A method for detecting laser cutting nozzle plugging

A laser cutting and cutting nozzle technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cutting nozzle clogging, blocking laser beam transmission, and excessive waste, and achieves low cost, simple and convenient detection, and detection precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

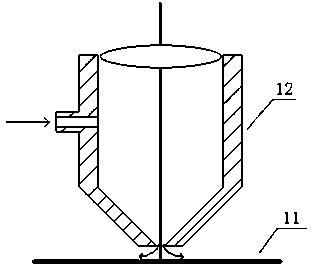

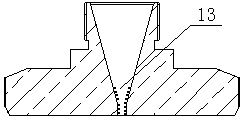

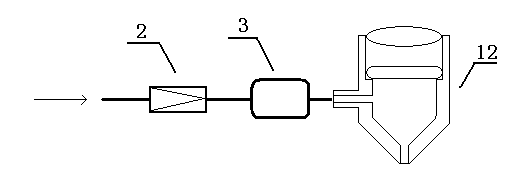

[0016] refer to figure 1 , image 3 , a method for detecting laser cutting nozzle clogging, which judges the clogging situation of the cutting nozzle 12 by detecting the change of the compressed air flow inside the cutting nozzle in real time; when the compressed air flow decreases to a set range, the cutting nozzle 12 is prompted clogged. Specifically, the following method is adopted: the compressed air enters the flow sensor 3 through the pressure reducing valve 2, and then enters the cutting nozzle 12 for coaxial air blowing. The flow sensor 3 detects the flow rate of the compressed air in real time, and transmits the flow signal to the signal processing module. The processing module processes the flow signal, and when the flow information is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com