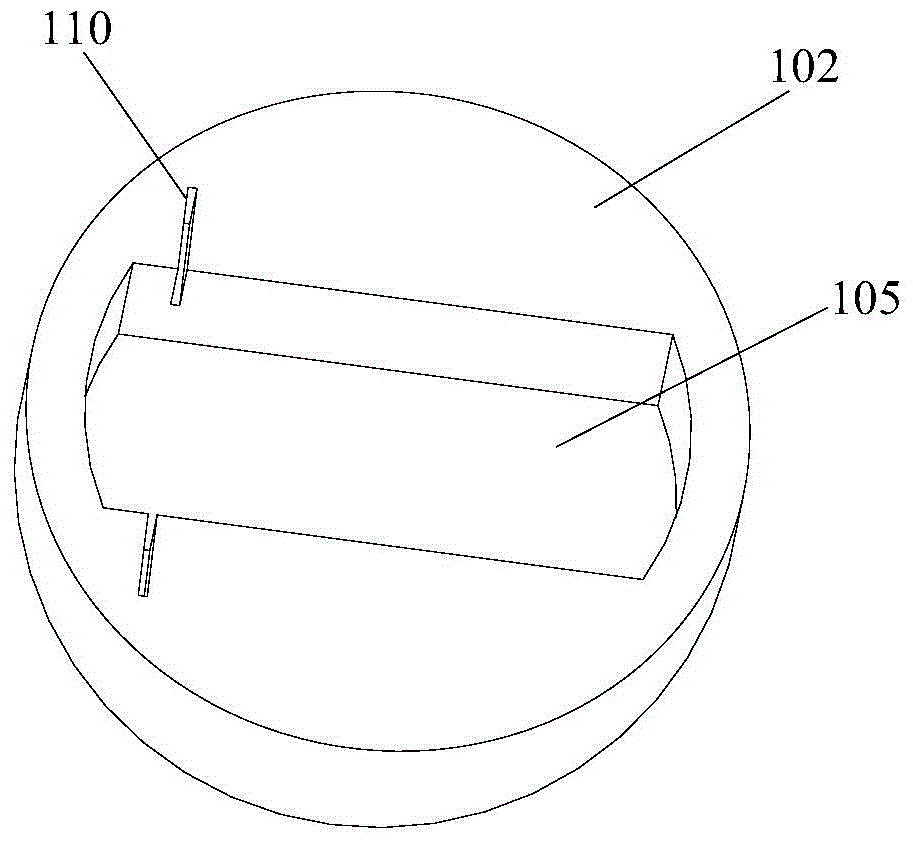

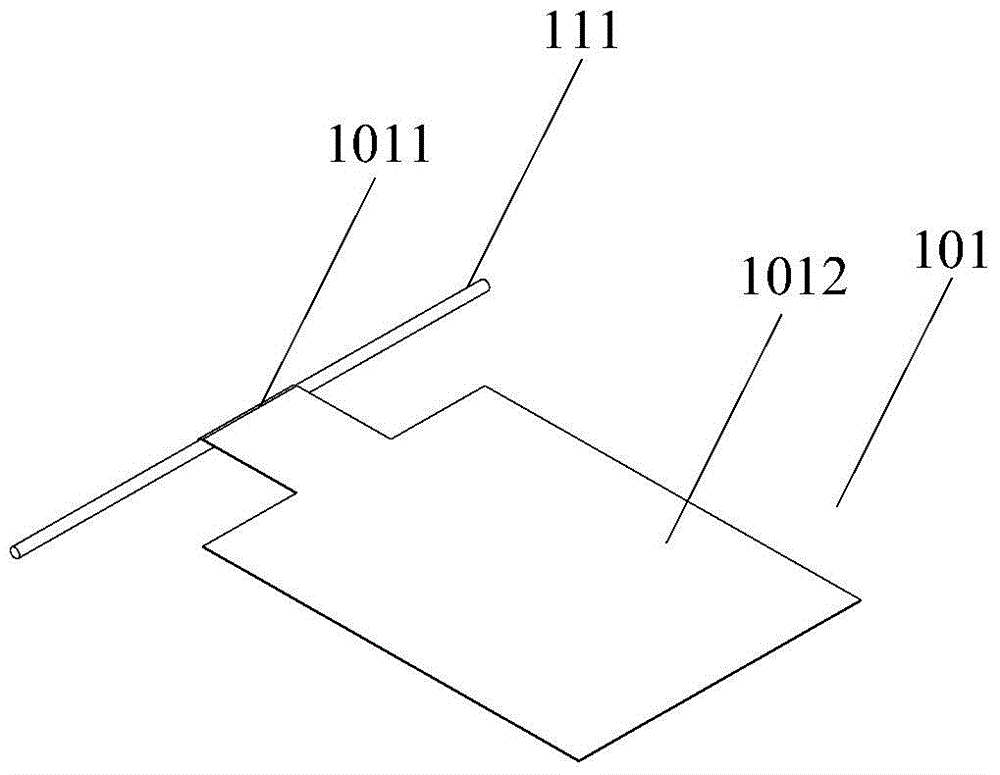

[0057] A pneumatic sensor provided by the present invention has an air inlet and an air outlet, and the pneumatic sensor includes: a first friction component, a casing, a second friction component and a third friction component. Wherein, the housing has a hollow structure with a predetermined shape to form an airflow channel, and the airflow channel communicates with the air inlet and the air outlet, so that air flows into the airflow channel through the air inlet and flows out through the air outlet. The first friction member is arranged in the air flow passage, and the second friction member and the third friction member are arranged at positions capable of contacting the first friction member. When the airflow enters the airflow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com