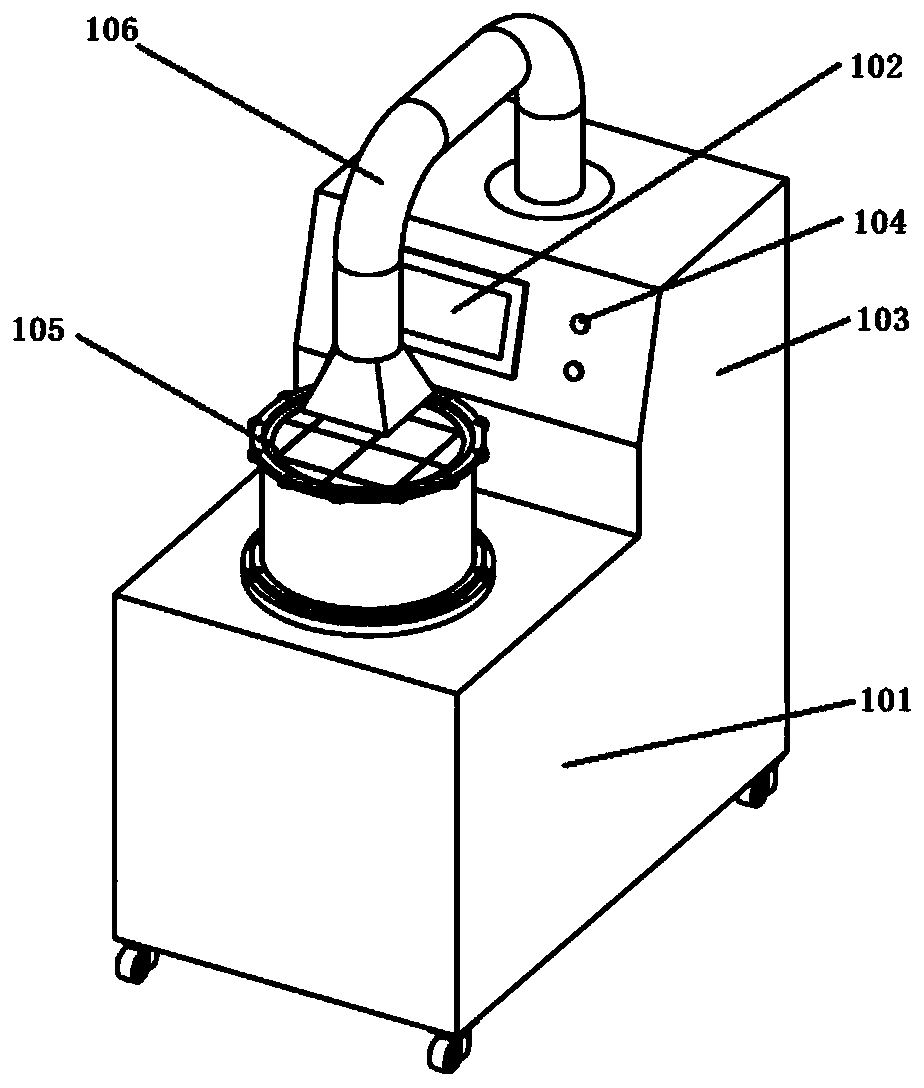

Function tester for DPF/GPF carrier

A technology of DPF and tester, which is applied in the field of vehicle exhaust purification, can solve problems such as complex methods, and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

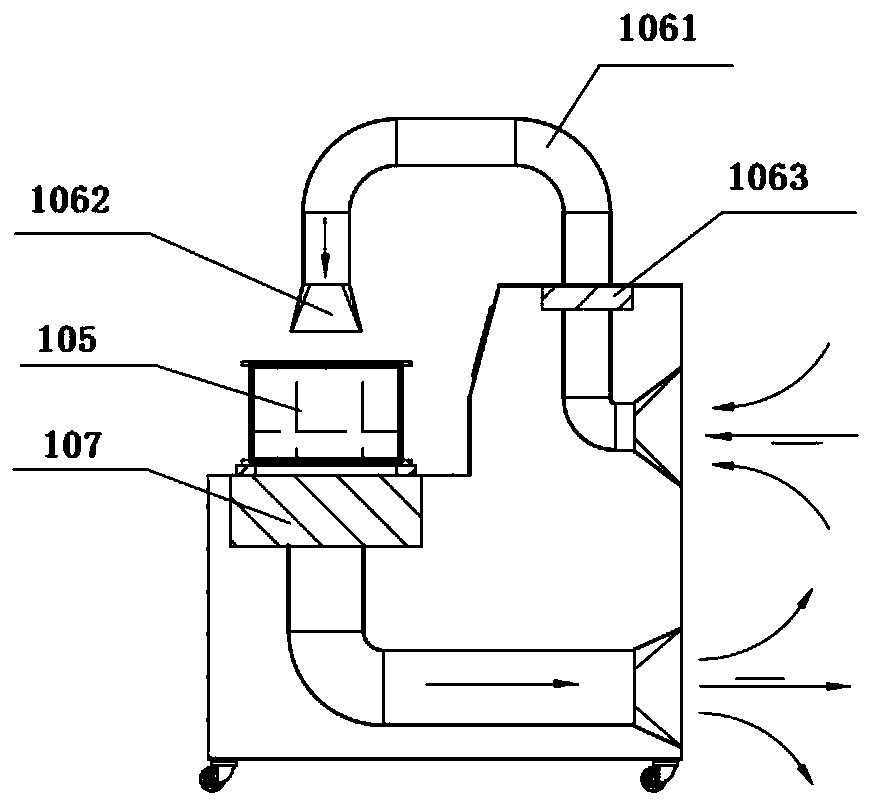

Method used

Image

Examples

Embodiment

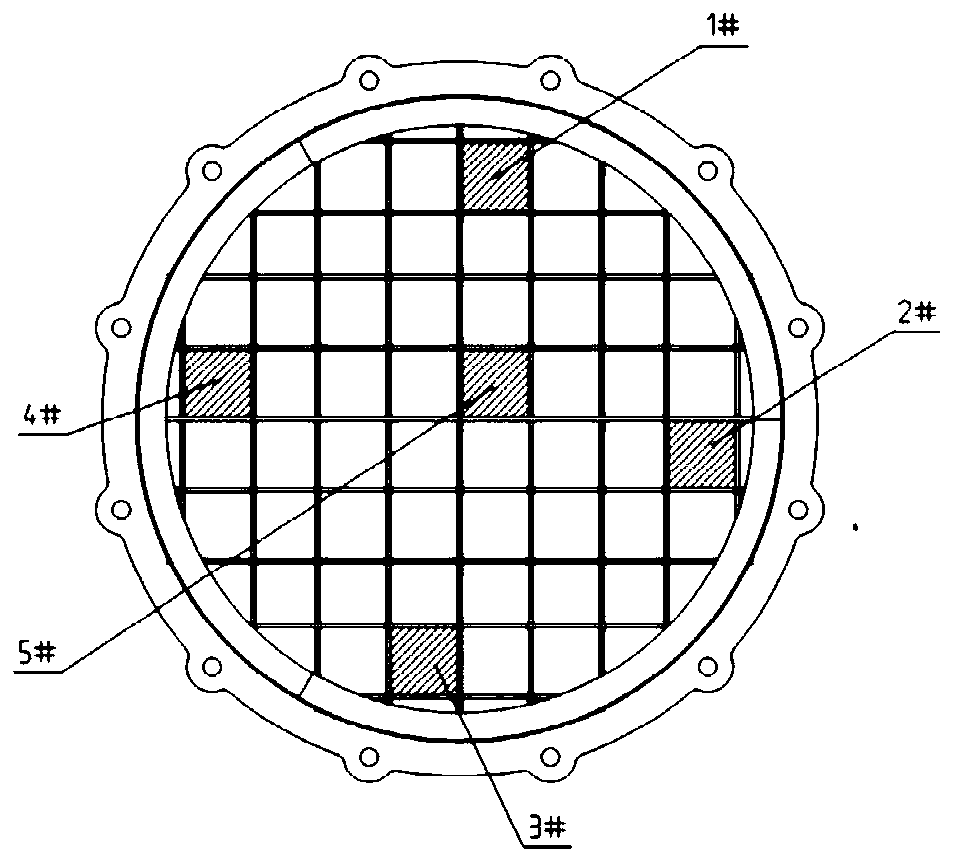

[0032] Example: Measuring the wind speed of a DPF

[0033] 1. Obtain the standard wind speed threshold of an unused DPF

[0034] Take 20 unused recrystallized silicon carbide DPFs manufactured by Guizhou Huangdi Technology Co., Ltd., 10 of which have a diameter of 191mm and the other 10 have a diameter of 286mm. The 20 DPFs are placed on the function tester according to the present invention, and the wind speed is tested for 5 times with a test head with a suitable diameter and a test head with a 1 / 4 fan-shaped section, and the average value obtained for each DPF is used as a standard Threshold, the standard threshold of 191mm is 1.52±0.23m / s, and the standard threshold of 286mm is 1.45±0.15m / s.

[0035] 2. Obtain the real-time wind speed value of the used DPF with blockage

[0036] Take 10 recrystallized silicon carbide DPFs sold by Guizhou Huangdi Technology Co., Ltd. that have passed the test and become clogged after use, of which 5 have a diameter of 191mm and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com