Cutter head wear detection device for shield machine

A detection device and shield machine technology, which is applied in the field of shield machines, can solve problems such as increasing structural installation space and economic costs, entering shutdown, entering warehouse inspection, and reducing pressure, so as to ensure safety and stability, and save energy. Space and cost, the effect of compact installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

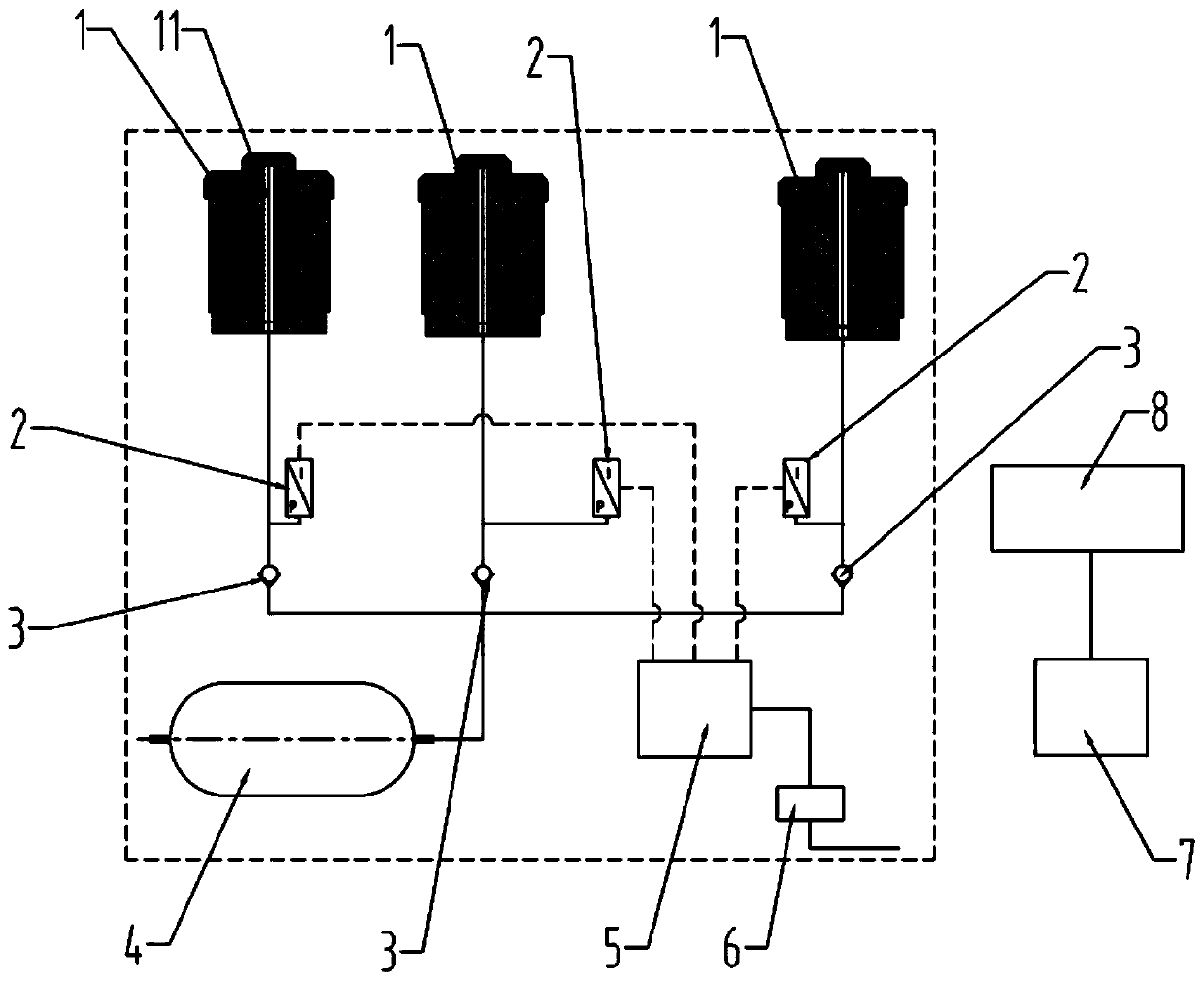

[0021] Refer to figure 1 , Is a cutter head wear detection device for shield machine according to the present invention, including a detection head 1, a pressure sensor 2, a one-way 3, a gas cylinder 4, a signal transmitter 5, a conductive slip ring 6 and a signal receiver 7 .

[0022] The detection head 1 is a steel workpiece, and a detection hole 11 is machined inside, and the detection hole is a blind hole. The detection head 1 is welded to the cutter head panel or the circumference of the cutter head, and multiple detection heads 1 can be welded according to actual conditions.

[0023] The gas cylinder 4 is fixed near the flange of the cutter head of the shield machine. The gas cylinder 4 is filled with compressed air. The open end of the detection hole of each detection head 1 is connected to the gas cylinder 4 through a pipeline. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com