An amplifying device for continuously amplifying displacement

A technology for amplifying devices and displacements, applied in the direction of transmitting sensing components using fluid devices, can solve problems such as high cost, noise pollution, and large installation space, and achieve continuous adjustable magnification, strong applicability, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

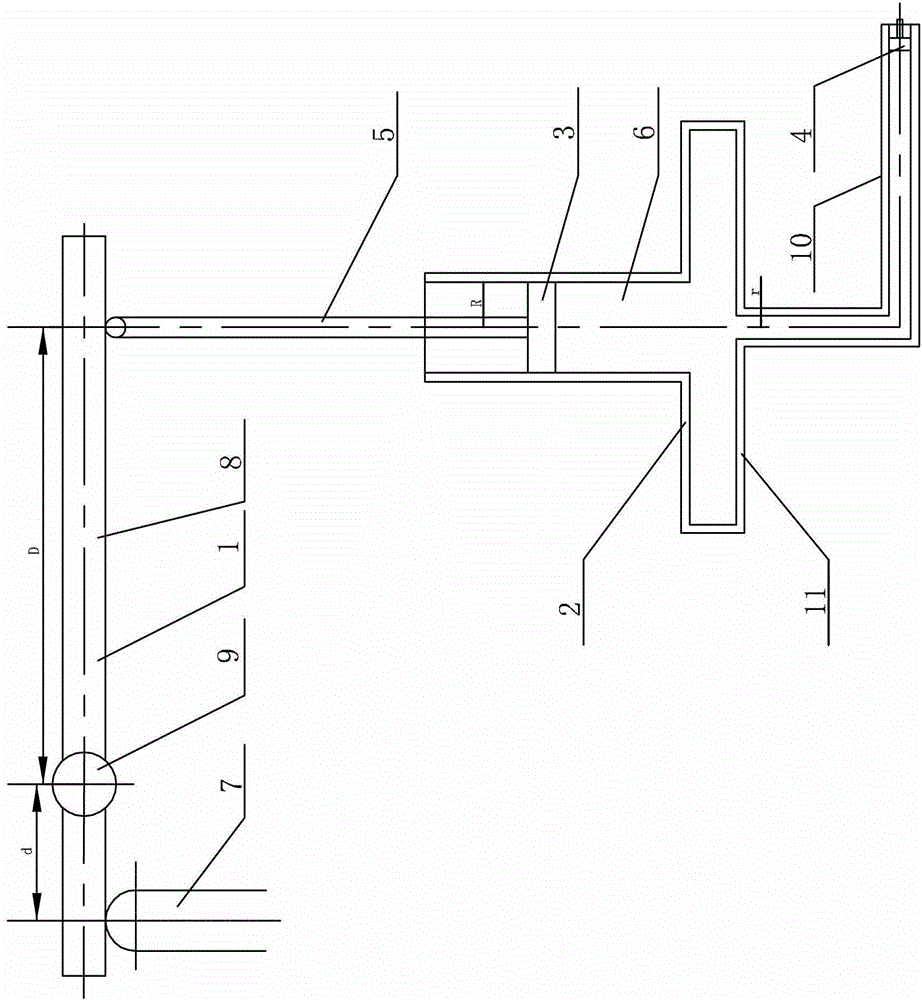

[0007] Embodiment 1: Combining figure 1 Describe an amplifying device for continuously amplifying the displacement in this embodiment, the device includes a lever structure 1 and a hydraulic cylinder mechanism 2, the lever structure 1 includes a push column 7, a lever 8 and a support shaft 9, and the hydraulic cylinder mechanism 2 includes a first piston 3. The second piston 4, connecting rod 5, hydraulic oil 6, hydraulic cylinder 11 and oil outlet pipe 10; the cross section of the hydraulic cylinder 11 is an inverted 'T' shape, the cross section of the oil outlet pipe 10 is an 'L' shape, and the lever 8 passes through the support shaft 9, and the axis of the lever 8 is perpendicular to the axis of the support shaft 9, the upper end of the push column 7 is arranged below the left end of the lever 8, the upper end of the hydraulic cylinder 11 is open, and one end of the oil outlet pipe 10 is connected to the bottom of the hydraulic cylinder 11. The middle part of the lower end ...

specific Embodiment approach 2

[0008] Specific implementation mode 2: Combining figure 1 Describe an amplifying device for continuously amplifying displacement in this embodiment, the distance D from the intersection point of the lever 8 and the support shaft 9 to the connecting rod 5 is twice to the distance d from the intersection point of the lever 8 and the support shaft 9 to the top column 7 Twenty times, the displacement of the right end of the lever 8 to the connecting rod 5 is increased by two times to twenty times than the displacement of the push column 7 through the lever structure 1, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation three: combination figure 1 This embodiment is an amplifying device for continuously amplifying the displacement. The inner radius R of the upper part of the hydraulic cylinder 11 is two to ten times the radius r of the oil outlet pipe 10, and the second piston 4 of the hydraulic cylinder mechanism 2 moves to the right. The displacement is two times to ten times that of the downward movement of the first piston 3, and the others are the same as in the first embodiment.

[0010] working principle

[0011] When the present invention works, push the top column 7 to move upward, the top column 7 drives the left end of the lever 8 to move upward, and the right end of the lever 8 moves downward through the principle of leverage, and then pushes the first piston 3 to move downward. Since the hydraulic oil 6 is incompressible, Push the piston 4 to move to the right, and the displacement of the second piston to the right is more than four times the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com