Fully-closed oil tank dehydration system

An airtight, fully airtight technology, applied in mechanical dehydration/demulsification, multi-stage series refining process treatment, etc., can solve threats to the health and life safety of on-site workers, potential safety hazards, high oil viscosity, etc. problems, to achieve the effect of improving dehydration efficiency and oil utilization, safe and reliable use, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

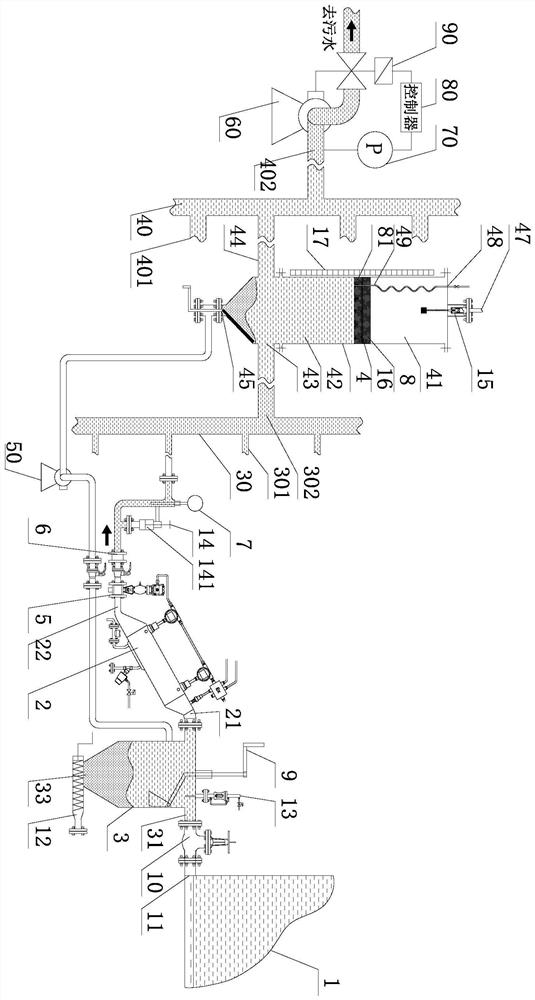

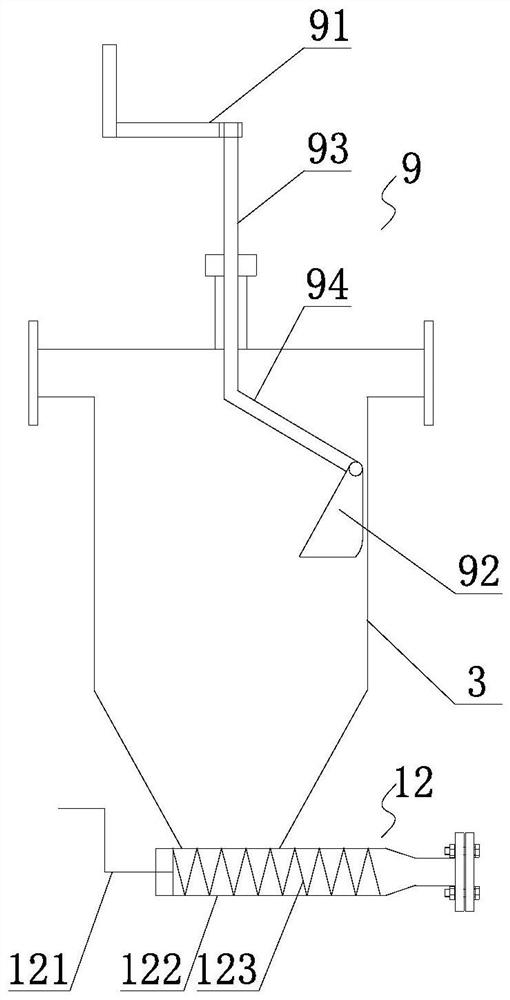

[0041] A fully enclosed oil tank dehydration system according to the present invention includes an oil storage tank 1 and a dehydrator 2, and also includes a sand settling tank 3, and the sand settling tank 3 is installed in the oil storage tank through a connecting pipeline and a tank root valve 10 Between the bottom drain port 11 of the tank 1 and the water inlet end 21 of the dehydrator 2, the grit settling tank 3 includes a top inlet 31 connected to the bottom drain port 11 of the oil storage tank 1, and connected to the top of the dehydrator 2 The connected top outlet 32 also includes an outlet 33 for outputting bottom sediment;

[0042] Buffer tank 4: connected to the water outlet end 22 of the dehydrator 2 through a connecting pipe. The connecting pipe is provided with a dehydration valve 5, a one-way valve 6 and an oil-water detection sensor 7 in sequence. The suspension piston 8 on the liquid surface, the piston 8 divides the buffer tank 4 into an upper adjustment a...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 5 As shown, the scraper 92' is in the shape of a straight plate, and the upright rod 93' of the rocker is movably connected with the inclined rod 94'. By turning the wrench 91, the rocker and the scraper 92 can also be driven to rotate together. So as to carry out effective mud scraping work.

Embodiment 3

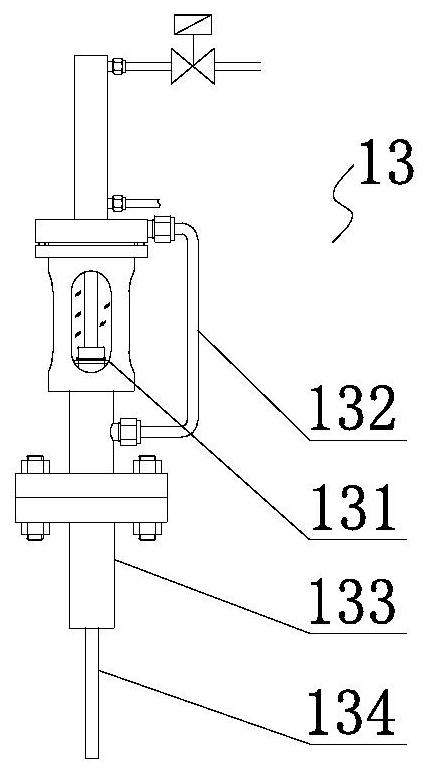

[0062] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 6 As shown, the breathing port 47 is provided with a switch valve 15 that can automatically close the breathing port 47, and the valve body of the switching valve 15 is provided with a valve core 151 for blocking the breathing port, and the bottom of the valve core 151 is connected to One is provided with a valve stem 153 equipped with a lever type touch switch 152', the end of the valve stem 153 is connected with a connecting chain 154, and a weight 20 is hung at the end of the connecting chain 154, and the piston 8 moves along with the lower storage. When the liquid level in the liquid area 42 rises, the weight 20 lifts the spool 151 and closes the breathing port 47, and the piston 8 stops moving up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com